SAFETY

6

UP6RD–5–175, UP6RM–5–175, UP6RD–5–175

DANGER

Hazard that WILL cause DEATH, SEVERE INJURY or substantial

property damage if ignored. Instructions must be followed precisely to

avoid injury or death.

WARNING

Hazard that CAN cause DEATH, SEVERE INJURY or substantial

property damage if ignored. Instructions which must be followed

precisely to avoid injury or death.

CAUTION

Cautions call attention to instructions which must be followed

precisely to avoid damaging the product, process or its surroundings.

NOTE

Notes are used for supplementary information.

BREATHING AIR PRECAUTION

Ingersoll–Rand air compressors are not designed, intended or

approved for breathing air. Compressed air should not be used for

breathing air applications unless treated in accordance with all

applicable codes and regulations.

General Information

Ensure that the operator reads and understands the decals and

consults the manuals before maintenance or operation.

Ensure that the Operation and Maintenance manual, and the

manual holder, are not removed permanently from the machine.

Ensure that maintenance personnel are adequately trained,

competent and have read the Maintenance Manuals.

Do not point air nozzles or sprayers toward anyone.

Compressed air and electricity can be dangerous. Before

undertaking any work on the compressor, ensure that the electrical

supply has been isolated and the compressor has been relieved of all

pressure.

Wear eye protection when operating or servicing compressor.

All persons positioned near to operating machinery should be

equipped with hearing protection and given instructions on its use in

accordance with workplace safety legislation.

Make sure that all protective covers are in place and that the

canopy/doors are closed during operation.

The specification of this machine is such that the machine is not

suitable for use in flammable gas risk areas.

Installation of this compressor must be in accordance with

recognized electrical codes and any local Health and Safety Codes.

The use of plastic bowls on line filters without metal guards can be

hazardous. Their safety can be affected by either synthetic lubricants,

or the additives used in mineral oils. Metal bowls should be used on a

pressurized system.

Compressed air

Compressed air can be dangerous if incorrectly handled. Before

doing any work on the unit, ensure that all pressure is vented from the

system and that the machine cannot be started accidentally.

Ensure that the machine is operating at the rated pressure and that

the rated pressure is known to all relevant personnel.

All air pressure equipment installed in or connected to the machine

must have safe working pressure ratings of at least the machine rated

pressure.

If more than one compressor is connected to one common

downstream plant, effective isolation valves must be fitted and

controlled by work procedures, so that one machine cannot accidently

be pressurized / over pressurized by another.

Compressed air must not be used for a direct feed to any form of

breathing apparatus or mask.

The discharged air contains a very small percentage of compressor

lubricating oil and care should be taken to ensure that downstream

equipment is compatible.

If the discharged air is to be ultimately released into a confined

space, adequate ventilation must be provided.

When using compressed air always use appropriate personal

protective equipment.

All pressure containing parts, especially flexible hoses and their

couplings, must be regularly inspected, be free from defects and be

replaced according to the Manual instructions.

Compressed air can be dangerous if incorrectly handled. Before

doing any work on the unit, ensure that all pressure is vented from the

system and that the machine cannot be started accidentally.

Avoid bodily contact with compressed air.

All safety valves located in the separator tank must be checked

periodically for correct operation.

Do not over–pressurize the receiver tank or similar vessels beyond

design limits.

Do not use a receiver tank or similar vessels that fail to meet the

design requirements of the compressor. Contact your distributor for

assistance.

Do not drill into, weld or otherwise alter the receiver tank or similar

vessels.

Do not remove, adjust, change, modify or make substitutions for

safety/relief valves, pressure switches or other pressure control

related devices.

Materials

The following substances are used in the manufacture of this

machine and may be hazardous to health if used incorrectly:

.

preservative grease

.

rust preventative

.

compressor coolant

AVOID INGESTION, SKIN CONTACT AND INHALATION OF

FUMES

For further information, consult Material Data Sheet for ALL SEASON

SELECT.

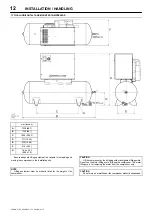

Transport

When loading or transporting machines ensure that the specified

lifting and tie down points are used.

Lifting equipment must be properly rated for the weight of the

compressor.

Do not work on or walk under the compressor while it is suspended.

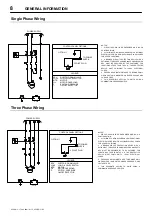

Electrical

Keep all parts of the body and any hand–held tools or other

conductive objects, away from exposed live parts of the compressor

electrical system. Maintain dry footing, stand on insulating surfaces

and do not contact any other portion of the compressor when making

adjustments or repairs to exposed live parts of the compressor

electrical system.

Close and lock all access doors when the compressor is left

unattended.

Do not use extinguishers intended for Class A or Class B fires on

electrical fires. Use only extinguishers suitable for class BC or class

ABC fires.

Attempt repairs only in clean, dry, well lighted and ventilated areas.

Connect the compressor only to electrical systems that are

compatible with its electrical characteristics and that are within its rated

capacity.

Содержание UP6RD-5-175

Страница 2: ......