24V

1.RUN

3.V-IN

2.DIR

4.ERR

5.PLS

0V

24V

1.RUN

3.V-IN

2.DIR

4.ERR

5.PLS

0V

(

1

)

(

1

)

(

1

)

(

1

) ~ (

2

)

(

2

)

(

2

) ~ (

3

)

(

3

)

(

3

) ~ (

5

)

(

3

) ~ (

5

)

(

6

)

(

6

)

(

6

)

(

7

)

(

7

) ~ (

8

)

(

8

)

(

9

)

(

1 0

)

(

1 0

)

Safety Instructions

Power

Before Operating the Product

Mounting

Wiring

Direction Setting

Functions

Operation Instruction

Speed Variation

Internal Speed Variation

External Speed Variation

Direction Setting

Acceleration and Deceleration

Error Signal Output

Motor Plus Signal Output

Error Status, Reset, History

Servo Brake

Troubleshooting

Dimension

Product specifications

1

.

2

.

3

.

3 - 1 .

3 - 2 .

3 - 3 .

4

.

5

.

5 - 1 .

5 - 1 - 1 .

5 - 1 - 2 .

5 - 2 .

5 - 3 .

6

.

7

.

8

.

9

.

1 0

.

11

.

1 2

.

Standard Accessories

INDEX

●

Power Connector (CN1)

●

Control Connector(CN2)

●

Mounting screws and nut

Screw

:

M4×15

Nut

:

M4

×

1

×

1

×

2

×

2

Power connector

(

CN-1

)

Control connector

(

CN-2

)

(

1

)

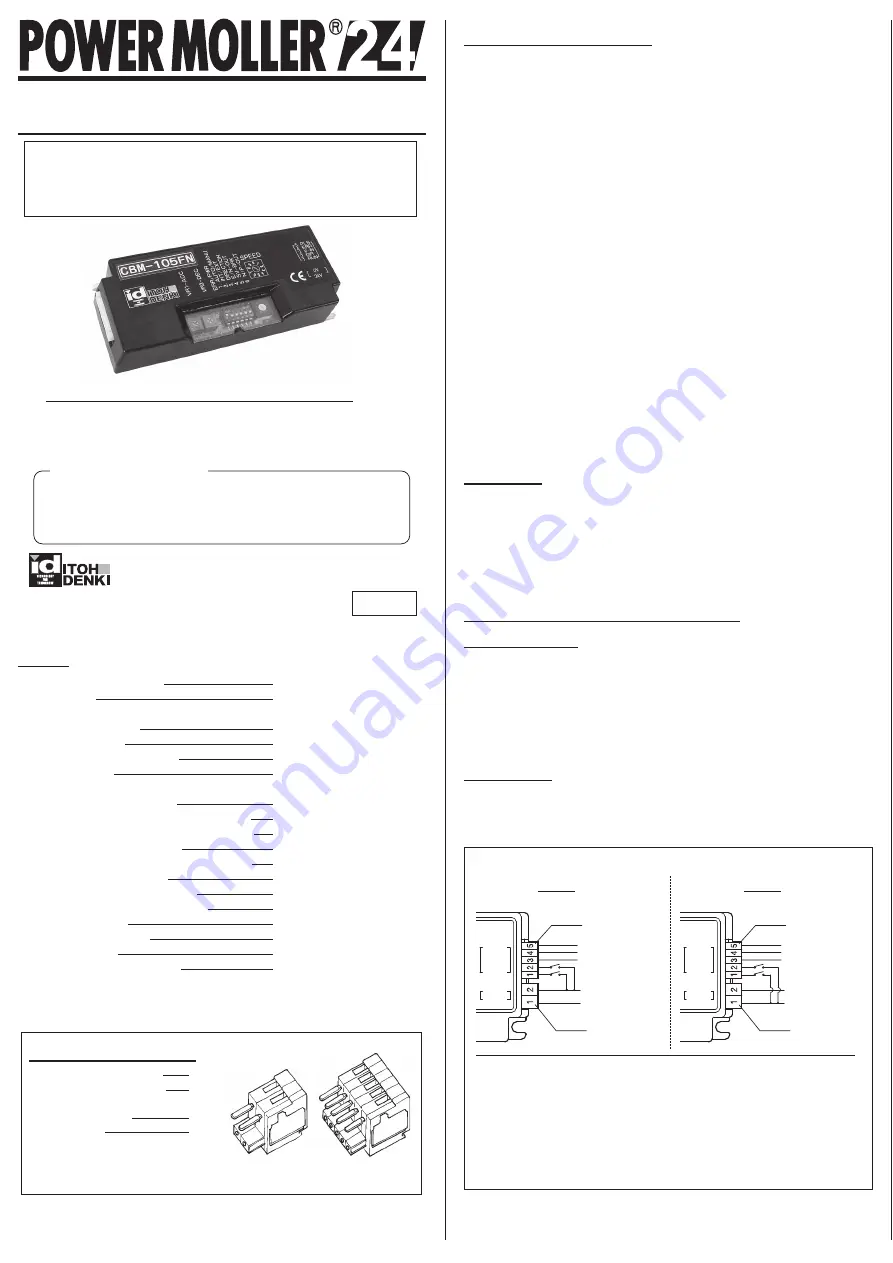

CN1

DC24V

0V

CW/CCW

RUN/STOP

0-10V IN

Error signal output

Motor pulse signal output

Error signal output

Motor pulse signal output

CN2

CN1

DC24V

0V

CW/CCW

RUN/STOP

0-10V IN

CN2

PM486FE , PM486FP , PM486FS , PM500FE

PM500FP , PM570FE , PM605FE , PMT42FE

*

BR(Brake) and LT(Low temperature) is not available on CBM-105

Thank you for purchasing a Itoh Denki CBM-105 series motor

driver.

Please read this manual before operating the product,

and keep this manual readily accessible for reference.

●

DC24V battery

●

Switching power (24VDC 5A) or smoothed and rectified power

●

Smoothed and rectified power (

≦

10% ripple)

※

Use stable power supply with 5A or over. The power supply should not be affected

by peak current 20A for 1msec.

NPN

PNP

Switch off the power, when removing from conveyor, wiring or maintenance is done,

otherwise you have a risk of electrical shock or injury

Respect the electrical regulations of the site or equipment, where the product in installed.

(Labor safety and sanitary regulations, electrical equipment technical standard, etc)

Operate the motor driver within its intended design and specifications to avoid electrical

shock, injury or fire.

Do not disassemble, repair nor modify the product (For which we do not warrant)

It might cause electrical shock, injury or failure.

Separately set the circuitry to monitor the important input and/or output signal status,

which might cause accident, because the signal may stay ON or OFF in case of the

CBM-105 driver card failure.

Be sure to shut off the power before inserting or removing any connector. Do not wire

connector left in the CBM-105 driver card.

Do not drop, give external impact nor pressure to the CBM-105 driver card. If that

happened, do not reuse it.

Make sure all the connectors are properly engaged with cables.

Make sure the conveyor frame and control box where the CBM-105 driver card is

mounted are grounded.

Do not switch ON or OFF the relay or contractor in close proximity to power or signal line,

or the CBM-10 driver card as the generated noise could cause malfunction.

Be sure to inject power or input signal for 15msec or over to ensure the proper reaction.

Do not remove any connector during operation. It may cause of damage to the driver card

or shorten its life time.

Do not shut power off during MDR is running. It may cause of damage to the driver card or

shorten its life time.

Do not get on the conveyor if power is ON to the driver cards. Do not turn on power, if

totes are not steady on conveyor. It might cause electrical shock, injury or failure.

Do not pull by force the Power Moller to turn.

It may cause of damage to driver card or shorten its life cycle.

Without power on to the driver card, dynamic brake or servo brake is not worked.

1. Safety Instructions

3. Before Operating the Product

3-1. Mounting

3-2. Wiring

2. Power

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

①

Make mounting holes in the conveyor frame to fit the fixing holes in the product.

(

See Dimensions in section 11

)

※

The product’s back place should be paid to prevent the metallic dust entry to

the product.

※

Make sure the conveyor us adequately grounded.

②

Fix the product tightly to the conveyor frame with the supplied mounting screws

and nuts with the recommended fastening torque between 1.5Nm and 1.9Nm.

・

Wiring should be made while the product is not powered.

・

Switch for Run/Stop or CW/CCW is an option and is not supplied.

・

Relay contact or PLC output is available instead of the above switch.

・

Wiring to the supplied connectors should be made before inserting into the driver.

-1 MDR run and stop

(

Mandatory

)

→

See section 5

-2 MDR direction (CW/CCW)

*

→

See section 5-2

*

Turning direction setting can also be done by dip switch on the PCB.

-3 External speed variation by analog voltage change

→

See section 5-1

*

Speed variation setting also can be done by Rotary Switch on the PCB.

-4 Discharge of error signal

→

See section 6

-5 Discharge of motor pulse

→

See section 7

【

Wiring diagram

】

CN2

Brushless DC Motor Driver

【

CBM-105 FN/FP

】

User Manual

Applicable Power Moller

(

MDR

)

models:

MDR (Motor Driven Roller)

MDR is DC brushless motorized roller for conveyor.

MDR is defined by Conveyor Equipment Manufacturers

Association (CEMA) and conveyor built by MDR is well

established technology in Material Handling Industry.

No.561

ITOH DENKI CO.,LTD.