27

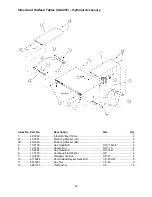

Tracker Kit (98-0080)

Trackers dramatically reduce tracking adjust-

ments of conveyor belts. They are already

installed on your sander. The following

information is for re-setting or replacing your

trackers, should that become necessary. Refer

to Figure 43.

1. Disconnect power to sander, and disconnect

motor cord from control box receptacle.

2. Lower conveyor table as far as it will go.

3. Loosen the conveyor take-up screw nuts to

relieve conveyor belt tension and slide

driven roller fully inward. Slide conveyor belt

to one side of bed.

4. Remove the four bolts holding the conveyor

table to the sander base.

5. Lift conveyor table and slide it out of the

sander. Turn conveyor table upside down.

Be careful not to damage the conveyor belt.

6. On the underside of the conveyor bed, there

are U-channels welded to the bed. The

Tracker is positioned on the inside of the

first U-channel on the infeed side of sander

(the U-channel closest to the rubber covered

drive roller and gear motor). The back of the

Tracker is magnetized and will stick to the

side wall of the conveyor bed. Do not install

Tracker if the edge of the conveyor belt is

damaged or torn.

7. With the first Tracker installed, slide the

conveyor belt into the bottom slot of the

Tracker. Note: When installed properly, only

the bottom lip of the Tracker will be visible.

The top slot is to be used if the bottom slot

wears out.

8. Install second Tracker opposite the first. Use

both Trackers unless the second one does

not fit in conveyor or if conveyor belt is

damaged.

9. Turn conveyor table right-side up and re-

position it onto the sander. Re-attach the

four mounting bolts and tighten. Caution:

Be careful not to knock Tracker(s) out of

conveyor bed when turning conveyor over.

10. Make sure all switches are off. Connect

power to sander and plug in motor.

11. Tension the conveyor belt using take-up

screw nuts. If both Trackers are installed, it

is very important to have equal tension on

both sides of the conveyor belt. Tighten both

sides of take-up screw nuts until equal

tension is obtained.

12. To check tension, turn on conveyor full

speed and place both hands on conveyor. If

conveyor belt can be stopped, continue

tensioning until conveyor belt cannot be

stopped by both hands on the belt while the

conveyor is operating at full speed.

13. Make sure conveyor belt runs smoothly

inside Tracker slot and that the magnet is

holding the Tracker in position.

14. Continue to watch tracking of conveyor and

adjust only if necessary, making sure to

keep equal tension on conveyor belt at all

times and not allowing conveyor belt to

buckle under conveyor bed.

Figure 43 (underside of conveyor shown)

Содержание SandSmart 22-44 Pro

Страница 34: ...34 Stand Assembly...

Страница 36: ...36 Drum Head Assembly...

Страница 38: ...38 Conveyor and Motor Assembly...

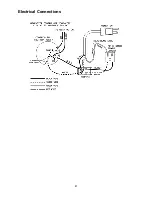

Страница 41: ...41 Electrical Connections...

Страница 42: ...42 NOTES...

Страница 43: ...43...

Страница 44: ...44 WMH Tool Group 2420 Vantage Drive Elgin Illinois 60123 Phone 800 274 6848 www wmhtoolgroup com...