ENGLISH

17

Jacuzzi Whirlpool Bath DE99000A 3/06

Drain Overflow (supplied)

A drain/overflow assembly must be installed on the bath,

water tested, and connected to the sanitary system of the house.

After opening the carton, inspect for damage or missing parts.

NOTE: The overflow fitting (supplied) of the drain/over-

flow assembly MUST be installed before the wood frame

or (for undermount tubs) the counter is installed.

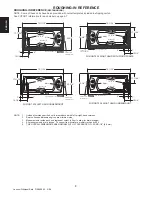

Overflow Fitting Installation

Remove and open the overflow fitting from the drain kit

(supplied). Remove washers and nuts from the overflow fit-

ting.

Place a small bead of plumbers putty, silicone, or similar

approved sealant around the underside of the top flange.

Place the overflow fitting into the overflow hole of the tub.

From the underside of the unit, place the rubber washer

then locknut on the fitting and tighten securely. Be careful

not to over tighten.

The overflow fitting accepts 1-1/2" (38 mm) slip joint type

drain line connections. Assemble in accordance with local

plumbing or building codes.

After the drain is fully installed, test for proper drainage. If

the unit does not drain properly, rectify this condition before

proceeding with the installation. Jacuzzi Whirlpool Bath is

not responsible for removal and or reinstallation costs.

NOTE: Watertight installation of the drain is the installer's

responsibility. Drain leakage is excluded from the Jacuzzi

Whirlpool Bath warranty of this product.

Plumbing and Water Supply

Clean-Up After Installation

Acrylic Surfaces

To avoid dulling and scratching the acrylic surface of the bath, never use abrasive cleaners. A mild liquid detergent and warm

water will clean soiled surfaces.

Remove spilled plaster with a wood or plastic edge. Metal tools will scratch the surface. Spots left by plaster or grout can be

removed if lightly rubbed with detergent on a damp cloth or sponge.

CAUTION: Use of chemicals and/or chemical cleaners may be hazardous to your health.

Paint, tar, or other difficult surface stains can be removed with paint thinner, turpentine, or isopropyl alcohol (rubbing alcohol).

NOTE: use these chemicals only on ACRYLIC SURFACE stains.

Minor scratches which do not penetrate the color finish can be removed by lightly sanding with 600-grit wet/dry sandpaper.

You can restore the glossy finish to the acrylic surface of the bath with a special compound, Meguiar's #10 Mirror Glaze. If that

is not available, use automotive rubbing compound followed by an application of automotive paste wax.

Major scratches and gouges which penetrate the acrylic surface will require refinishing. Ask your Jacuzzi Whirlpool Bath

dealer for special instructions or visit our web site at

http://www.jacuzzi.com/

. To find service agent listings for:

Electrical or Mechanical Repairs visit

http://jacuzzi.com/pdf/ASA.PDF

Finish, Surface, or Shell-Related Repairs visit

http://jacuzzi.com/pdf/AFC.PDF

Repair Parts or Accessories visit

http://jacuzzi.com/pdf/MPD.PDF

Wood Surfaces

Cleaning

Your teak/wenge wood is dissolved by strong or corrosive cleaners, so always use the mildest cleaner. NOTE: DO NOT

USE HARSH CLEANERS ON WOOD SURFACES.

CAUTION: Use of chemicals and/or chemical cleaners may be hazardous to your health.

A 75/25 mixture of liquid laundry detergent and chlorine bleach may be adequate. Apply this mixture with a stiff brush,

scrubbing lightly with the grain. Leave it on the wood for several minutes to give the detergent time to suspend the dirt and

the bleach time to lighten the wood, then rinse the wood thoroughly, brushing it to clear the grain. Allow to dry.

Plumbing

All Jacuzzi Whirlpool Bath products are factory tested for

proper operation and watertight connections prior to shipping.

If leaks are detected, notify your Jacuzzi Whirlpool Bath dealer.

Do not install the unit.

Water Supply

Consult local authorities for plumbing code requirements

in your area.

IMPORTANT: Proper installation of the fill spout plumb-

ing and compliance with local codes are the responsibil-

ity of the installer. Jacuzzi Whirlpool Bath does not war-

rant connections of water supply fittings and piping, fill

systems, or drain/overflow systems. Nor is it responsible

for damage to the bath which occurs during installation.

CAUTION: A nonflammable protective barrier must be

placed between soldering work and bath unit to prevent

damage to the bath.

Faucet Installation

NOTE: Selecting a faucet for rim mounting:

The combined thickness at the rim of the tub shell and the

wood trim is 2" (50,8 mm) nominal. The length of the

faucet tailpiece(s) must be long enough to extend past

this dimension and have ample clearance to assemble any

hardware (i.e. locknut, water supply fittings, etc.) neces-

sary for installation. For undermount units, the combined

thickness of the tub shell is 1/2" (12, 7 mm) nominal and

the undermount deck should not exceed the length of the

faucet tailpiece(s) including any assembly hardware.

Anti-Siphon Valve or Equivalent Backflow

Preventer

Optional backflow prevention installation. Anti-Siphon

valves or Equivalent Backflow Preventers are not supplied

with the tub. Consult your local plumbing code requirements

for the minimum height above the tub rim.

OVERFLOW

FITTING

PUTTY/SEALANT

(NOT PROVIDED)

FLAT RUBBER WASHER

LOCKNUT

TIGHT

LOOSE

SLIP JOINT WASHER/NUT