12

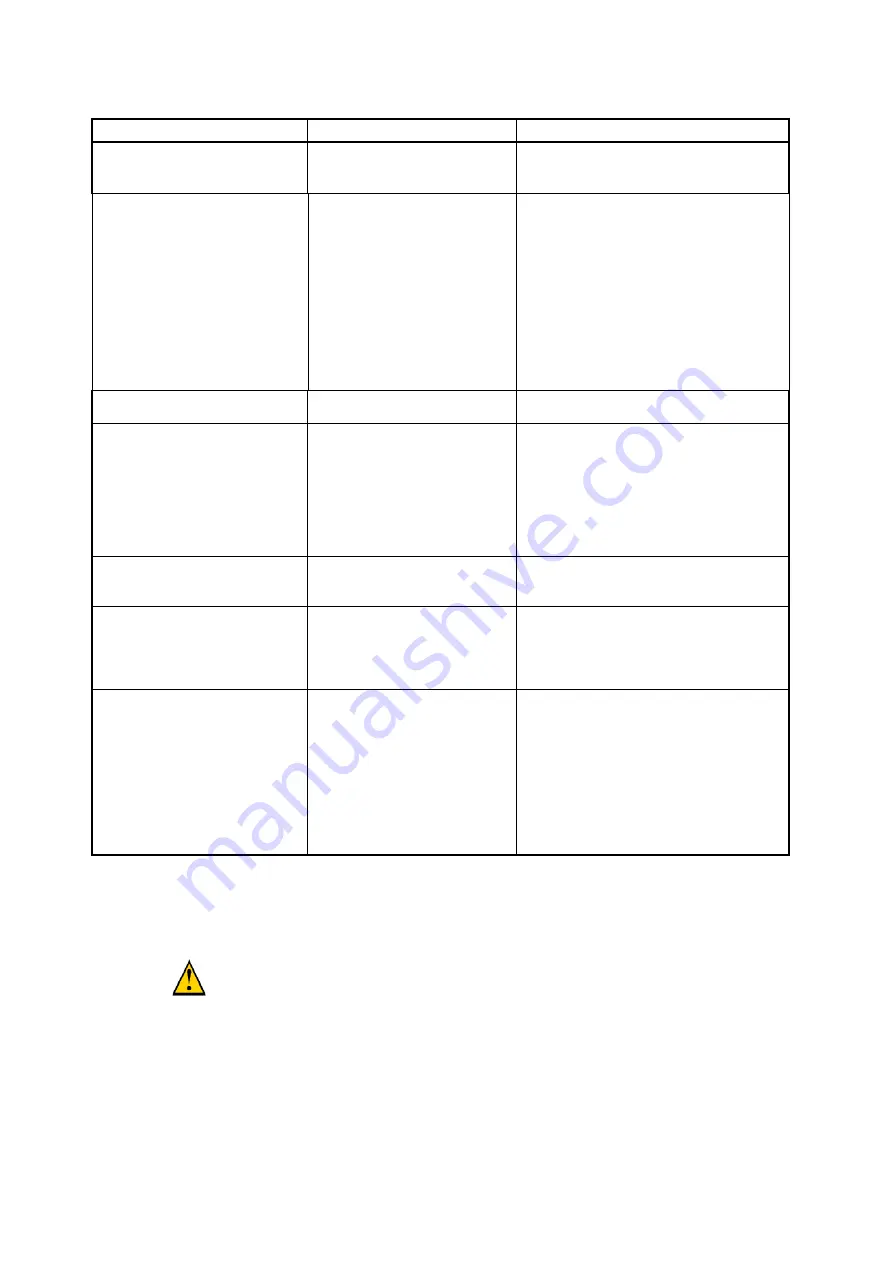

6.0 TROUBLESHOOTING

PROBLEM

CAUSE

ACTION

Unit will not start - compressor

does not start; no light in Power

Switch

•

Power Cord not attached

•

No voltage at receptacle /

incorrect voltage

•

Attach Power Cord

•

Verify voltage at Job Site

Compressor will not start

•

Circuit breaker has opened

•

Discharge pressure too high

•

HP Switch has opened

permanently

•

Insufficient pressure to close

LP switch (if fitted)

•

Electronics failure in Motor,

Bridge Rectifier or Filter

Capacitor / Relay

•

Identify cause of breaker activation,

rectify and reset

•

Reduce pressure and rotate V2 to Purge

and back to Recovery

•

Reduce pressure

•

Factory service required

•

Check connection, hoses, valves, gauges,

system may not contain refrigerant

•

Factory service required

•

Thermal cut-out has activated

•

Allow motor to cool. If still not working a

factory service is required

Compressor starts but cuts out

within a few minutes; pressure

indication on HP gauge is high

•

V2 is in Purge position and HP

switch activates

•

V3 not open and HP switch

activates

•

Recovery cylinder valve not

open

•

Blocked discharge hose

•

Air in system/cylinder

•

Rotate V2 to Recovery

•

Rotate V3 to open position

•

Open cylinder valve

•

Check & clear blockage

•

Bleed air from system/cylinder

Compressor stops intermittently

•

Vapour pressure of refrigerant

in cylinder is close to HP trip

point

•

Reduce cylinder temperature

Unit overheats

Excessive head pressure due to:

•

High ambient temperature

•

Restricted discharge hose

•

Air in recovery cylinder

•

Fan not turning

•

Reduce cylinder temperature

•

Check & clear restriction

•

Bleed air from cylinder

•

Factory service required

Recovery process too slow

•

Head pressure too high

•

System refrigerant iced up

•

Compressor seals are worn

•

Inlet filter blocked

•

Reduce cylinder temperature or change

cylinders

•

Throttle gauge manifold valves and V3 to

reduce pressure differential between LP

and HP gauges

•

Interrupt process to allow ice to dissipate

•

Replace compressor - check with

wholesaler for assistance

•

Remove filter and clean/replace cone

screen

7.0

SERVICE

7.0.1 The EVO-OS uses only UL, CSA or TUV recognized electrical components or

components that have been specially designed for this application.

7.0.2

DO NOT CHANGE any of these components as the safety of the machine could be

compromised. All service work must be performed at a Javac approved facility in order

to maintain the safety rating and the Warranty, if applicable.

7.0.3 Technical assistance and service information can be obtained by calling

UK (01642)-232-880 or the Organization where you purchased

the recovery machine

NOTE: Do not return a defective unit directly to the factory. Contact

your Wholesaler or the factory for assistance.