5

Control Wires Installation

Step 1 – Route the valve control wires between the valves and the MC-E controller.

For wire runs up to 1000’ between the controller and the valves, it is recommended to use an 18 AWG

(1.0 mm

2

) multi-wire sprinkler valve connection cable. This cable is insulated for direct burial and is color

coded to simplify installation.

Step 2 – Attach one wire from each valve solenoid to

the white color-coded wire from the cable.

(Since the valve solenoid has no polarity, either

wire can be used for this connection.) Designate

this connection as the Valve Common.

Step 3 – Attach a separate cable wire to each of the

remaining valve solenoid wire. Take note of the

wire color being used for each valve as well

as the watering zone/area it is designated. This

information will be important when connecting

the valve wires to the controller’s station

terminals.

Step 4 – Use wire nut fasteners to secure the valve

solenoid wire connection. Waterproof all

connections with grease caps or similar

insulation method.

Step 5 – Route the other end of the control wires into the

provided conduit hole at the bottom of the cabinet. Leave about 8” of cable remaining in the cabinet. Expose

about 3/8” of bare wire from the station and the valve common wires.

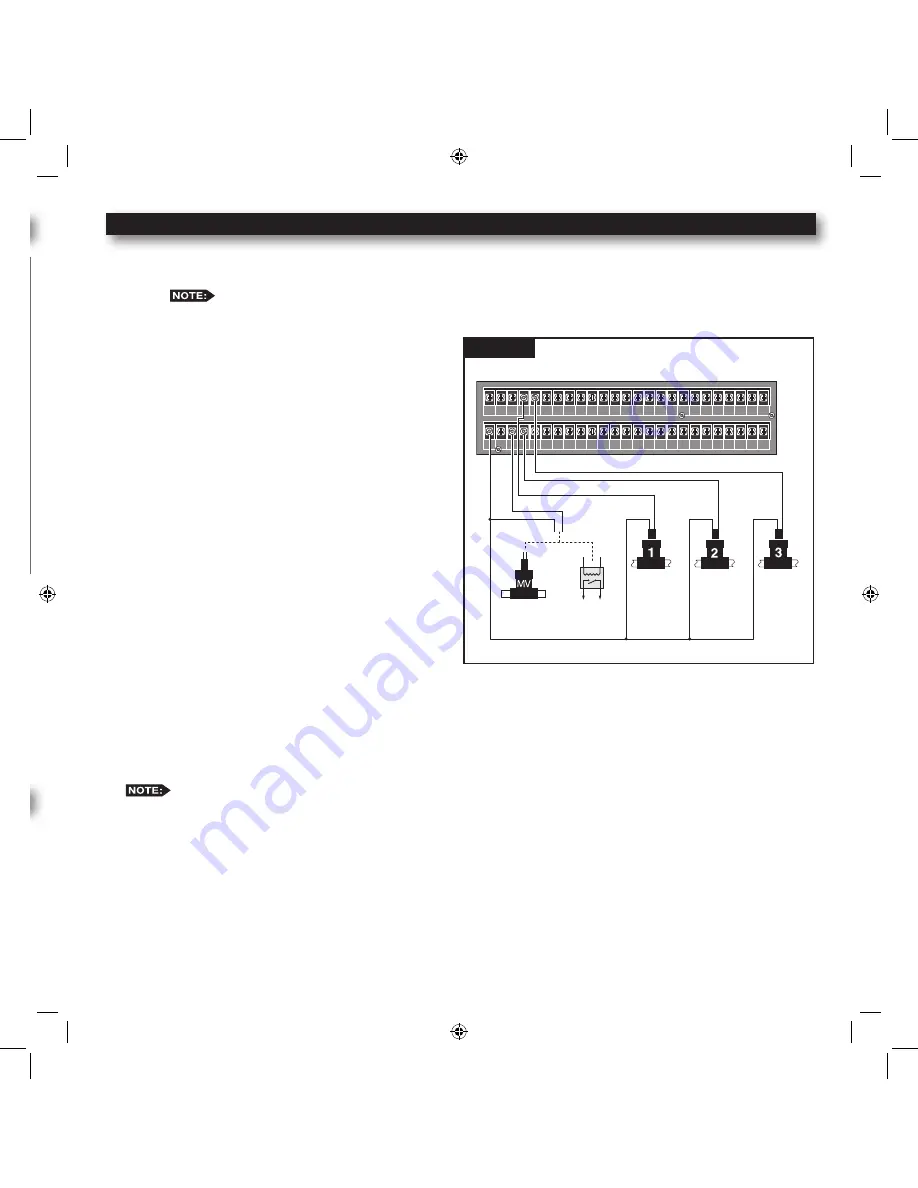

Step 6 – Secure the valve common wire to one of the three terminals labeled “VALVE COMMON” and each valve wire

to its appropriate station terminal designation.

*

For flow monitoring, with a flow sensor installed, Station #1 is programmed and used as activation circuit for

a normally-open master valve instead of a regular station valve. (See page 36 “Install Critical Flow Shut Off

Master Valve”.)

VALVE

COMMON

VALVE

COMMON

VALVE

COMMON

MASTER

VALVE

YEL RED

VALVE

COMMON

GND

1

3

5

7

9

11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41

2

4

6

8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42

Figure 2

Cabinet Installation

Step 1 – Selecting the proper installation site for the MC-E controller is

essential to safe and reliable operation. The controller features

a weather resistant cabinet designed for indoor and outdoor

installation. The controller should be installed on a vertical wall

or other sturdy structure near a grounded power source. Select a

location that provides as much protection from direct sunlight,

rain, snow and irrigation spray as possible.

Step 2 – Drive a wood screw (provided) into the wall at eye level.

(For Large Cabinet Unit - 18 Stations or more) Drive another

wood screw 8” (20.3 cm) directly below the first screw.

(For Small Cabinet Unit - 12 Stations or less) Drive another wood

screw 5 3/4” (14.5 cm) directly below the first screw.

Leave approximately 1/4” (6.5 mm) of the screw extended from

the wall to accommodate the cabinet.

For drywall and masonry installation, use proper screw

anchors to prevent the screws from loosening.

Step 3 – Place the controller cabinet on the screws using the keyhole slots on the back panel. Ensure that the cabinet is

installed securely on the screws. See Figure 1.

Step 4 – Open the controller door and remove the bottom panel door. Locate the bottom screw and tighten it securely.

The MC-E series has two available lockable, weather and vandal resistant steel pedestals for free standing applications.

For MC-E controllers with 12 stations or less, use the Irritrol P-2B pedestal. For MC-E controllers with 18 stations or

more, use the Irritrol P-6B pedestal. Follow the installation and mounting instructions that are provided with the pedestal.

Electrical Conduit Installation

Electrical conduit and adapters are not supplied with the controller but may be required for installations in your area.

Check with your local electrical codes and install conduit according to requirements.

For power wires, install a 1/2” (13 mm) NPT threaded conduit access body to the transformer assembly threaded nipple.

From the access body, install conduit to the power source.

For station valve wiring, install a 2” (5 cm) conduit adapter and conduit.

Master

Valve

Pump Start

Relay

Station 1

*

Station 2 Station 3

*

Wiring for standard (non-flow sensing) system