Plasma 33 H

Operating Manual

Page 11

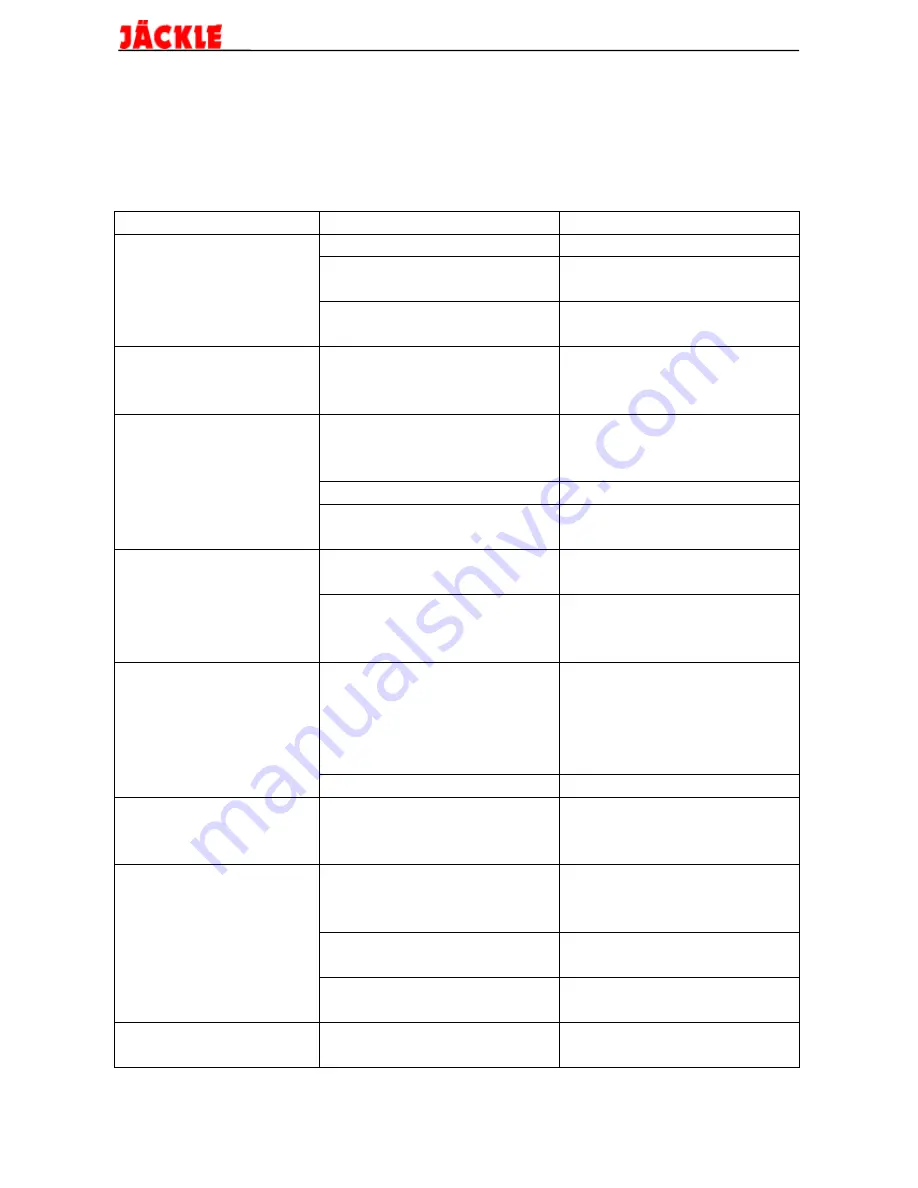

11. Trouble-Shooting

Warning!

Defects at the electrical unit may only be repaired by a specialist.

Trouble

Cause

Remedy

Mains connected and

mains fuse is faulty

check mains fuse

main switch turned

mains cable is

check mains cable

on / fan doesn't run

interrupted

fuse F1 at auxiliary

change fuse F1

transformer is faulty

(2 A slow / 250 V)

Fan is running /

light bulb is faulty

check / change light bulb

mains lamp does not

come on

No function when

parts at the torch head

check torch head

torch trigger is

are incompletely mounted

pushed, even the

(safety circuit)

contactor doesn't

torch trigger defective

check torch trigger

switch

torch trigger control

check torch trigger

lead interrupted

control lead

Malfunction lamp

insufficient pressure

remove shortage of

comes on when torch

air supply

compressed air

trigger is pushed

overheating of the

unit is ready for work

machine

again after ca. 5 minutes

if fan is running

Mains contactor

machine is running

check mains fuse

switches when torch

on 2 phases (mains

check mains leads

trigger is pushed,

fuse is faulty, one

but pilot arc

mains lead is

doesn't arise

interrupted)

torch parts defective

check / change torch parts

Pilot arc is

workpiece lead not

attach the workpiece clamp

burning / cutting

connected

to the workpiece

arc does not arise

Cutting arc is burning /

bad earthing contact

check / clean earthing

poor cutting quality

at the workpiece

contact (rust, paintwork,

or insufficient

oil, grease)

cutting power

insufficient pressure

check pressure air supply

air supply

plasma nozzle or

check / change plasma nozzle

electrode has burnt out

electrode

Cutting arc switches

cutting speed too

see chapter 7.2 Cutting

off

slow