page 6 of 8

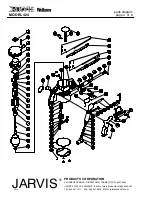

MODEL 424

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457-4926

UNITED STATES OF AMERICA E--MAIL.

TEL. 860-347-7271 FAX. 860-347-6978 WWW.

jarvisproducts.com

JARVIS

®

6205001

SPECIFICATIONS

Motor Power

1 hp

745 W

Operating Pressure

100 psi

6.9 bar

Air Consumption

28 ft

3

/ min

0.8 m

3

/ min

Blade Speed

7500 cuts / min

Stroke

1.125 in

29 mm

Control Handle

Single Trigger

Pneumatic

Blade Length

8 in

203 mm

16 in

406 mm

Overall Length (w/16 in blade) 31 in

787 mm

Weight (without blade)

8.2 lbs

3.7 kg

INSTALLATION INSTRUCTIONS

1 Suspend the Model 424 Wellsaw from a balancer.

Jarvis

part number 4042028 is available.

2 Make the necessary air connection.

2.1 The required compressed air supply is 28 ft

3

/

min at 100 psi. (0.8 m

3

/ min at 6.9 bars).

OPERATION INSTRUCTIONS

1 DAILY CHECKLIST:

1.1 Make sure that the compressed air supply is at

the correct pressure and that the lubricator is up

to the full mark. Use

Jarvis

Air Mist Lubricator

Oil

; if using a conventional air mist lubricator

set the feed rate at 8--10 drops per minute; if us-

ing a

micro fog

air mist lubricator set the feed

rate at 100 drops per minute.

Note:

Almost all

air mist lubricators are of the micro fog type

.

1.2 Make sure that the saw moves freely on the ba-

lancer.

1.3 Make sure that the saw is working correctly.

Depress

the trigger and the tool should start.

Release

the trigger and the tool should stop.

If

the tool malfunctions, remove it from service

and report the problem to your supervisor im-

mediately.

Always use two hands when starting and stop-

ping the saw. Continue holding the saw firmly

with both hands until the blade comes to a com-

plete stop

.

2 AVERAGE CUTTING AND RIPPING:

2.1 Place your work piece on a solid support at a

convenient working height.

2.2 Adjust the material so that the line of cut will be

close to the support. Secure it firmly.

2.3 To prevent starting torque of the motor from

pulling the saw away from line of cut, the opera-

tor should make a few short strokes until the

blade has cut into the material about 1/4 inch be-

fore squeezing trigger switch.

2.4

Both hands should be on the saw at all times

while cutting. Continue holding the tool with

both hands until the saw blade comes to a com-

plete stop.

2.5 The saw should be kept perpendicular to the

work piece while cutting material that is thicker

than one inch.

2.6 The saw should be pushed firmly into the mate-

rial while cutting.

2.7 Do not allow the saw blade or the blade support

to leave the work piece while cutting.

2.8 Never allow the saw blade to float into the mate-

rial while cutting.

2.9 Never permit any part of the saw, except the

blade and the blade support, to contact the work

piece during the cut.

3 CUTTING LARGE CROSS SECTIONS:

3.1 Rocking the saw in the cut will speed up the cut-

ting action.

4 SINKING THE BLADE THROUGH A SUR-

FACE:

specifications, installation

and operation instructions