Issue: 01.06.2023

Page 7

Example for Suction Pipe Selection:

Cellar Plus 70-S3, outdoor unit mounted above indoor unit with vertical riser 4.5m and horizontal pipe run 7.4m, the suction line

¾”

OD is composed of 5pcs elbow 90

0

long radius and 1pcs 180

0

std radius.

Read equivalent length from

Table 7

.

•

Elbow 90

0

long radius; 5 x 0.4 = 2.0m

•

Elbow 180

0

std radius; 1 x 1.0 = 1.0m

•

Total pipe run = 7.4 + 4.5 = 11.9m

Total equivalent length = 2.0 +1.0 +11.9 = 14.9m

Read from

Table 6

,

With total equivalent length 14.9m, the horizontal suction pipe selected based on column 20m, which is

7/8”

OD to minimize the

capacity drop.

In this example, if the outdoor unit is installed

above

the indoor (this is the most severe condition for oil return especially at low

ambient and low room temperature). Suction riser must be selected based on column 10m,

which is ¾” OD to ensure sufficient

gas velocity to return oil to compressor.

Note: If the outdoor unit installed below the indoor unit, the vertical pipe size follows the size of the horizontal pipe.

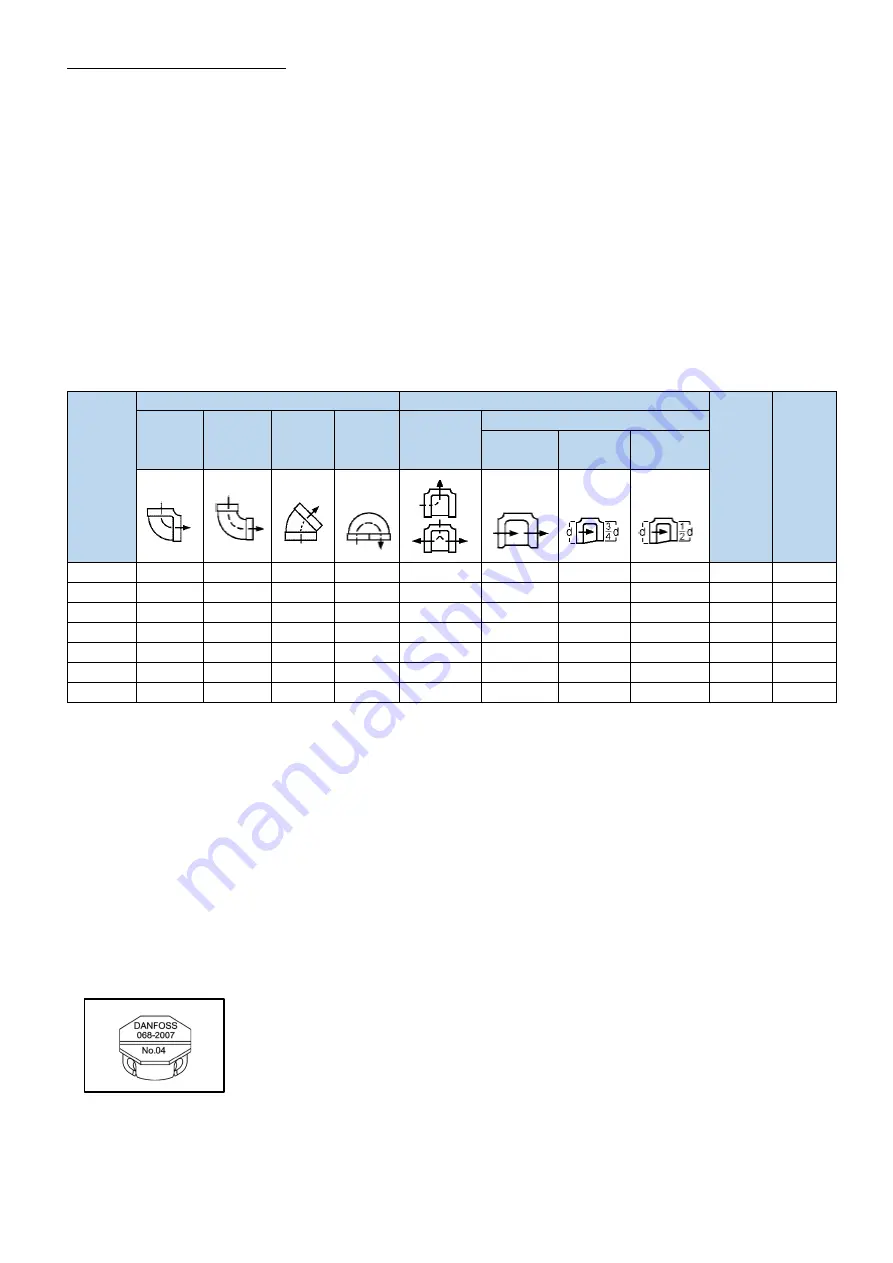

Table 7: Equivalent Length for Fittings and Valve (in meter)

Expansion Valve

•

All evaporator models are pre-fitted with expansion

valve TE2-02 in the piping, except JCC2-80EV which is

supplied with two sizes of orifice as standard. Orifice

size -03 is installed in the piping, and the orifice size -

04 was supplied loose (packed in a polybag tagged

to the expansion valve body).

•

The capillary tube label, which is in green color

fastened around the capillary of expansion valve

indicates the pre-fit orifice size (Example:

Figure 8

indicates orifice size (04).

Figure 8: Capillary Tube Label

•

Refer

Table 6

to change the orifice size in JCC2-80EV

to match the coupled condensing unit. Follow

Figure 9

to install the orifice.

•

Installer is recommended to change the capillary tube

label accordingly if orifice had been changed.

•

Incorrect positioning of the sensing bulb will lead to the

malfunctioning of the expansion valve. Refer

Figure 10

for the correct sensing bulb orientation to suit different

pipe diameters.

•

Never mount the sensing bulb on the bottom side

of

the horizontal piping due to oil returning to the

compressor may give false signal to the expansion

valve.

•

It is recommended to mount the sensing bulb on the

horizontal pipe. If mount the sensing bulb at vertical

pipe, the capillary tube must be pointing upwards to

avoid malfunctioning of the expansion valve.

•

Make sure the sensing bulb is far from the brazing or

remove the sensing bulb before brazing.

No

Reduction

Reduced

25%

Reduced

50%

3/8

0.4

0.3

0.2

0.7

0.8

0.3

0.4

0.4

5.2

0.2

1/2

0.4

0.3

0.2

0.7

0.8

0.3

0.4

0.4

5.2

0.2

5/8

0.5

0.3

0.2

0.8

0.9

0.3

0.4

0.5

5.5

0.2

3/4

0.5

0.3

0.2

0.8

0.9

0.3

0.4

0.5

5.5

0.2

7/8

0.6

0.4

0.3

1.0

1.2

0.4

0.6

0.6

6.7

0.3

1 1/8

0.8

0.5

0.4

1.2

1.5

0.5

0.7

0.8

8.8

0.3

1 3/8

1.0

0.7

0.5

1.7

2.1

0.7

0.9

1.0

12

0.5

Straight Through Flow

Smooth Bend Tee Connections

Nominal

Pipe or

Tube Size

(inch)

Globe or

Solenoid

Valve

Gate

Valve

Smooth Elbows

90

0

Std

90

0

Long

Radius

45

0

Std

180

0

Std

Flow

Through

Branch

Содержание CellarPlus 70-S1/S3

Страница 1: ...CELLAR PLUS CELLAR COOLER RANGE ISSUE 01 06 2023 CELLAR COOLER RANGE TECHNICAL MANUAL R448A R449A ...

Страница 23: ...Issue 01 06 2023 Page 20 Figure 27 Wiring Diagram BSCU 30 M3 BSCU 35 M3 Figure 28 Wiring Diagram BSCU 40 M3 ...

Страница 26: ...Issue 01 06 2023 Page 23 Figure 30 Declaration of Conformity Outdoor ...

Страница 27: ...Issue 01 06 2023 Page 24 Figure 31 Declaration of Incorporation Indoor ...

Страница 28: ...Issue 01 06 2023 Page 25 Figure 32 Declaration of Incorporation Outdoor ...

Страница 29: ...Issue 01 06 2023 Page 26 Figure 33 EU Declaration of Conformity Outdoor ...

Страница 30: ...Issue 01 06 2023 Page 27 Figure 34 EU Declaration of Incorporation Indoor ...

Страница 31: ...Issue 01 06 2023 Page 28 Figure 35 EU Declaration of Incorporation Outdoor ...