13

TIP:

On rough lumber, you may need to rip one

edge on a table saw or band saw to more easily

observe a board’s grain direction. Also, the grain on

some wood species may change direction in the

middle of the board – if possible, cut the board in the

middle so the grain direction will be consistent on

both pieces. Otherwise, use personal judgment as

to which direction is more favorable, and safer, for

feeding.

Edge grain (see Figure 9-2) may be planed if the

stock is wide enough to rest firmly upon the table.

Do not attempt to plane end-grain

(see Figure 9-

2) as this can result in splintering of the stock and

potential kickback.

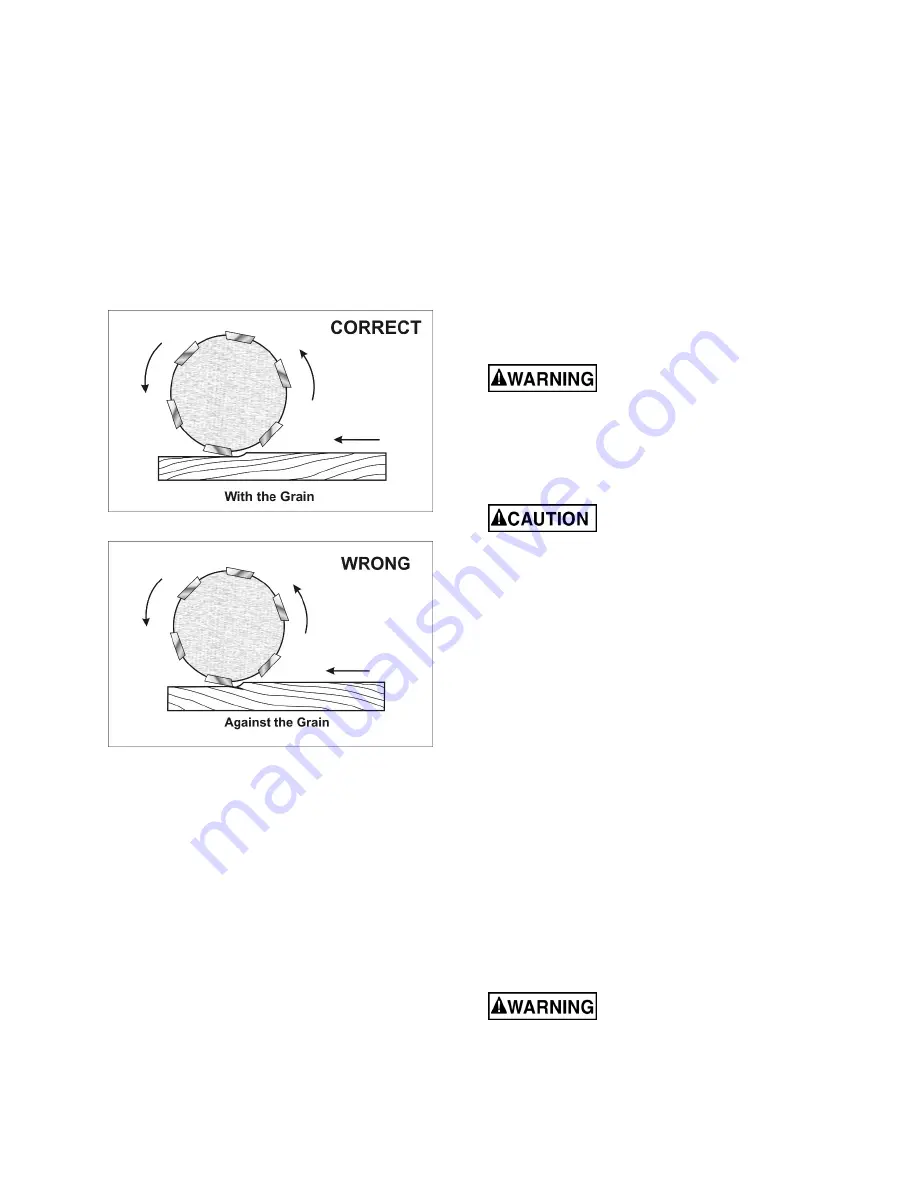

Figure 9-3

Figure 9-4

9.8

Knots and trouble spots

Wood with knots, “wild” grain, or extensive figuring

is always difficult to surface and requires extra care.

Check that any knots are solid. Do not plane stock

with loose knots. Take light cuts. Be especially

cautious of kickbacks and stop cutting immediately

if the board will not feed smoothly.

9.9

Snipe

Snipe refers to a depression at either end of the

board caused by an uneven force on the cutterhead

when the work is entering or leaving the planer.

Snipe may occur when the board is not supported

properly or when only one feed roller is in contact

with the board at the beginning or end of the cut.

If the snipe is deep, be more careful how the board

is supported. Keep it parallel to and flat on the table

at all times. Use an extra support, such as a roller

stand, at both the infeed and outfeed ends of the

planer.

Other methods to prevent snipe are reducing the

depth of cut, and feeding additional boards butted

closely to leading and trailing ends of the workpiece.

If snipe cannot be avoided, cut the material longer

than needed and trim the ends after planing.

9.10

Ridges

Damaged or nicked knives can leave ridges along

the length of a board.

Always inspect each board carefully before

attempting to plane it. Do not attempt to plane

second-hand lumber with nails below the surface,

painted wood, plywood, hardboard, wood with a

glue bead, or any material other than solid wood.

Do not attempt to plane

second-hand lumber, painted or varnished

wood, plywood or particle board. These

materials can damage planer knives. Failure to

comply may cause serious injury.

9.11

Planing rough lumber

Make sure wood is properly

dried before planing. Wet or “green” lumber may

clog the machine and lead to damage.

Air dried wood should stand for at least a year per

inch of thickness of the rough cut stock. The

moisture content of air dried wood should be about

12% to 15%. Kiln dried woods should have a

moisture content of approximately 10%. Wood to be

used in fine furniture should have a moisture content

of 7% to 8%.

Joint one edge of the rough cut lumber before

planing. This will help you determine the direction of

grain travel. Feed the board into the planer so the

knives cut with the grain, see Figure 9-3.

Measure the rough lumber at several locations to

find the thickest part. As wood dries, its dimensions

vary, including its thickness. Set the planer to take a

very shallow cut on the highest, thickest part of the

board. Continue to take very shallow cuts until you

can determine whether there are any knots or

unusual grain patterns.

After completing one side, inspect the opposite side

for irregularities, then process it using the same

procedure as for the first side.

9.12

Planing glued-up boards

Glued-up stock must dry at

least 24 hours before being planed. Failure to

comply may cause the stock to separate in the

planer, leading to kickback and serious injury.

Содержание JWP-13BT

Страница 20: ...20 12 1 1 Base Assembly Exploded View ...

Страница 22: ...22 12 2 1 Head Assembly Exploded View ...