MODEL 3128

12

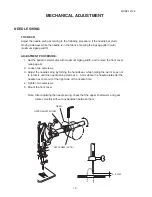

MECHANICAL ADJUSTMENT

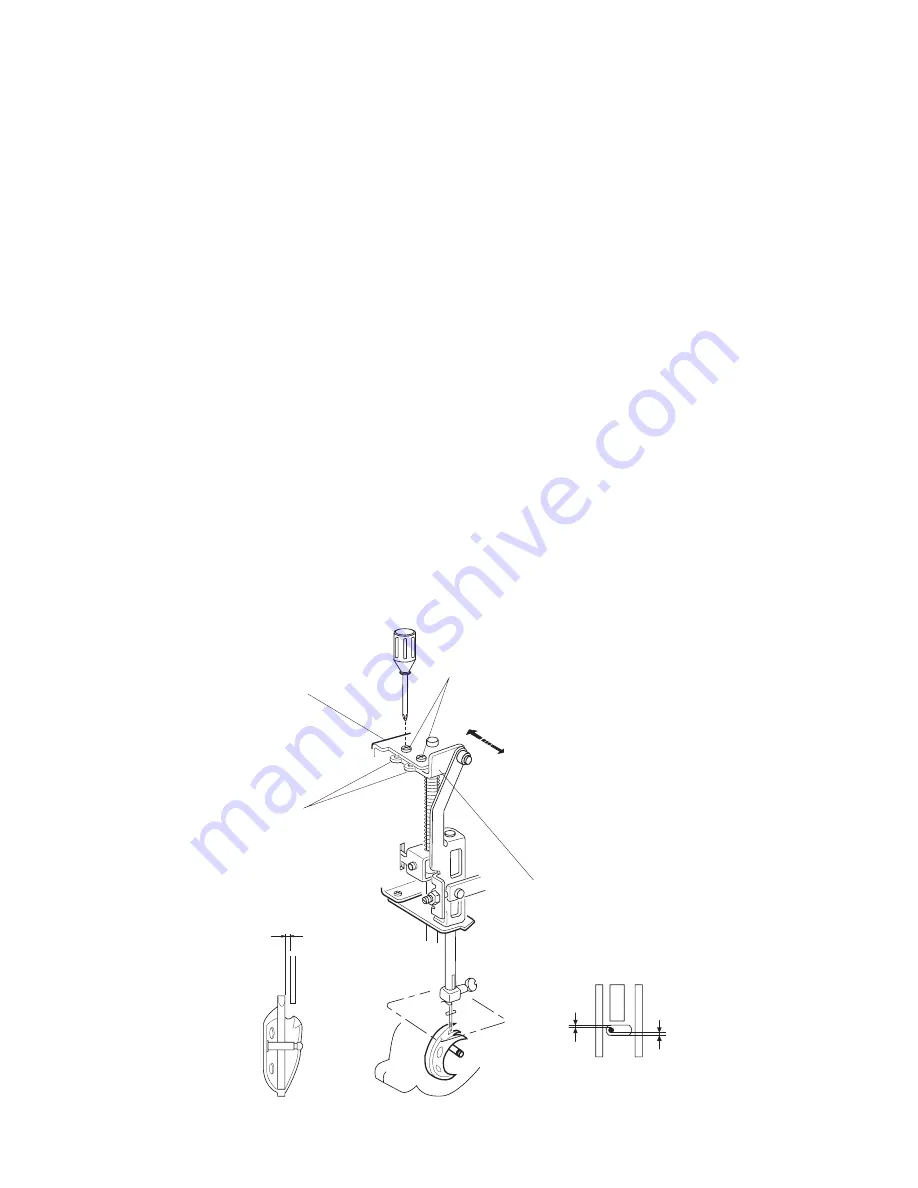

CLEARANCE BETWEEN NEEDLE AND

NEEDLE PLATE IS 0.15 MM OR MORE.

FIGURE "D"

-0.05 - 0.10 MM

PROJECTIONS

(2 SPOTS)

BASE PLATE

SETSCREW "A" (2 PCS.)

DIRECTION "B"

NEEDLE BAR SUPPORTER

ADJUSTING PLATE

CLEARANCE BETWEEN NEEDLE AND HOOK (NO.1)

TO CHECK:

The clearance between needle and shuttle hook should be -0.05 - 0.10 mm.

If not, make an adjustment as follows:

ADJUSTMENT PROCEDURE:

1. Remove the face cover (see page 4).

2. Set the pattern selector dial at maximum zigzag width, and turn the handwheel toward you to bring

the needle at left needle position.

3. Loosen 2 setscrews, slide the needle bar supporter adjusting plate in the direction of arrow as

shown below, and adjust the clearance between needle and shuttle hook to 0 - 0.15 mm tighten

setscrews.

* If the clearance is too large (more than 0.1 mm), slide the needle bar supporter adjusting plate in

the direction of

"

B

"

.

* If the clearance is too small (less than 0 mm), slide the needle bar supporter adjusting plate in the

direction of

"

C

"

.

Note: When adjusting the clearance, be sure to slide the needle bar supporter adjusting plate while

guiding the two projections along the edge of the base plate.

Note: Clearance between needle and needle plate is 0.15 mm or more as shown in figure

"

D

"

. If not,

adjust the clearance between needl and shuttle hook by using method of adjustment No.2 in

page 13. After readjustment, check if the clearance between needle and needle plate is 0.15

mm or more.

4. Attach the face plate.

DIRECTION "C"