19

07610-004-29-29-A

FAULT CODES

TROUBLESHOOTING

DISPLAY SHOWS

POSSIBLE CAUSES

REMEDY

“F1 Service needed,”

“No water in Booster”

1. Low or no water pressure.

2. Faulty inlet valve or fill relay.

3. Contactor to booster heater not turning off.

4. Faulty temperature input (P12) on IO

module.

5. Faulty temperature probe (T3).

6. Faulty float switch allows heaters to

operate with no water in tub.

1. Verify incoming water pressure is 8–12 PSI.

2. Verify that fill relay is supplying voltage to fill solenoid.

Replace faulty component.

3. Check for welded contacts. Verify that output from IO

module turns off when above the set temperature.

4. Substitute a 1.2 kΩ resistor for T3, and verify that booster

heater turns off. If not, replace IO module.

5. Verify that the booster-probe resistance is correct with

respect to temperature. (See Table 1.) If not, replace T3.

6. Replace float switch.

“F2 Service needed,”

“Check booster

thermostat”

1. Contactor to booster heater not turning off.

2. Faulty temperature input (P12) on IO module.

3. Faulty temperature probe (T3).

1. Check for welded contacts. Verify that output from IO

module turns off when above the set temperature.

2. Substitute a 1.2 kΩ resistor for T3, and verify that booster

heater turns off. If not, replace IO module.

3. Verify that the booster probe resistance is correct with

respect to temperature. (See Table 1.) If not, replace T3.

“F3 No water in wash

tank,” “Check inlet

water and door”

1. Malfunction of fill solenoid or fill relay.

2. Door is open, which inhibits fill mode.

3. Faulty door switch.

1. Replace faulty component.

2. Close door to activate door switch.

3. Replace or adjust door switch.

"F4 Service needed,"

"Check incoming

power"

1. Incoming power not properly connected.

2. L3 is missing (3-phase units only).

1. Check connections to heater.

2. Verify that L3 is present and connected properly.

“F5 Service needed,”

“Check booster thermo-

stat and high limit”

1. Faulty temperature input (P12) on IO

module.

2. Faulty temperature probe (T3).

3. Faulty high-limit switch.

4. Faulty booster heater.

5. Booster-heater contactor not energizing.

1. Substitute a 1.8 kΩ resistor for T3, and verify that booster

heater turns on. If not, replace IO module.

2. Verify that T3 resistance is consistent with Table 1. If not,

replace T3.

3. Replace high-limit switch.

4. Check booster heater for proper resistance. Replace if

incorrect.

5. Verify that drive voltage to contactor coil is present

during a call for heat and that contactor closes. If voltage is

present, replace contactor. If voltage is not present, check

wiring.

Содержание DynaTemp

Страница 2: ......

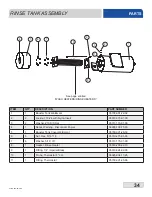

Страница 35: ...28 07610 004 29 29 A TUB ASSEMBLY PARTS 12 11 10 13 14 20 21 4 19 18 17 15 16 1 2 3 5 6 7 8 9 ...

Страница 37: ...30 07610 004 29 29 A STEAM TUB ASSEMBLY PARTS 12 11 14 20 21 4 19 18 17 16 1 2 3 5 7 8 9 6 13 15 10 ...

Страница 54: ...47 07610 004 29 29 A PARTS WASH RINSE ARM ASSEMBLIES 7 15 12 11 17 10 4 14 13 9 19 16 1 2 3 4 5 6 4 8 18 ...

Страница 63: ...56 07610 004 29 29 A DRAIN QUENCH OPTION SCHEMATICS ...

Страница 67: ......