3-13

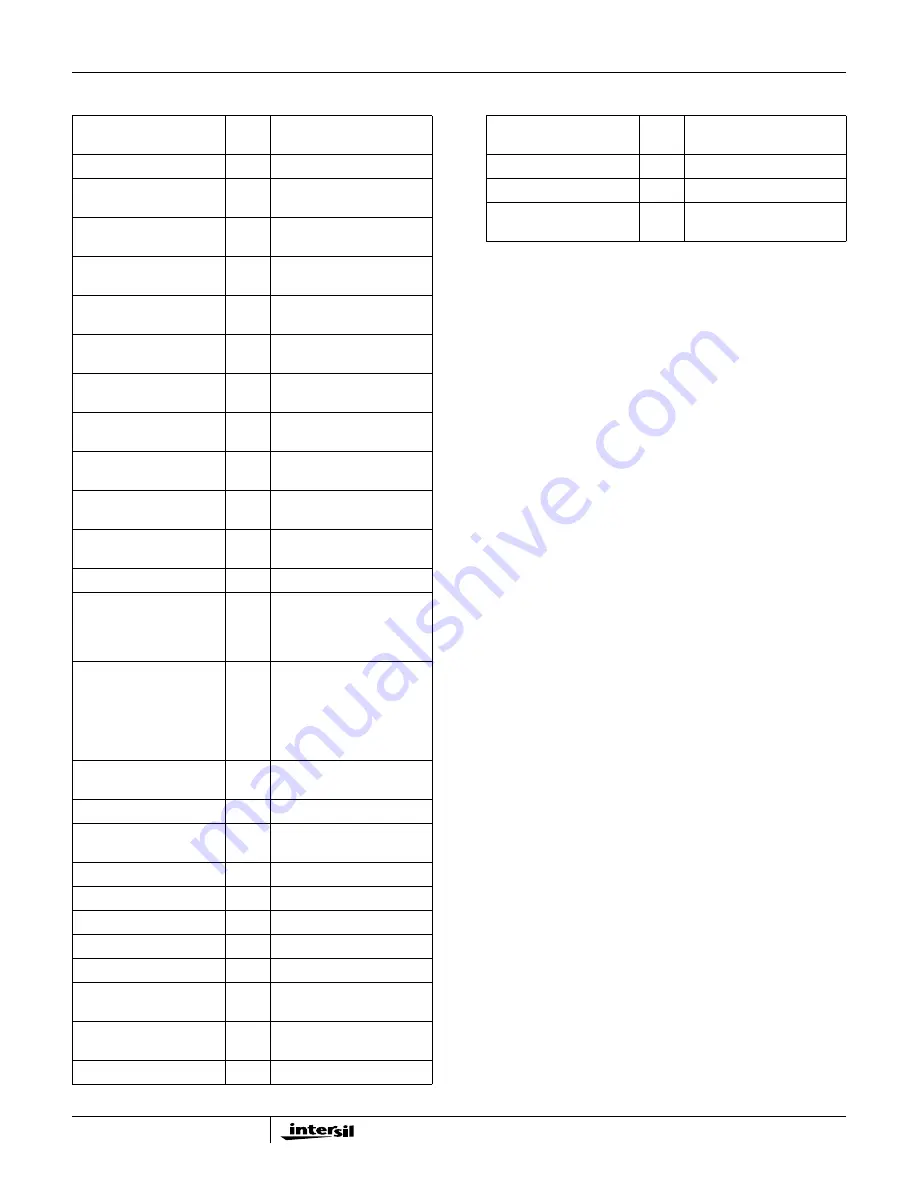

Appendix C Parts List

Appendix D HI5905 Theory of Operation

The HI5905 is a 14-bit fully differential sampling pipelined A/D

converter with digital error correction. Figure 17 depicts the

internal circuit for the converters front-end differential-in-

differential-out sample-and-hold (S/H). The sampling switches

are controlled by internal sampling clock signals which consist

of two phase non-overlapping clock signals,

φ

1 and

φ

2,

derived from the master clock (CLK) driving the converter.

During the sampling phase,

φ

1, the input signal is applied to

the sampling capacitors, C

S

. At the same time the holding

capacitors, C

H

, are discharged to analog ground. At the falling

edge of

φ

1 the input analog signal is sampled on the bottom

plates of the sampling capacitors. In the next clock phase,

φ

2,

the two bottom plates of the sampling capacitors are

connected together and the holding capacitors are switched to

the op amp output nodes. The charge then redistributes

between C

S

and C

H

, completing one sample-and-hold cycle.

The output of the sample-and-hold is a fully-differential,

sampled-data representation of the analog input. The circuit

not only performs the sample-and-hold function, but can also

convert a single-ended input to a fully-differential output for

the converter core. During the sampling phase, the V

IN

pins

see only the on-resistance of the switches and C

S

. The

relatively small values of these components result in a typical

full power input bandwidth of 100MHz for the converter.

As illustrated in the HI5905 Functional Block Diagram and

the timing diagram contained in Figure 18, three identical

pipeline subconverter stages, each containing a four-bit

flash converter, a four-bit digital-to-analog converter and an

amplifier with a voltage gain of 8, follow the S/H circuit with

the fourth stage being only a 4-bit flash converter. Each

converter stage in the pipeline will be sampling in one

phase and amplifying in the other clock phase. Each

individual sub-converter clock signal is offset by 180

degrees from the previous stage clock signal, with the

result that alternate stages in the pipeline will perform the

same operation. The output of each of the three identical

four-bit subconverter stages is a four-bit digital word

containing a supplementary bit to be used by the digital

error correction logic. The output of each subconverter

stage is input to a digital delay line which is controlled by

the internal clock. The function of the digital delay line is to

time align the digital outputs of the three identical four-bit

subconverter stages with the corresponding output of the

fourth stage flash converter before inputting the sixteen bit

result into the digital error correction logic. The digital error

REFERENCE

DESIGNATOR

QTY

DESCRIPTION

-

1

Printed Wiring Board

R16, R19

2

10

Ω

, 1/10W

805 Chip, 1%

R17, R18

2

499

Ω

, 1/10W

805 Chip, 1%

R13

1

56.2

Ω

, 1/10W

805 Chip, 1%

R14

1

A/R

Ω

, 1/10W

805 Chip, 1%

R15

1

22.1

Ω

, 1/10W

805 Chip, 1%

R2, R3

2

100

Ω

, 1/10W

805 Chip, 1%

R4, R12

2

0.0

Ω

, 1/4W

805 Chip, 5%

R5, R6

2

4.99k

Ω

, 1/10W

805 Chip, 1%

R7

1

49.9

Ω

, 1/10W

805 Chip, 1%

R8, R9, R10, R11, R20

5

249

Ω

, 1/10W

805 Chip, 1%

VR1

1

5k

Ω

Trim Pot

C5, C10, C12, C16, C18,

C22, C24, C27, C29, C31,

C33, C35, C39, C41, C42,

C44, C46

17

4.7

µ

F Chip Tant Cap,

10WVDC, 20%, EIA Case A

C1, C2, C4, C6, C7, C8,

C9, C11, C13, C14, C15,

C17, C20, C21, C23, C25,

C26, C28, C30, C32, C34,

C36, C37, C38, C40, C43,

C45, C47

28

0.1

µ

F Cer Cap, 50WVDC,

10%, 805 Case, Y5V

Dielectric

C3

1

A/R pF Cer Cap, 50WVDC,

10%, 805 Case

FB1-7

7

10

µ

H Ferrite Bead

J1, J2

2

SMA Straight Jack PCB

Mount

-

5

Protective Bumper

JP1

1

1x2 Header

JPH1

1

1x2 Header Jumper

P1

1

2x17 Header

TP1, 2, 3, 4

4

Test Point

U1

1

Intersil HI5905IN, 14-Bit 5

MSPS A/D Converter

U4

1

Ultrafast Voltage

Comparator

U2, U3

2

Octal D-type Flip-flop

U5, U6

2

Op-amp

U7

1

Hex Inverter

P2

64-Pin Eurocard RT Angle

Receptacle

REFERENCE

DESIGNATOR

QTY

DESCRIPTION

Application Note 9785