5

Installation

6. When control the welding machine with foot switch, the two-cores and three-cores plugs of foot switch

should be connected with the two-cores and three-cores sockets on the control panel of the welding

machine.

7. Connect the power cord with voltage-matched distribution chamber according to the input voltage grade of

welding machine. The connected voltage must be correct. The power voltage should varies in a permitted

range at the same time.

The welding machine can be operated after finishing the above installation operations.

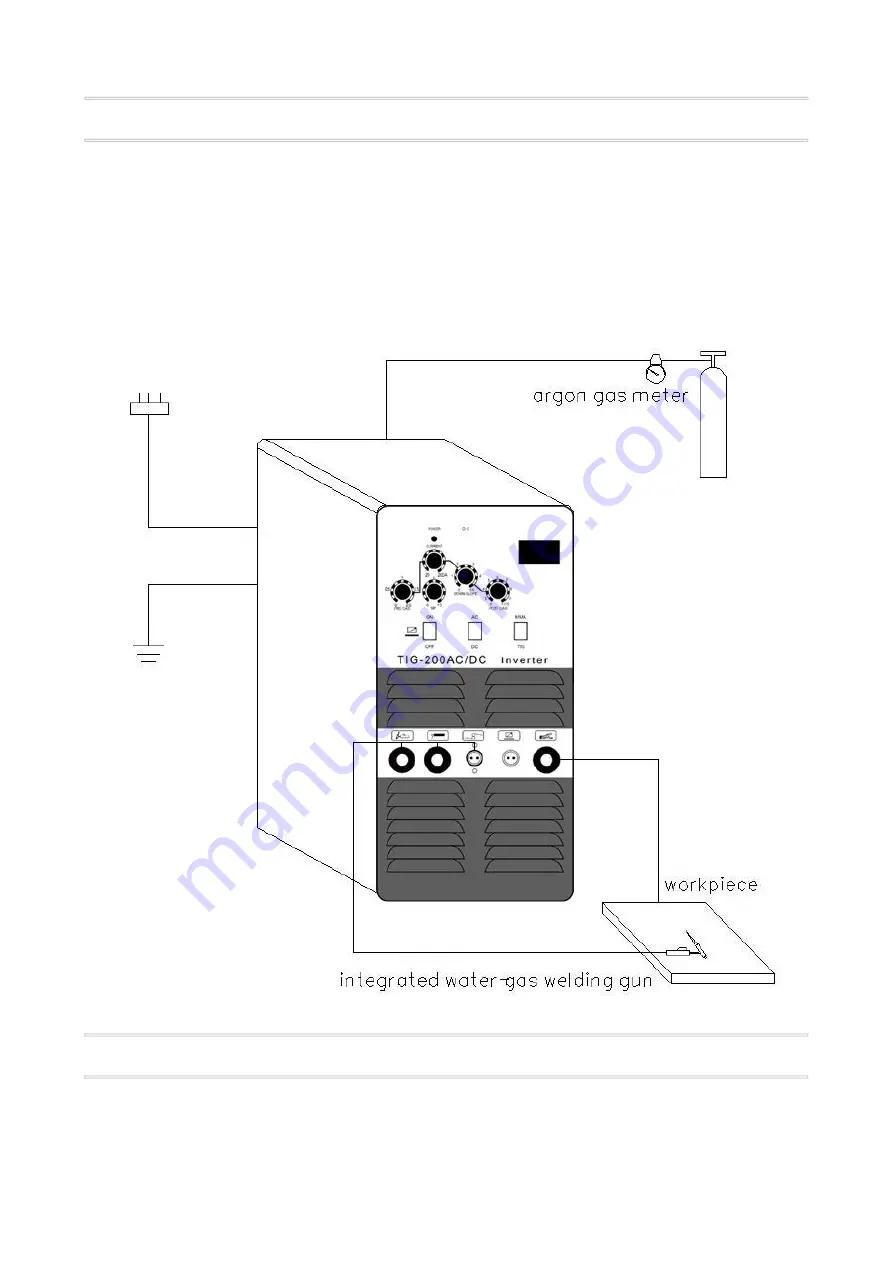

Sketch map for installation of AC.DC TIG-200 model

Installation

Application of AC argon arc welding

1.Locate the “AC/DC transfer switch” at “AC” position.

2.Turn on the power switch and the fan inside the machine start rotating.