26

CHUCK JAW DETAIL

Top jaws should be designed to hold the workpiece

as close to the chuck face as possible. Excessive

jaw height reduces the effective gripping force

available and is detrimental to accuracy. As a

general rule, the height of the grip point above the

chuck face should not exceed one quarter of the

chucks’ diameter.

Large, heavy top jaws should be avoided if

possible since the loss of gripping force due to

centrifugal effects at high spindle speeds is

increased. If heavy jaws are unavoidable, it may be

necessary to restrict the spindle speed below the

chucks’ maximum recommended speed to ensure

that sufficient gripping force is retained to hold the

workpiece.

All top jaws in a set should be of equal weight to

ensure that no out-of-balance forces occur. In the

case of workpieces with a residual out-of-balance,

this may be corrected by designing the top jaws to

counteract the imbalance component. Alternatively,

it may be necessary to restrict the machine to low

speeds to avoid possible vibration problems.

Ideally, top jaws should not extend beyond the

chuck periphery. If this is unavoidable, the amount

of projection should be restricted within safe limits

bearing in mind that the loss in gripping force due

to centrifugal effect is a function of the product of

top jaw mass and the distance to the jaws’ centre

of mass about the chucks’ rotational axis.

Precautions should also be taken to ensure that

projecting top jaws will not collide with tooling

during the machining cycle.

Care should be exercised in machining workpieces

whose length protrudes excessively beyond the

chuck jaws. As a general guide, for workpieces up

to approximately one third of the chuck diameter

whose inner end face is located close to the chuck,

machining should not be carried out at a distance

greater than five times the workpiece diameter or

three times the axial length gripped by the jaws

measured from the outer end of the jaws.

The lesser of these values should be used and the

maximum height of the top jawsshould be

restricted to one quarter of the chuck diameter.

The proportions for this condition are shown below.

When the workpiece diameter is greater than approximately

one third of the chuck diameter and the workpiece is well

supported axially close to its outer periphery, the distance to

the machine point from the outer end face of the jaws

should not normally exceed three quarters of the workpiece

diameter. This is based on the assumption that the axial

length of the workpiece gripped by the jaws is not less than

one tenth of the workpiece diameter.

The proportions for this condition are shown below

.

Содержание PRINCE

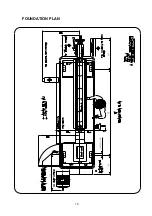

Страница 17: ...16 FOUNDATION PLAN 300 40X4HOLES A 350 500 570 ...

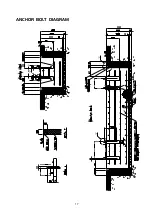

Страница 18: ...17 ANCHOR BOLT DIAGRAM ...

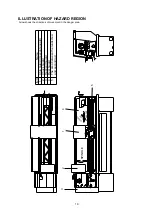

Страница 19: ...18 CONNECTION OF EXTRACTION SYSTEM 18 To Extraction System 18 ...