14

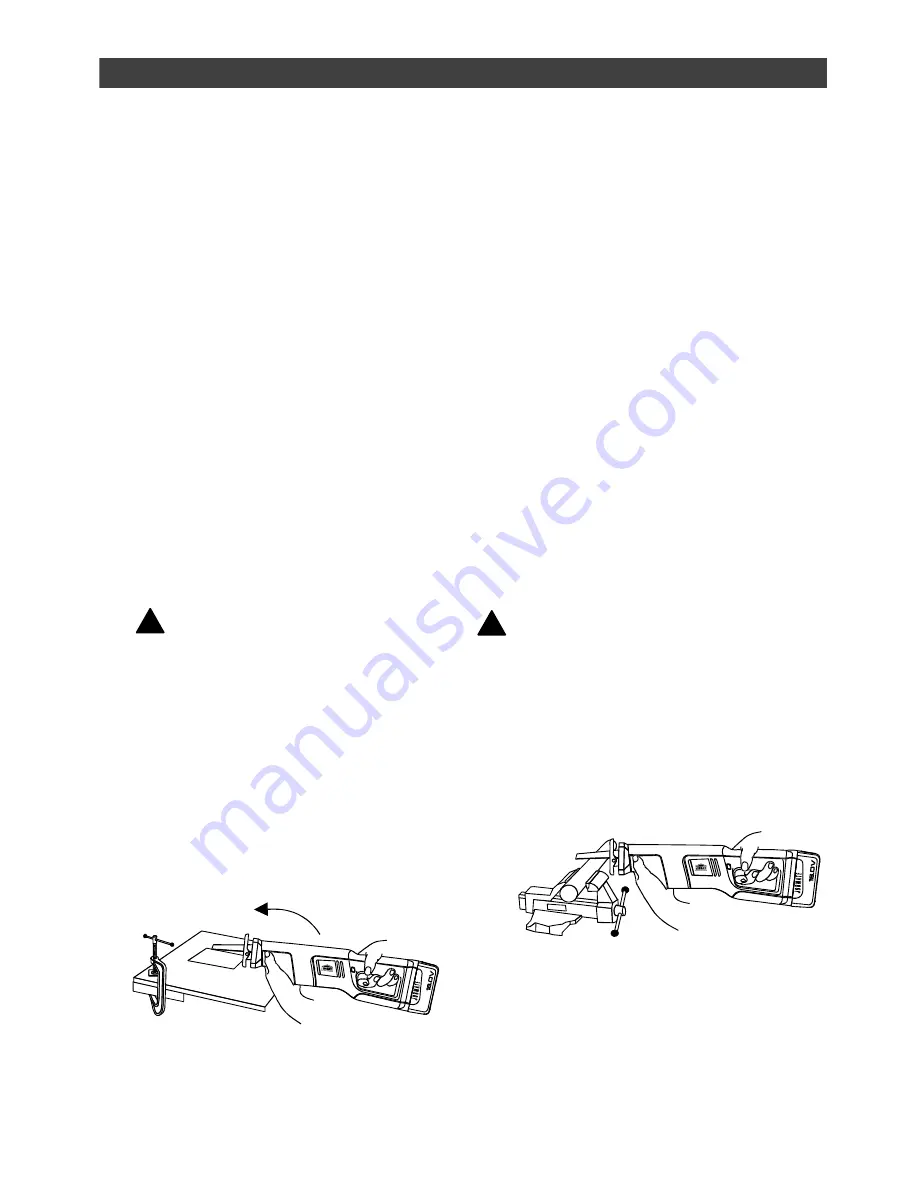

PLUNGE CUTTING

1. Clearly mark the workpiece to locate

the position of the cut.

2. Clamp the workpiece to a work bench

or table (Fig. 6).

NOTE:

Make sure the area to be cut is

clear under the workpiece so that the

blade will not come into contact with

anything other than the workpiece.

3. Select a convenient starting point in

the area to be cut out. Place the tip of

the blade over that point.

4. Rest the lower edge of the adjustable

pivoting shoe on the workpiece and

hold it firmly in that position.

5. Depress the lock-off button and

squeeze the trigger switch to start the

saw.

WARNING:

Make sure the

blade does not touch the workpiece

until the saw reaches full speed.

Loss of control and possible injury

could result.

6. With the saw running at full speed,

slowly tilt the saw until the tip of the

blade contacts the workpiece and

begins to cut. After the blade cuts

through the workpiece, tilt the saw

upward until the blade is perpendicular

to the workpiece.

METAL CUTTING

Metals such as pipe, steel rods, sheet

steel, aluminum, brass and copper can be

cut with your saw (Fig. 7).

●

To cut thin sheet material, “sandwich”

the material between hardboard or

plywood and clamp the layers to limit

vibration and material tearing.

●

Always use a fine tooth metal cutting

blade and run the saw at medium

speeds when cutting metal.

●

Use cutting oil to keep blade cool,

increase cutting action and prolong

blade life.

●

Do not twist or bend saw blade.

●

Do not force the saw blade. Let it cut

at its own speed.

DANGER:

a) Always clamp workpiece in a vise or

to a workbench or table. Do not

hold workpiece in your hand.

b) Never use gasoline as a lubricant or

as a cleaning agent. A spark from

the motor may cause an explosion.

Gasoline will also damage the

plastic components of the saw.

!

!

OPERATION

Fig. 6

Fig. 7