EN

EN-12

47612267 Rev B

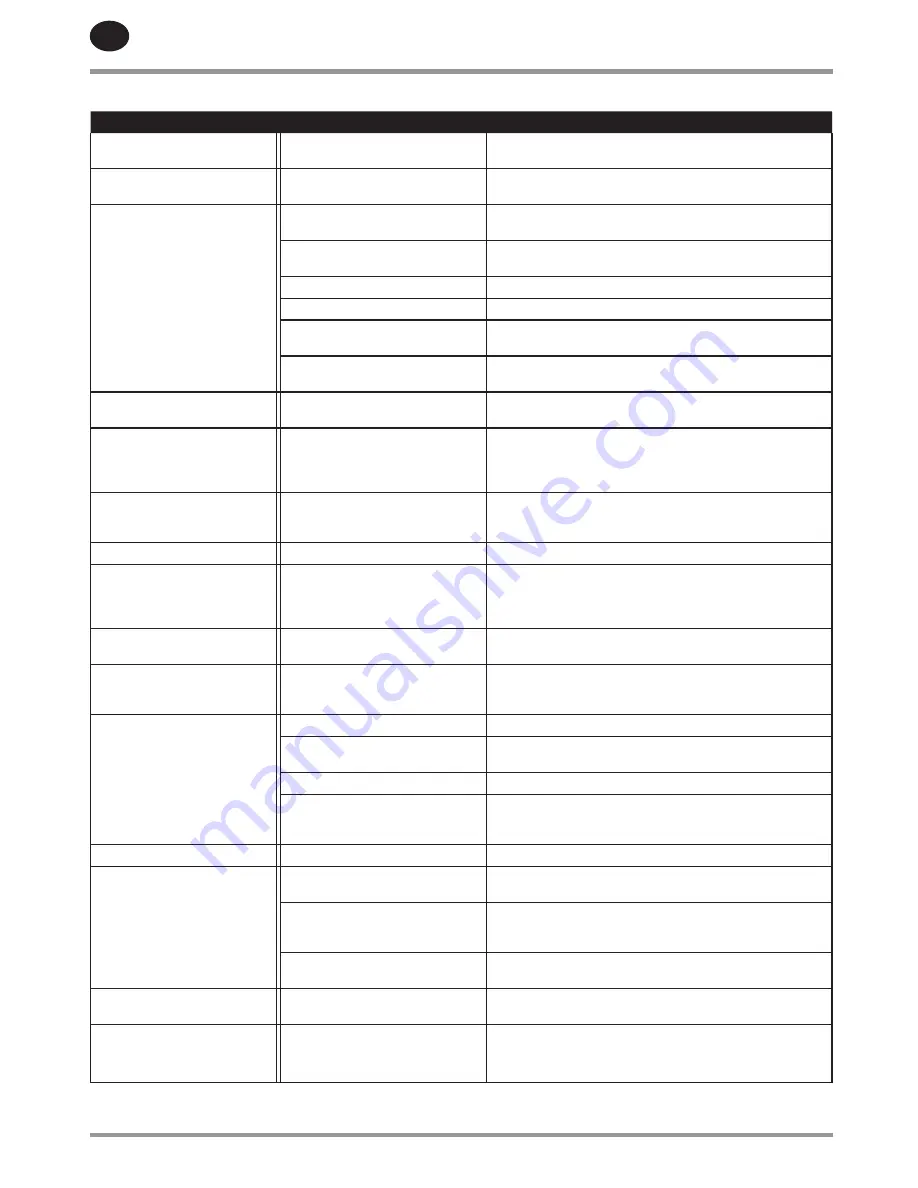

Table 4: Controller Faults (indicated on the controller)

FAULT

CAUSE

REMEDY

Emergency stop.

Emergency stop button has

been pressed.

Identify reason why, repair fault, disengage button and

reset controller.

Blower motor overload.

Blower is blocked, damaged or

blower motor is faulty.

Remove blockage, repair or replace damaged

components.

High airend discharge

temperature.

Compressor operating above

rated pressure.

Check and modify settings. Review system requirements

and contact your local

Ingersoll Rand

representative.

Low coolant level.

Check for leaks. See also ‘discharge air is contaminated

with coolant’. Top up coolant.

High ambient temperature.

Review installation and system parameters.

Insufficient cooling air.

Check ducting and cooling air path.

Dirty, blocked coolant cooler

(cooling air side).

Clean or replace.

Blower motor direction of

rotation incorrect.

Wire correctly.

Check setpoints.

Controller software has been

changed.

Recalibrate all sensors and check setpoints.

Remote start failure.

Remote start button is pressed

after compressor is running or

remote start button remains

closed.

Check operation of buttons or operating procedures.

Remote stop failure.

Remote stop button remains

open and either start button is

pressed.

Check operation of buttons or operating procedures.

Sensor failure.

Sensor is missing or faulty.

Install, repair or replace faulty sensor.

Compressor trips indicating

a high compressor

temperature.

Insufficient cooling taking place.

If compressor is watercooled or sea watercooled, check

that the cooling water is flowing. Check that there is no

air in the water cooling system. Check that the strainer is

not blocked.

Controller has tripped the

compressor.

A fault has occurred.

Repair fault / reset controller.

Invalid calibration.

Calibration done with pressure

in compressor.

Depressurize and re calibrate with pressure pipe to

sensor disconnected. If fault still exists, replace pressure

transducer.

Low sump pressure.

System leak.

Located and repair.

Minimum pressure check valve

faulty.

Repair with service kit.

Blowdown valve faulty.

Repair with service kit.

Loss of control power.

Check 110V circuit breaker.

Check wiring.

Check contactor KM1.

Check motor rotation.

Drive system fault.

Contact your local

Ingersoll Rand

representative.

Change separator element

and/or high sump pressure.

Faulty pressure transducer

measurement.

Calibrate and validate the wet sump and package

discharge transducers.

Moisture separator condensate

drain trap faulty.

Ensure condensate drain system is functioning

properly, and condensate is being drained. See Table 4:

Troubleshooting Chart.

Separator element dirty or

blocked.

Change separator element.

Machine stops but no alarm

message

Loss of outputs of control power.

Check controller outputs (110V AC) power supply (fuses/

mini circuit breaker).

Motor current fault

Loss of control power.

Sump pressure too high.

Faulty motor or Airend.

Check control power circuit and breaker.

Check separator element pressure drop.

Contact your local Ingersoll Rand representative.

RELEASED 11/Feb/2019 01:43:20 GMT