18

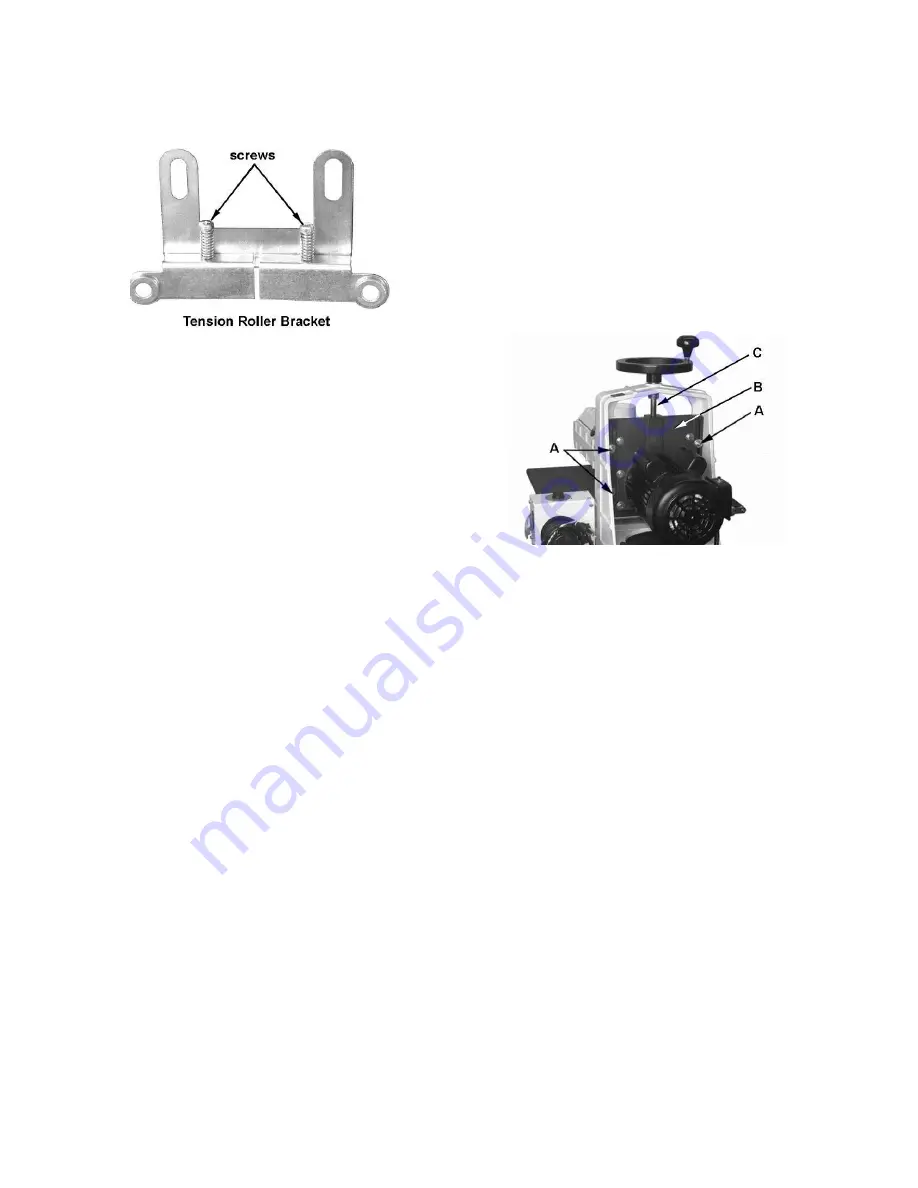

Tension Roller Pressure Adjustment

You can increase or decrease tension roller

pressure by turning the screws on the tension

roller brackets (Figure 25).

Figure 25

Too much tension roller pressure can result in a

“snipe” mark, which is identified as a visible line

running across the width of the board and

located approximately 2-1/4” from the end of the

board.

If the snipe occurs on the leading end of the

board, adjust the outfeed tension roller. If the

snipe occurs on the trailing end of the board,

adjust the infeed tension roller.

Tension roller pressure can also be adjusted by

raising the height of the rollers, as follows:

1. Repeat “Tension Roller Alignment” except

raise the sanding drum only 1/4 turn of the

height adjustment handle.

2. If both tension rollers are causing snipe then

tighten all four hex nuts (E, Fig. 24) at this

position.

3. If only outfeed tension roller causes snipe,

only tighten rear (outfeed) hex nuts on each

end of drum at this position, then raise

sanding drum another 3/4 turn of the handle.

4. Press infeed tension roller down to rest on

conveyor bed and tighten front (infeed) hex

nuts at this position.

This process sets the tension roller assembly at

an angle providing less tension pressure on the

outfeed roller.

Drum Height Control Adjustment

If the height control mechanism does not

operate easily or smoothly or there is excessive

vertical movement or deflection of the drum

carriage, perform the following adjustments.

1. Tighten all four lock nuts (A, Fig. 26) and

then loosen them 1/8 to 1/4 turn. If the lock

nuts are set too tight, height control will not

operate easily. If the lock nuts are too loose,

excessive deflection of the outboard end of

the drum carriage will result.

2. Thoroughly lubricate the mating surfaces of

the motor mount slide (B, Fig. 26), and the

height adjustment screw (C, Fig. 26).

Figure 26

Содержание 22-44 OSC

Страница 27: ...27 Drum Head Assembly Exploded View...

Страница 30: ...30 Conveyor and Motor Assembly Exploded View...

Страница 35: ...35 Wiring Diagram...

Страница 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...