Service hotline

:

+86 523-84385453

- 6 -

the end, no matter the spindle is working or the tool is changing, “air

sealed” should be activated all the time unless the whole CNC machine

stops, which is to avoid the pollution from cooling liquid or the cutting

chips.

⑾ 、

There is thermistor inside the spindle stator, with the model

103F3950

,

R25:10K 1% B: 3950K

。

It’s used to detect the temperature

inside the spindle.

2. 5

、

Air connection & steps of tool change

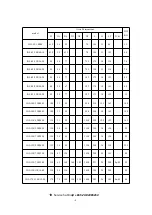

According to the labels at the back of spindle, connect “air inlet”,

“dust removal”, “air return” and “air sealed”. Adjust the pressure as

following:

air inlet: to release the tool holder, 0.6~0.7 mpa,

dust removal: to clean the dust off the internal of rotor, 0.4~0.5 mpa

air return: to make the air cylinder return to its initial position,

0.6~0.7 mpa

air sealed: to clean the dust & chips off the external of spindle

waterway , 0.1~0.2 mpa

To change the tool, please see the steps as following:

(1) Control the valve for tool released, pressurize “air inlet” for

3~5s. At this moment, clamp inside the spindle cone will open.

(2) Control the valve of “dust removal” and pressurize it at the

pressure 0.4~0.5 mpa.

(3) Insert the tool holder into spindle cone till the cone top.

(4) Turn off the valve of “air inlet” and “dust removal” at the

same time. Discharge the air inside the cylinder through exhaust. Now the