16

Conveyor Belt Replacement

1. Unplug the machine from the wall

receptacle, and unplug the motor cord from

the control box receptacle.

2. Raise drum to its highest position using the

handwheel.

3. Loosen the conveyor take-up screw nuts

(A, Fig. 20) to relieve belt tension, and slide

the driven roller fully inward.

4. Remove the four bolts that attach the

conveyor table to the base. Lift up the

conveyor table and remove it from machine.

Avoid tearing the belt on any edges

underneath the conveyor bed.

5. Install new belt, and re-install conveyor

table. Take care not to damage the

Trackers. Tension and track the new belt.

Note:

If the conveyor belt continually tracks to

one side of the machine, reversing the belt on

the conveyor bed may remedy the problem. To

make sure the conveyor bed is not twisted,

place a level on the conveyor bed. Level the

machine if needed. If there is still a problem,

proceed with the steps below:

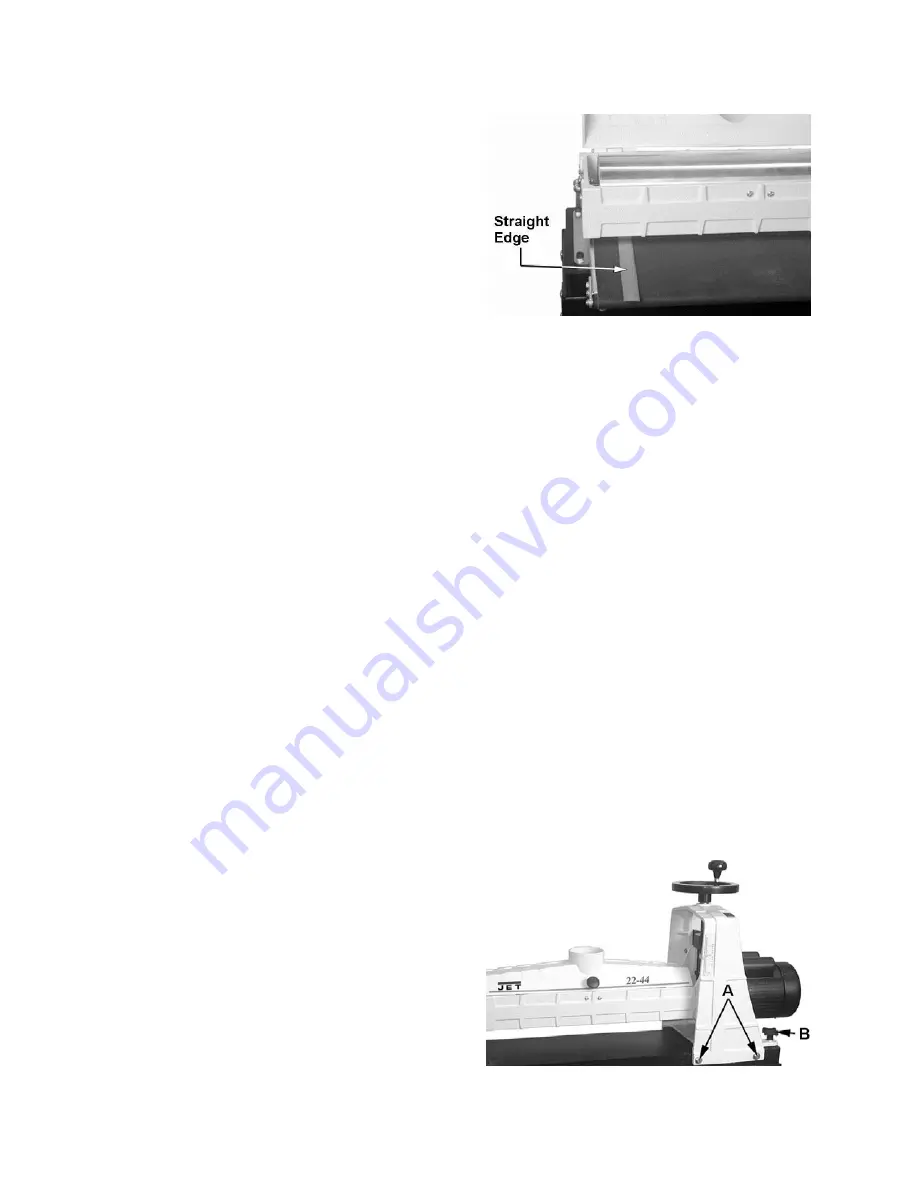

Step 1

: Check the conveyor drive roller and the

driven roller to make sure they are parallel to the

surface of the conveyor bed. To do this, first

center the conveyor belt on the bed. Then lay a

straight-edge on the exposed edge of the

conveyor bed on the left (outboard) side,

extending it over the roller. Note the distance

between the roller and the straightedge.

Step 2:

Now repeat Step 1 on the right (inboard)

side of conveyor. Compare the measurements

from side to side. If they are not equal, loosen

one of the brackets that hold the roller in place.

Tip this bracket until the distance between the

roller and the straight-edge are equal from side

to side, then tighten the bracket.

Checking Drum Alignment

The sanding drum must be aligned parallel to

the conveyor bed for proper machine operation.

The sanding drum comes preset from the

factory. If a problem with the drum alignment

occurs, follow the instructions below.

First inspect the alignment with a gauge of some

kind. The following procedure uses a steel

straight edge as a gauge.

1. Unplug sander from power source.

2. Open the dust cover and remove the

abrasive strip from the drum.

3. Insert gauge between the drum and con-

veyor bed at the outer end of the drum

(Figure 21).

Figure 21

With the dust cover open, lower sanding

drum while slowly rotating drum by hand

until the drum lightly contacts the thickness

gauge.

4. Remove thickness gauge and place under

drum at the other end.

5. If the drum does not contact the thickness

gauge to the same degree as the opposite

end of the drum, alignment is necessary.

To align the drum:

6. Loosen the four 3/8” hex cap screws – two

front, two rear (A, Fig. 22). This allows the

entire drum carriage and shroud to be

pivoted on two screws – one screw in front,

one in back.

7. Lay the thickness gauge under the drum

lengthwise. See Figure 23. Rotate the fine

tune adjustment knob (B, Fig. 22) until the

drum contacts the gauge equally along its

entire surface. Rotate the knob clockwise to

raise the outboard end of the drum,

counterclockwise to lower the outboard end

of the drum. Use the height adjustment

handwheel to raise or lower the entire drum.

8. When drum is parallel to conveyor, tighten

the four screws (A, Fig. 22).

Conveyor table removed for clarity

Figure 22

Содержание 22-44 OSC

Страница 27: ...27 Drum Head Assembly Exploded View...

Страница 30: ...30 Conveyor and Motor Assembly Exploded View...

Страница 35: ...35 Wiring Diagram...

Страница 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...