JABLOTRON FUTURA

INSTALLATION MANUAL

25/43

JABLOTRON LIVING TECHNOLOGY

13

13 .

. Maintenance

Maintenance

The basic maintenance of the heat recovery unit consists of regular filter change and condensate drain checks. Regular filter change performed

once every 2 - 6 months (depending on the local outdoor air quality) is essential for correct and trouble-free operation of the heat recovery unit.

Check the condensate drain at least once a year and remove any dirt.

W e r e c o m m e n d t o c h e c k u n i t 's s u p p l y a n d e x h a u s t d u c t s (f a ç a d e b o x , g r i d , e t c .) a t l e a s t o n c e a y e a r (o r m o r e

W e r e c o m m e n d t o c h e c k u n i t 's s u p p l y a n d e x h a u s t d u c t s (f a ç a d e b o x , g r i d , e t c .) a t l e a s t o n c e a y e a r (o r m o r e

f r e q u e n t l y d e p e n d i n g o n t h e l o c a l o u t d o o r a i r q u a l i t y ).

f r e q u e n t l y d e p e n d i n g o n t h e l o c a l o u t d o o r a i r q u a l i t y ).

Pl e a s e m a k e s u r e t h a t t h e u n i t i s d i s c o n n e c t e d f r o m t h e e l e c t r i c a l m a i n s b e f o r e p r o c e e d i n g w i t h m a i n t e n a n c e .

Pl e a s e m a k e s u r e t h a t t h e u n i t i s d i s c o n n e c t e d f r o m t h e e l e c t r i c a l m a i n s b e f o r e p r o c e e d i n g w i t h m a i n t e n a n c e .

To meet the conditions of the f i v e - y e a r w a r r a n t y

f i v e - y e a r w a r r a n t y , it is necessary to perform a regular annual service inspection. During the inspection it is

important to perform the following tasks:

I n d iv id u a l t a s k s of s erv ice in s p ect ion a n d t h eir d es crip t ion

I n d iv id u a l t a s k s of s erv ice in s p ect ion a n d t h eir d es crip t ion

Functionality before the

inspection

- check that the unit is running and which mode is set

- turn the unit off from the control panel or via MyJABLOTRON application

- unplug from electrical mains

Heat exchanger status

- remove front cover (2 × screw)

- dismount filter plugs and remove them

- remove plugs A, B, C, D with a spatula of minimal width of 5 cm (2 in)

- check the heat exchanger visually

- clean first half of valve rails with clean, dry cloth

- plug in, wait for the valves to pass, unplug again

- clean second half of valve rails, plug in

- check operation of the actuators and movement of all valves to their end positions

- use vacuum cleaner to clean any remaining dust or dirt

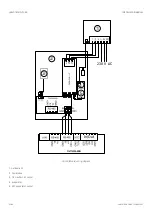

Inspection of wiring

- check tightness of contacts

- plug in

- check connection and operation of control panels

- check functionality of all buttons and other peripheries

Condensate drain

- clean the drain

- if necessary, optionally rinse with clean water and fill odor trap with water

Piping

- check that the façade box is clean

- check outdoor supply and exhaust pipes

- check connection of silencers to the unit and the distribution boxes

- check the connection of the flexi pipe to the distribution boxes

Filter clogging

- check filter clogging in %

- if necessary, change filters and run initialization

- offer the client to sell them annual supply of filters

Air flow regulation

- adjustment of control valves

- check the locking in the set position

- check settings of the distribution elements

- go through the settings with the client and in case he or she has any requirements for adjustments,

adjust the settings accordingly