The JACKSON SAFETY

®

WH30 Albatross welding helmets are suitable, but not limited to the following applications:

AC/DC pulses

Inverters WIG/TIG

Stick welding

Argon/Helium

MIG/MAG

protective gas electrodes

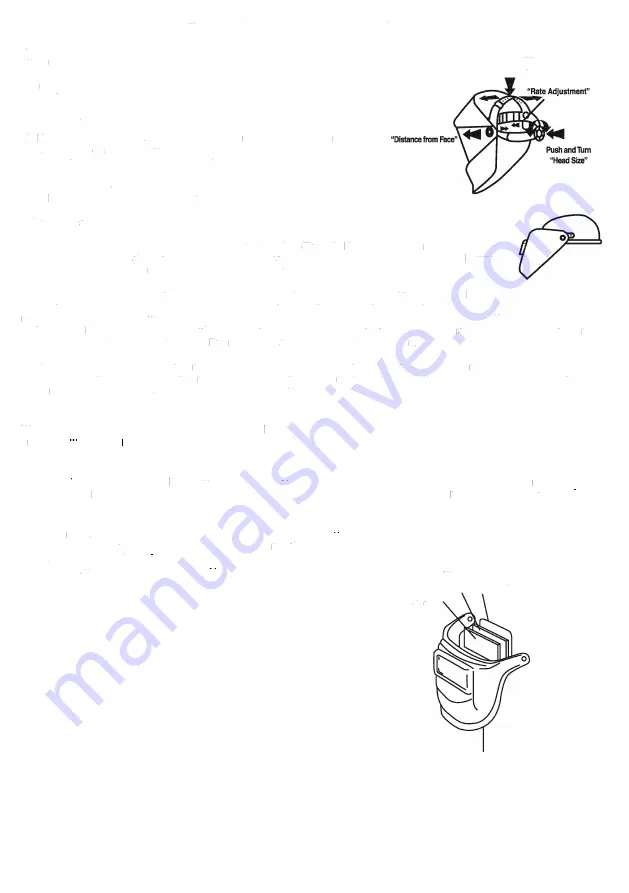

Preparation for Operation

JACKSON SAFETY

®

WH30 Albatross welding helmets are fully assembled and ready to

be used after minor adjustments. All welding helmets are equipped

with

a comfortable

headgear that can be adjusted in four different

ways:

• Push and move to adjust the "head height'

• "Rake adjustment" to limit the upper and lower helmet positioning

• Push and turn to adjust the "Head Size"

• Turn to adjust the "Distance from face"

lJm

Puah and move

"H11d Hiighl"

The JACKSON SAFETY

®

WH30 Albatross welding helmets for hard hat (Type: JACKSON SAFETY

®

Hard Hat, product

code J8500 to be sold separately) are equipped

with

a complete fastening mechanism. Fastening the mechanism by

way

of

pushing the pins into the holes provided in the attachment adaptor of the mounting device.

The JACKSON SAFETY

®

WH30 Albatross welding PAPR head tops are designed to

work

exclusively

with

the JACKSON SAFETY

®

AIRMAX

R60

PAPR Blower Unit and are equipped

with

a modified head gear that incorporates an air duct and connector and a face seal to deliver additional

respiratory protection during the welding related activities. Please follow the instructions for use supplied with the AIRMAX R60 PAPR blower unit

(JACKSON SAFETY

®

code J5200, sold separately) to connect the head top the air delivery system. Do not operate or enter the contaminated

area before reading and following these instructions. Failure to do so may lead to serious respiratory injury.

Before commencing work please inspect carefully the welding helmet and the passive glass for any visible marks, cracks, pitted or scratched surtaces;

damaged surfaces even on protection plates reduce vision impair protection. If protection plates are scratched, damaged or built up with spatter

please replace. When changing glass lens please use Protective Gloves.

We recommend you to use the welding helmet for a period of

1

0 years. The duration of use depends on various factors such as way of use, cleaning,

storage and maintenance. Frequent inspections and replacement in case of damage are recommended.

Service and Maintenance

Welding helmets should not be dropped. Do not place heavy objects or tools on or inside the helmet as they might damage the components. If used

properly the welding filter requires no further maintenance during its lifetime.

Cleaning

Clean the shield with mild soap and lukewarm water. Do not use solvents. The welding filter should be cleaned when changing the protection lenses.

This can be done by wiping it with a clean, dry piece of cloth or with a piece of smooth cloth moistened with pure alcohol or a commercial disinfectant.

Replacing the outer spatter lens and welding filter

Lift the flip front place helmet on its top. Remove the screws that hold the protective

lenses and welding filter replace the component(s) and make sure that you put

them back in the same order. Make sure that the

welding filter stays within outer and inner protective lenses.

Outer

Protection

Lena

Welding

Filter

lnntr Protection Lena

Shell

Содержание SureWerx WH30 ALBATROSS

Страница 1: ...WH30 ALBATROSS 0194 ...