Page 12

WATERPIK TECHNOLOGIES INC.

20. Connect the white wire labeled PS to the pressure

switch and the other white wire to its original

location on the Fireman's switch.

21. Reinstall the drain plugs and tighten securely.

Replace jacket/plug grommets.

22. Install the flue collector assembly. Be sure the

front and rear panels of the flue collector are

installed into the grooves on the front and rear

combustion chamber heat shield panels. Be sure

the sheet metal panels are not pinching any wires.

23. Attach the flue collector hold down clamps to the

clips located under the two center header bolts.

24. Replace the gap closures and tighten the screws

securely.

25. Double-check to make sure the wiring is not

pinched against sharp edges, or resting on the flue

collector assembly.

26. Reinstall rainshield assembly.

27. Replace the top assembly. Make sure the tabs are

outside the heater jacket. Fasten the top assembly

with the hex-head screws.

28. Install plastic tie wraps on wiring in the vestibule

(controls compartment).

29. Install heater door.

30. Reinstall the vent cap or drafthood, if one was

removed.

2G-3. Check Valve Installation

Install a check valve if there is any chance of back-

siphoning when the pump stops. Do not install any other

valve in the piping between the heater outlet and the

pool, unless it is being used as a diverter valve.

2G-4. Chlorinators, Ozone Generators,

and Sanitizing Chemicals

The Waterpik Laars Lite 2 heater is manufac-

tured with materials that are not compatible with high

concentrations of ozone, chlorine, bromine, or other

sanitizing chemicals. Heater damage caused by exces-

sive chemicals or improper ozonization is not covered

by the Waterpik Laars warranty. Be sure to adhere to

the following:

When ozone is injected upstream of the heater,

install an offgas mixing chamber, or an ozone

bypass system between the heater and the ozone

injector to prevent ozone and air from entering

the heater.

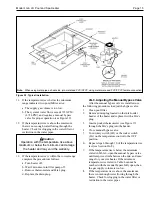

13. Lift the heat exchanger assembly out of the

heater. Reinstall heat exchanger 180 degrees

(inlet/outlet header left) from it's original posi-

tion.

14. After replacing the heat exchanger into the heater,

the end baffles must be replaced. Each one is

held in place by two screws which mount to the

top of the combustion chamber wall. Reinstall the

baffles on the front and rear of the heat exchanger

before continuing with the "Reversible Water

Connections" procedure.

15. Remove pressure switch retainer (plastic cable

clamp) from the inner panel (allow pressure

switch to float).

16. On U.S. models reroute pressure switch tube and

thermostat bulb assembly through hole in left side

of vestibule cover in reverse order. Canadian

models have no cover on the left side of the

vestibule. Relocate the pressure switch tube and

temperature sensor through the open side of the

vestibule.

17. Reinstall the temperature sensing bulb in the

header, and fasten it with the retainer bracket and

screw.

18. Reinstall the compression fitting at end of pres-

sure switch tube into inlet/outlet header and

tighten the fitting.

19. Route the white wiring from the high limit

switches beside the heat exchanger and down to

the original location following the pressure switch

tubing. Secure white wires to the pressure switch

tube with plastic wire ties.

Figure 16. Heat exchanger and end baffles.

Combustion

Chamber Wall

Heat Exchanger

End Baffles

Heat Exchanger

Содержание LD

Страница 27: ...Model LG LD Pool and Spa Heater Page 25 NOTES...