49

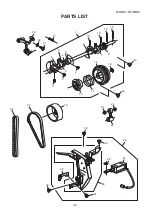

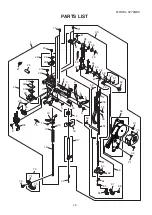

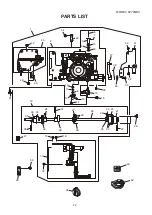

MODEL: 5270QDC

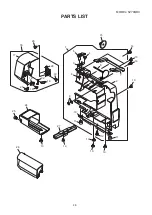

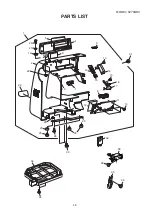

PARTS LIST

KEY PARTS

NO. NO.

DESCRIPTION

809605057

809030A04

808103002

809031B01

809032A04

809033A01

809036305

809501007

809037A05

000014306

809405066

809048001

000120203

809034A02

809035A03

809502008

812502101

808118000

735016307

000101828

000071013

000061205

809038008

735003002

000114802

000160102

639005003

000198604

101636A01

000081005

000115205

809039009

808059301

000149312

639080002

809188004

Front cover (unit)

Front cover

Front cover lid

Ornamental panel 1

Ornamental panel 2

Button 1

Slide volume

Touch panel (unit)

Touch panel sheet

Snap ring CS-3

Printed circuit board A (unit)

Flame retardant insulating paper

Setscrew 3x8 (B)

Button 2

Start/stop button

Printed circuit board F (unit)

Printed circuit board L (unit)

Lamp holder 2

Bobbin winder stopper

Setscrew 4x16

Washer 4

Nut 4-3-7

Arm sole front

Bed rubber cushion

Setscrew TP 4x12

Adjustable lock nut 4

Rubber foot

Setscrew 4x14 (B)

Emblem

Setscrew 4x8

Setscrew TP 4x6

Cap

Bed cover

Setscrew 3x8

Front cover set plate

Arm thread guide

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Содержание 5270QDC

Страница 1: ...First Edition 06 March 2020 SERVICE MANUAL PARTS LIST MODEL 5270QDC For Europe only...

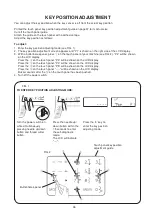

Страница 39: ...37 TOUCH PANEL KEY POSITION ADJUSTMENT GUIDE Print this illustration guide to its actual size...

Страница 52: ...50 MODEL 5270QDC PARTS LIST 1 2 3 4 6 5 7 8 9 10 11 12 13 14 17 15 18 19 20 9 21 21 22 23 16...