Chapter

3

Operation,

Display

and

Trial

Running

16

cannot be modified. This may be because:

Such a function code is only readable, such as, servo drive model, actually detected

parameter and running record parameter.

Such a function code cannot be modified in the running state and can only be

changed at stop.

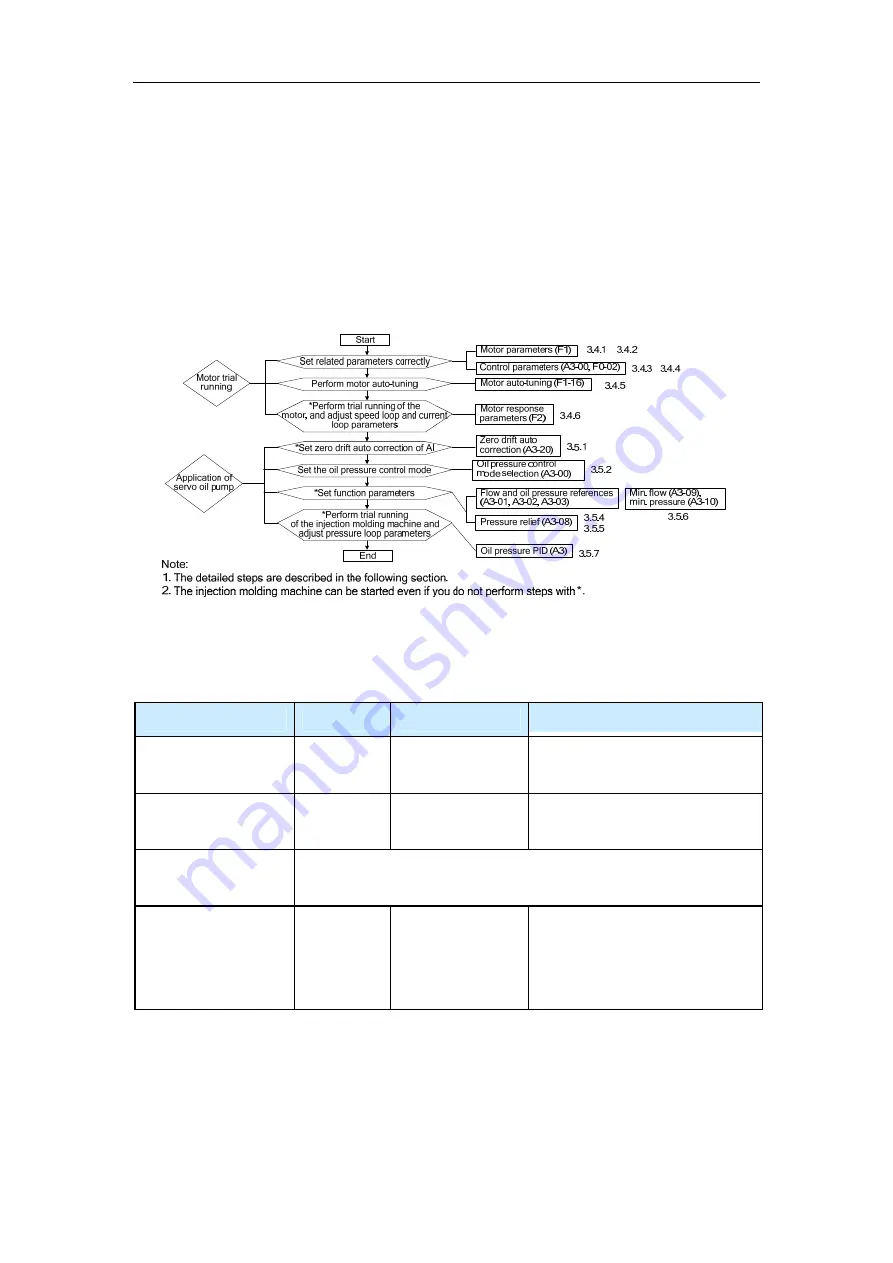

3.3 Flowchart of Commissioning the Servo Hydraulic Pump

Figure 3-4 Flowchart of commissioning the servo hydraulic pump

3.4 Motor Trial Running

3.4.1 Motor Trial Running Procedure

Procedure

Pr. Setting

Value

Description

1. Set the control mode. A3-00 = 0

Non-hydraulic

control mode

The servo drive is set to the

non-hydraulic control mode.

2. Set the command

source.

F0-02 = 0

Operation panel

control

The LOCAL/REMOT indicator on the

operation panel becomes OFF.

3. Perform motor

auto-tuning.

For details, see section 3.4.3 “Setting and Auto-tuning of Motor

Parameters”.

4. Perform motor trial

running

F0-08

Trial running

frequency.

Start trial running in operation panel

control and monitor whether the output

current is normal and whether the

motor runs stably.

3.4.2 Trial Running Check

1) Check whether the running direction of the servo drive is correct. If not, exchange any

two phases of UVW, re-perform motor auto-tuning and then perform motor trial

running.

2) If the motor runs abnormally, check the motor parameters in group F1 and the setting