INSTALLATION

The 37245-Series Quiet Flush Toilet is complete with a

dedicated PAR-MAX 4 pump to provide either sea or lake

water to rinse the toilet bowl when flushing the toilet. This

pump is intended to be located remotely from the toilet but

will function best if the distance from the toilet is kept to a

minimum. Because it is self-priming, it may be located

above the vessel’s waterline. It must be installed with the

Pumpgard strainer (provided with the toilet) located some-

where in the inlet plumbing to the pump. The toilet also

includes a multi-function flush control which should be

installed in a bulkhead location that is convenient to the toi-

let and allows access for wiring to run from the power

source and to both the toilet discharge pump and the

PAR-MAX rinse water pump.

Install the toilet seat and lid assembly on the china bowl

with the fasteners provided and position the toilet in its

desired location. When locating the toilet, ensure there is

adequate clearance above and to the rear of the bowl so

the seat and lid assembly can rotate slightly past vertical

so it will remain up when lifted. It is all right to rotate the

waste pump assembly under the china bowl to provide

clearance from possible obstructions, if desired. This can

be accomplished by removing the four white plastic hex

head caps from the nuts at the base of the china bowl and

removing the four machine screws and nuts that secure

the china bowl to the base. The base can then be

reattached to the bowl at any position in 90º increments.

Once the exact position for the toilet has been determined,

mark the location of the four base attachment holes on the

toilet mounting surface. Determine the best toilet attach-

ment method using 5/16

" (8 mm) fasteners (either ma-

chine screws for through bolting or lag screws for topside

attachment) and drill the appropriate size holes for the fas-

teners being used. If securing the toilet with lag screws into

a plywood underlayment below fiberglass, be sure to drill a

hole through just the fiberglass layer large enough to allow

clearance for the screw threads and shank to avoid

cracking the fiberglass.

The PAR-MAX pump should be mounted to a solid mounting

surface. It should be secured with four fasteners through

the rubber grommets that snap into the pump’s base. Do

not over-tighten the mounting screws and crush the grom-

mets such that they will not absorb vibration. The pump

may be mounted in any position; however, if mounting it to a

vertical surface it should be oriented so water dripping from

a loose port connection will not drip down on the motor.

Plumbing runs should be kept as short and straight as

possible. All plumbing should be completed with quality

3/4

" (19 mm) hose that will not collapse or kink. Route the

inlet hose from a 3/4

" (19 mm) through hull and seacock fit-

ting located well below the waterline (and well forward of

any discharge through hulls, if installed) to the pump inlet

port. Ensure the inlet hose passes through an accessible

location (preferably above the vessel’s waterline) that will

allow for the installation of the Toilet Pumpgard strainer

where it can be periodically inspected and cleaned of

debris. The Pumpgard strainer should be secured with two

fasteners to a solid mounting surface with the flow arrow

pointing towards the pump. The inlet hose should be cut and

each end attached to the strainer’s ports. The hose from

the strainer’s discharge port must connect with the PAR-MAX

pump’s inlet port. Provided with the toilet is a six foot length

of smooth white aesthetically pleasing hose to connect to

the back of the toilet bowl and be routed out of the head

area. Ideally, the PAR-MAX pump should be located so this

length of hose can be connected directly to the pump’s

discharge port avoiding an additional splice to the hose lead-

ing from the pump to the back of the toilet bowl. If this is not

practical, acquire a 3/4

" (19 mm) barb to barb hose mender

and splice the white hose to the supply hose from the dis-

charge port of the pump.

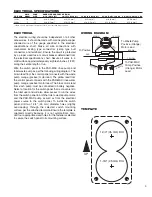

If the toilet is installed below the vessel’s waterline, in order

to prevent a siphon action from filling the toilet, a properly

positioned vented loop fitting must be installed between

the PAR-MAX pump and the back of the toilet bowl. The

vented loop fitting must be secured in a location that

remains at least 6-8 inches (15-20 cm) above the waterline

at all angles of heel and trim (see diagram).

The toilet discharge port is sized for 1

" (25 mm) hose. The

discharge hose should be a quality grade reinforced hose

suitable for waste applications. Route the discharge hose

to the holding tank in the most direct way with as few

bends as possible. To retain some water in the bowl, it is

best to loop the discharge hose up about 8-10 inches

(15-20 cm) as close to the toilet as practical then on to the

holding tank. It is best to avoid any dips or low spots in the

discharge plumbing that can act as water traps and collect

waste. If this occurs, waste can solidify and cause a

discharge blockage.

If the toilet is plumbed to an overboard discharge, and is

below the vessel’s waterline, the discharge plumbing must

include a properly positioned vented loop. The vented loop

fitting must be secured in a location that remains at least

6-8 inches (15-20 cm) above the waterline at all angles of

heel and trim. The maximum discharge head without a

notable decrease in pump performance is four feet (1.3 M).

Flood hazard. If toilet is installed below the

waterline, it must be installed with a properly

positioned vented loop in the discharge hose.

Failure to do so can result in flooding which

can cause loss of property and life.

WARNING

!

Waterline

Vented Loop

Heeled Waterline

2