11

Note:

When raising the roller higher above the

table, the available range is from .003” to .006”

See Fig. 13.

The table rollers are factory set for average

planing and are parallel to the table surface. If you

desire to adjust the table rollers higher or lower,

proceed as follows:

1. Disconnect machine from power source.

2. Lay a straight edge (B, Fig. 14) across both

rollers.

3. On one side of the table, loosen the screws

(C, Fig. 14) with a hex wrench, and turn the

eccentric shafts (D, Fig. 14) to raise or lower

the rollers.

4. When the proper height is achieved, tighten

screws (C, Fig. 14).

5. Adjust the rollers from the opposite side of the

table in the same manner.

Important:

Be sure that the height of front and

rear rollers are the same. The table rollers must

always be set parallel to the table.

Adjusting Table Extension Rollers

1. Place a straight edge over the extension roller

and the table, as shown in Fig. 15, to make

sure the extension roller and table are at the

same height. If necessary, adjust the table

extension rollers as follows:

2. Loosen the screws and washers (A, Fig. 15)

to move the extension roller to the proper

position, then retighten the screws.

3. Adjust both front and rear extension rollers in

the same manner.

Figure 13

Figure 14

Figure 15

Содержание 708528

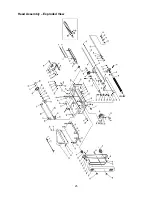

Страница 25: ...25 Head Assembly Exploded View ...

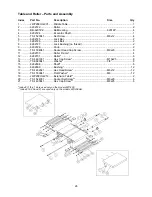

Страница 29: ...29 Base and Column Assembly ...

Страница 31: ...31 Gearbox Assembly ...

Страница 32: ...32 Wiring Diagrams 230V 3HP Single Phase A2 14NO 17 13NO O ManAuto 97 95 96 98 R R 4T2 6T3 2T1 3L2 5L3 1L1 A1 ...

Страница 33: ...33 230V 5HP Single Phase A2 14NO 17 13NO O ManAuto 97 95 96 98 R R 4T2 6T3 2T1 3L2 5L3 1L1 A1 ...

Страница 34: ...34 230V 5HP Three Phase 4T2 ManAuto 97 A2 95 R 96 O R 14NO 6T3 17 98 2T1 3L2 13NO 5L3 1L1 A1 ...

Страница 35: ...35 460V 5HP Three Phase 4T2 ManAuto 97 A2 95 R 96 O R 14NO 6T3 17 98 2T1 3L2 13NO 5L3 1L1 A1 ...

Страница 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...