11

7.6

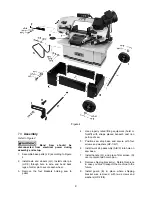

Coolant system

Make sure there is coolant in

the tank before operating, to prevent damage to

pump.

Use of a water-soluble coolant will increase cutting

efficiency and prolong blade life. Do not use black

cutting oil as a substitute.

1. Remove coolant return hose (A, Figure 10)

from filter cup, and slide tank out of saw base.

2. Fill tank to approximately 80% of capacity. Full

capacity is 9 liters (2.5 gal).

3. Place tank into base. Place coolant return

hose into the filter cup. Verify that opposite

end of coolant return hose is connected to the

coolant pan.

4. The coolant supply hose (B, Figure 17) should

connect to the two valves on the blade guide

assemblies.

Figure 10

8.0

Electrical connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

The HVBS-710SG Band Saw is rated at 115/230V

power, and pre-wired for 115 volt. The band saw

comes with a plug designed for use on a circuit

with a

grounded outlet

that looks like the one

pictured in

A

, Figure 11.

Before connecting to power source, be sure switch

is in

off

position.

It is recommended that the band saw, when

operated at 115 volt, be connected to a dedicated

20 amp circuit with a 20 amp circuit breaker or

time-delay fuse rated “D”. It is recommended that

the band saw, when operated at 230 volt, be

connected to a dedicated 15 amp circuit with a 15

amp circuit breaker or time-delay fuse rated “D”

Local codes take precedence over recom-

mendations.

8.1

Grounding instructions

1. All Grounded, Cord-connected Tools:

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric shock.

This tool is equipped with an electric cord having

an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a

qualified electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-

grounding conductor to a live terminal.

Check with a qualified

electrician or service pe

r

sonnel if the

grounding instructions are not completely

understood, or if in doubt as to whether the

tool is properly grounded. Failure to comply

may cause serious or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug.

Repair or replace damaged or worn cord

immediately.

2. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

less

than 150

volts:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in

A,

Figure

11. An adapter, shown in

B

and

C

, may be used to

connect this plug to a 2-pole receptacle as shown

in

B

if a properly grounded outlet is not available.

The temporary adapter should be used only until a

properly grounded outlet can be installed by a

qualified electrician.

This adapter is not permitted

in Canada.

The green-colored rigid ear, lug, and the like,

extending from the adapter must be connected to a

permanent ground such as a properly grounded

outlet box.

3. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

between

150 - 250 volts

, inclusive:

Содержание HVBS-710G

Страница 23: ...23 14 1 1 HVBS 710SG Table and Stand Assembly Exploded View...

Страница 24: ...24 14 1 2 HVBS 710SG Bow Assembly Exploded View...

Страница 29: ...29 14 2 1 HVBS 710SG Gearbox Assembly Exploded View...

Страница 31: ...31 15 0 Electrical Connections for HVBS 710SG...

Страница 32: ...32 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...