12

Put the items in a separate container. Use ultrasonic waves to

penetrate the container to do the cleaning.

Suitable Locations:

medical instrument sterilisation rooms,

precision electrical parts manufacturers, watch and precision

parts manufacturers, mobile phone and electronics service

shops, large printing shops.

Different industries use different fluids inside the container:

1. Watch service shops - Watch oil (to prevent rust)

2. Medical instrument sterilisation – Special solution

(cleaning prior to sterilization)

3. Precision electrical parts – Hexane (to dissolve grease, to

evaporate quickly)

4. Mobile phone and electronic service shops - Pure alcohol

(to evaporate quickly).

5. Printing shops – Acetone are often used (to dissolve ink)

6. Homes - Rubbing alcohol (to remove odor, to clean and to disinfect at the same time).

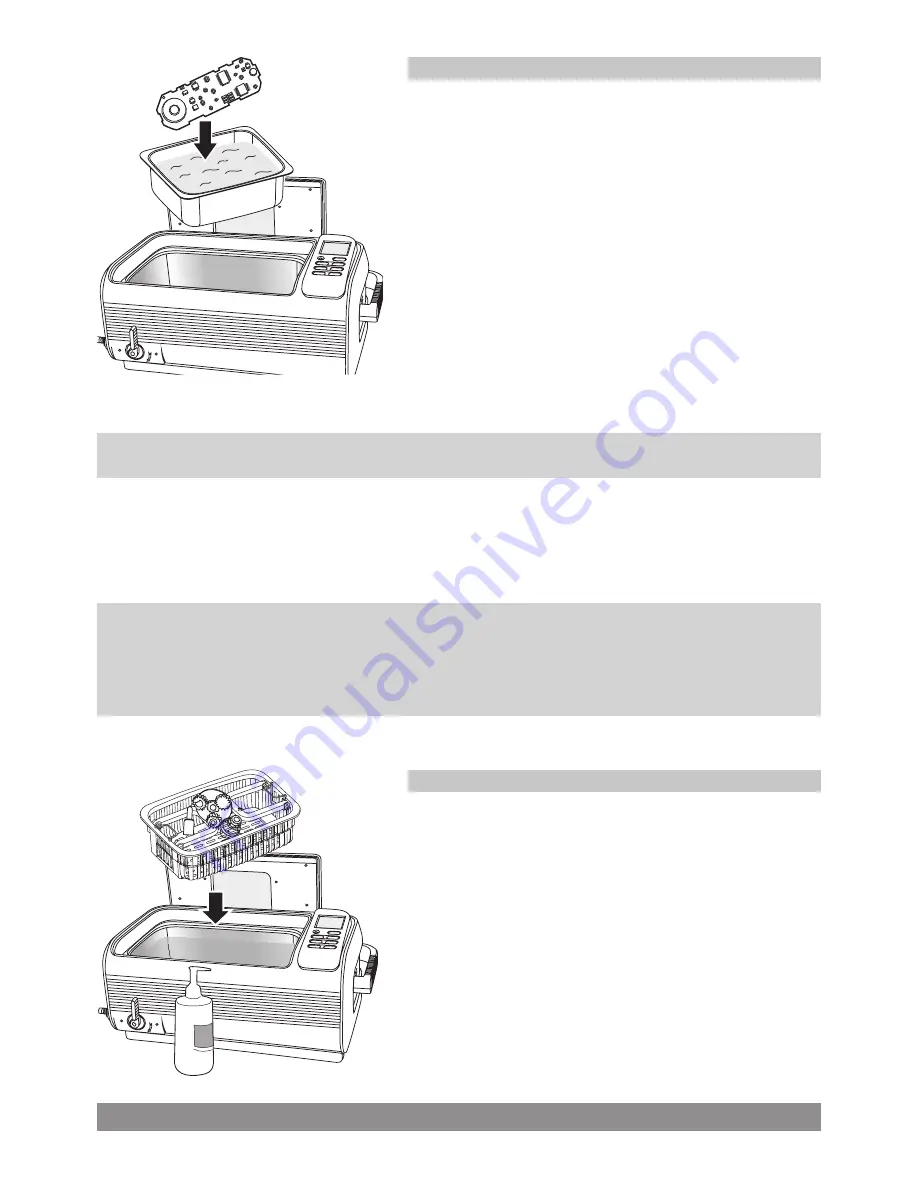

Cleaning Method:

1. Put the item inside a container. Add proper fluid to submerge the area to be cleaned.

2. Place the container in the tank directly. Add water to a level between “MIN” and “MAX”, do not overflow.

3. Turn the power switch on. Press Time button to set the timer to 10 minutes. Press On/Off button to start

cleaning. Ultrasonic waves will penetrate the container and clean the items.

NOTE:

Optional stainless steel indirect cleaning tank is available with this model.

Debris accumulated over a long period of time, greasy or

heavily soiled.

Suitable Locations:

metal processing and jewellery makers,

hardware manufacturers, shooting clubs, homes, golf clubs,

automotive repair shops.

Cleaning Method:

1. Large items can be put in the tank directly. Small items can

be put in the basket then put in the tank. Do not put the items

on top of each other to avoid rubbing during cleaning.

2. Add water to a level between “MIN” and “MAX” and above

the area to be cleaned.

3. Add 50 ml (3 tablespoons) of dishwashing liquid.

INDIRECT CLEANING

Selection of container:

1. Plastic containers – Plastics are soft and will absorb about 30% of ultrasound energy and reduce the

cleaning effect.

2. Aluminum containers – Absorbs about 20% of ultrasonic energy.

3. Stainless steel containers – Absorbs about 8% of ultrasonic energy.

Avoid acetone from contacting the plastic housing to prevent corrosion. Use Indirect Cleaning

and a glass or metal container for acetone.

ENHANCED CLEANING

Содержание ULTRA 9020

Страница 10: ...8 PRODUCT EXPLODED VIEW...