Testing Procedures

!

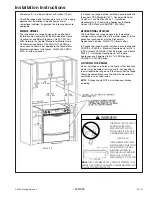

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

16 16022089

©2005 Maytag Services

Illustration Component

Test

Procedure

Results

Bake burner

Verify gas is supplied.

Orifice adjusted for Natural or LP ...........

Check for obstructions or

contamination in ports ............................

Factory set to Natural Gas.

Adjust as necessary.

Air shutter opening set to .469 to .531.

Replace if punctured or torn.

Ignitor

Test for voltage at terminals ...................

Test for the amount of amperage in

the circuit................................................

(Ignitor may glow but not have

sufficient amperage to open valve.)

120 VAC.

3.2

−

3.6 Amps If not replace.

Broil element

Disconnect wiring to element and

measure resistance of terminals.............

Measure voltage at broil element............

Approximately 16

Ω

.

120 VAC.

Hi-limit temperature

switch

Normally closed, verify operation:

Open: 269° to 291°F (132° to 144°C) .....

Closed: 173° to 207°F (78° to 97°C).......

Infinite.

Continuity.

Double thermal valve/

shut off valve

Verify gas supply is turned on at

regulator .................................................

Attached to pressure regulator at the

rear of the unit.

Gas ON red tab up (at regulator).

Gas OFF red tab down (at regulator).

Pressure regulator

Verify gas pressure (W.C.P.)..................

If on LP service verify proper gas

supply conversion.

5

"

Natural

10

"

LP/propane

Gas ON red tab up.

Gas OFF red tab down.

Convection assembly

Convection motor

Model JGS8850AD*

Measure voltage.....................................

Check motor windings to ground ............

120 VAC. (tolerance: 105 to 135 VAC)

No continuity.

RPM: Approx. 800 (tolerance: 600 to

1000 RMP).

Cooling fan motor

Measure voltage.....................................

Check motor windings to ground ............

120 VAC.

No continuity.

RPM: Idle: 3395.

Load:

3000.

Breakdown:

2400.

Venturi, right front, left

front, left rear burners

Shutter settings ...................................... Nominal: .038" (tolerance: .035" to

.041").

Venturi, right rear

burner

Shutter settings ...................................... Nominal: .038" (tolerance: .035" to

.041").

Electronic control

NOTE: To avoid

equipment damage,

use caution when

checking electronic

control circuitry

voltages.

L1 ...........................................................

Jumper ...................................................

Door logic sensor ...................................

Meat probe .............................................

Bake burner............................................

Broil burner.............................................

P26 (Black) to P5 (White): 120 VAC.

P18 to P23 (Black).

P4 (Red, pin 5) to P4 (Black, pin 2):

Door

Locked:

Continuity.

Door

Unlocked:

Infinity.

P2 (Red) to P2 (Red). See

"

Meat

Probe

"

chart.

P17 (Red) to P5 (White): 120 VAC.

P25 (Yellow) to P5 (White): 120 VAC.

Power cord 3-wire

Verify resistance of wires to terminals .... Continuity

Содержание JGS8750ADB

Страница 27: ... 2005 Maytag Services 16022089 A 1 Appendix A ...

Страница 33: ... 2005 Maytag Services 16022089 B 1 Appendix B ...

Страница 34: ...B 2 16022089 2005 Maytag Services Use Information ...

Страница 35: ... 2005 Maytag Services 16022089 B 3 Use Information ...

Страница 36: ...B 4 16022089 2005 Maytag Services Use Information ...

Страница 37: ... 2005 Maytag Services 16022089 B 5 Use Information ...

Страница 38: ...B 6 16022089 2005 Maytag Services Care Information ...

Страница 39: ... 2005 Maytag Services 16022089 B 7 Care Information ...

Страница 40: ...B 8 16022089 2005 Maytag Services Care Information ...

Страница 41: ... 2005 Maytag Services 16022089 C 1 Appendix C ...