installation and

operation instructions

Model SEC 180

page 12 of 16

JARVIS

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457–4926

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

6204012::.

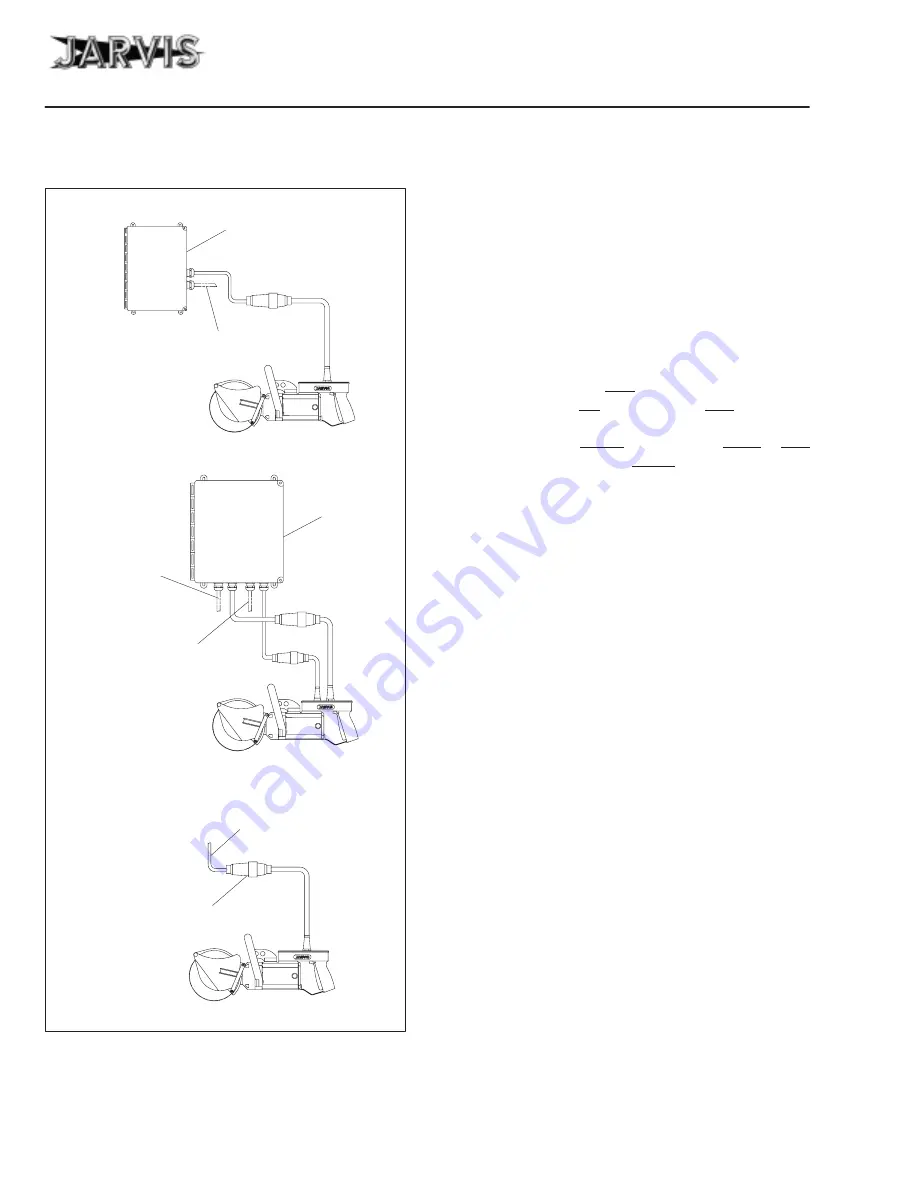

5 Plug the SEC 180 into the appropriate control box or

power supply outlet. See Figure 2 below as a guide.

Figure 2

Power Cord Supplied

by Customer

Control Box

SEC 180 Models with remote brake (single cord)

Power Cord

Supplied by Customer

Plug Connections

Supplied by Customer

Control Box

Power Cord

supplied by

Customer

SEC 180 Models with remote brake (dual cord)

and 42 V models

SEC 180 Models with internal brake (single cord)

Power Cord

for 42 V models

only. Supplied by

Customer

OPERATION INSTRUCTIONS

1 Plug in the SEC 180.

2 Each day, before you begin operation, perform the

following:

2.1 Make sure that the SEC 180 moves freely on the

balancer.

2.2 Make sure that the control handle or handles

work correctly. For single trigger tools: depress

the trigger and the tool should start. Release the

trigger and the tool should stop. For dual trigger

tools: depress each trigger separately and the

tool should not start; depress both triggers si-

multaneously (within one second of each other)

and the tool should start. Release either or both

triggers and the tool should stop. If the tool mal-

functions, remove it from service and report the

problem to your supervisor immediately.

Always operate the tool with both hands on the

handles. Continue to hold the tool with both

hands until the saw blade comes to a complete

stop.

2.3 Make sure that the electronic brake is working

correctly. Depress the trigger / triggers to start

the saw; release a trigger and the saw blade

should stop within 2.5 seconds. If the tool mal-

functions, remove it from service and report the

problem to your supervisor immediately.

3 Make the cut.

3.1 Position the SEC 180 saw.

3.2 Depress the trigger / triggers. Always use both

hands when operating the tool. Continue to

hold the tool with both hands until the saw

blade comes to a complete stop.

3.3 When the desired cut is achieved, release a trig-

ger. This will stop the blade.

3.4 Withdraw the SEC 180 from the carcass.

4 Unplug the SEC 180.