28

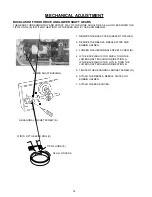

LOWER SHAFT SHIELD PLATE POSITION ADJUSTMENT

WHEN THE MACHINE IS SET FOR ZIGZAG STITCH, THE NEEDLE SHOULD START TO SWING 7.7 TO 8.7 mm

ABOVE THE SURFACE OF THE NEEDLE PLATE.

1 WHILE PRESSING THE NEEDLE UP/DOWN AND

LOCK STITCH BUTTONS, TURN THE POWER

SWITCH ON.

THE LCD SCREEN DISPLAY “FACTORY ADJUST”,

THEN ADJUSTING SCREEN WILL APPEAR.

TURN THE JOG DIAL TO SELECT “07. Phase Check”.

PRESS THE CONFIRM BUTTON (ENTER KEY).

2 TURN THE HANDWHEEL TOWARD YOU TO RAISE

THE NEEDLE AT 8.2 mm ABOVE THE SURFACE OF

THE NEEDLE PLATE.

3 REMOVE THE MACHINE BASE AND LOOSEN THE

SETSCREW (A) OF THE LOWER SHAFT SHIELD

PLATE. TURN SHIELD PLATE UNTIL THE SENSOR

SIGNAL CHANGES FROM “--”

q

TO “BM”

w

.

4 POSITION THE LOWER SHAFT SHIELD PLATE IN

THE CENTER OF SLIT OF THE LOWER SHAFT

SENSOR (SEE FIG. I).

TIGHTEN THE SETSCREW (A).

5 ATTACH THE MACHINE BASE.

MECHANICAL ADJUSTMENT

0.5–1.5mm

EVEN

LOWER SHAFT

SENSOR

LOWER SHAFT SHIELD PLATE

7.7 – 8.7 mm

PRESSER FOOT

NEEDLE #14

q

w

SETSCREW (A)

SENSOR (FEED)

SENSOR

(ZIGZAG AND

CUTTER)

FIG. I

LOWER SHAFT

JOG DIAL

CONFIRM BUTTON (ENTER KEY)

Содержание MC7700 QCP

Страница 1: ...SERVICE MANUAL PARTS LIST MC7700 QCP...