Use a premium anti-wear (AW) hydraulic fluid in the hydraulic system. The following

specifications are intended to serve as a general guide in selecting suitable oils.

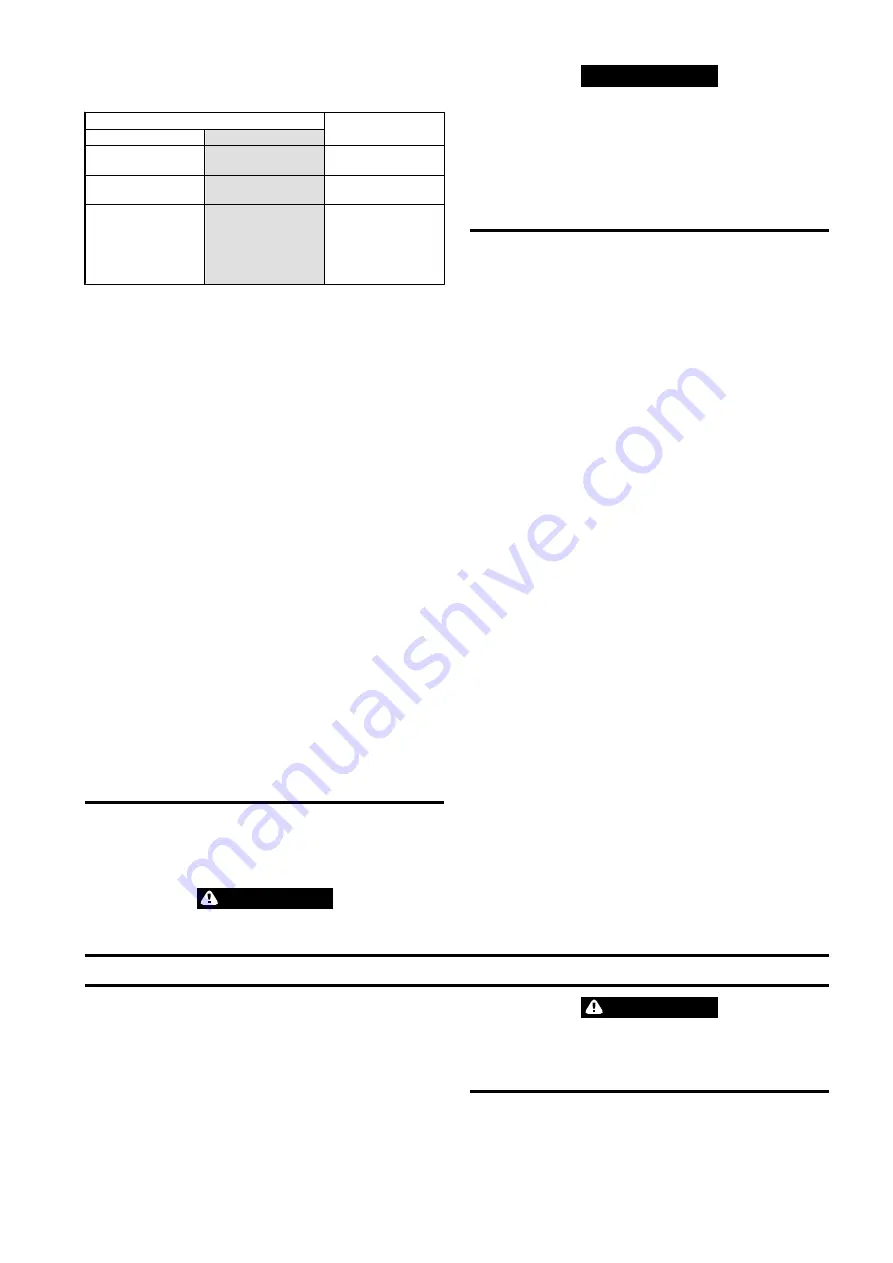

Table 5: Recommended Hydraulic Oil

Temperature

Recommended Hydraulic

Oil

Fahrenheit

Celsius

above 32° F

0° C

ISO VG 46

(SSU 230-240 @ 100° F)

0° to 32° F

-17.7° to 0° C

ISO VG 32

(SSU 60-165 @ 100° F)

below 0° F

below -17.7° C

Consult local oil company

representative for oil

having a maximum

viscosity of 7,400 SSU’s at

the minimum temperature

encountered.

n

Filters

Filters should be equipped with dirty filter indicators, which should be checked daily.

Replace filters if indicators show filter is dirty. It is also recommended that filters be

changed if hydraulic oil is changed or a major component (pump, valve, motor, etc.)

is repaired or replaced.

When product is installed with its own hydraulic system or when there is no filter in

existing circuit, a partial flow microfilter should be installed between control valve

and reservoir. This filter should be rated at Beta 200=6μm. Filters must include an

integral 345 kPa/3.45 bar (50 psi) bypass check valve which will open when filter

element is filled to 80% capacity.

Refer to ‘Filter Maintenance’ in “MAINTENANCE” section for servicing information.

n

Connections

When repairing or servicing any hydraulic lines or fittings in the system, always flush

each line and connection of all foreign contaminants before making the final

connection. Always cap or plug open connections or lines. Verify port connections

match motor and installation information provided.

n

Pump

Ensure pump used with motor is capable of producing pressure and volume as specified

for the product.

n

Controls

Ensure control valve moves smoothly in both directions before operating product with

full load.

n

Motor

For optimum performance and maximum durability of parts, ensure hydraulic supply

does not exceed recommended pressures and flows. When feasible motor should be

installed as near as possible to the pump. Refer to Table 2 ‘Specifications’

on page 4. Motor case drain lines must be ported to reservoir and must not exceed

207 kPa/2 bar (30 psi).

n

Reduction Gear

Product is shipped with petroleum based cooling oil. Prior to operation, check oil

level. Refer to “LUBRICATION” section on page 7.

n

Chain Container

Refer to Dwg. MHP2658 and MHP3059 in Product Parts Information Manual.

Check the chain container size to make sure the length of the load chain is within

the capacity of the chain container. Replace with a larger chain container if required.

WARNING

• Allow chain to pile naturally in the chain container. Load chain that does not

pile naturally can chafe excessively, leading to sparks.

NOTICE

• Make certain to adjust the balance chain so that the chain container does not

contact the load chain.

n

Attaching Limit Stop

Refer to “MAINTENANCE” section in Product Maintenance Information Manual.

1. On hoists without a chain bucket, slide buffer and limit stop washer onto chain.

2. Install limit stop as described under “Load Chain Replacement”.

3. Run hoist slowly in the both directions to verify limit stops activate and hoist

ceases to operate.

n

Trolley Rack Drive (optional)

Install the trolley rack drive onto the support beam. Installation should only be done

by authorized service personnel.

n

Pre-Installation Checks

Refer to Dwg. MHP2990 on page 10,

A

. Rack;

B

. Pinion;

C

. Maintain clearance

between rack and pinion teeth of 0.16 inch (minimum) to 0.20 inch (maximum) [4

to 5 mm] to prevent pinion binding during operation. Measure gap between the

outside diameter of drive pinion and root of rack segment.

Before welding the rack segments onto the trolley beam, install the rack segments

on the bottom of the beam lower flange and clamp in place. Mount the trolley on the

lower beam flange. Measure the gap between the outside diameter of the drive pinion

and root of rack segment teeth. As shown in Dwg. MHP2990, the trolley drive pinion

and rack teeth must have a 0.16 to 0.20 inch (4 to 5 mm) clearance.

n

To Adjust Clearance

Refer to Dwg. MHP2991on page 10,

A

. Mounting Capscrew;

B

. Jam Nut;

C

.

Adjustment Screw.

There is an adjustment screw located below the reducer adapter.

1. Loosen capscrews attaching trolley drive to sideplate.

2. Loosen jam nut and rotate adjustment screw to achieve clearance as shown inDwg.

3. Tighten jam nut and mounting screws.

If a larger adjustment is required:

1. Add shims between the rack segment and beam to decrease distance.

2. Remove material from rack segment to increase distance.

n

Installing Rack Segments Onto Beam

Refer to Dwg. MHP1178 on page 10,

A

. Hoist Trolley Drive Assembly mounted this

side;

B

. Lower Beam Flange;

C

. Rack Segment;

D

. Fillet Weld: Allow 1/4 inch (6.5 mm)

clearance between edge of lower flange and rack segment. Apply weld to both sides

of rack segment. Refer to Dwg. MHP3016 on page 10,

A

. Stagger welds along rack;

B

. (Not to scale);

C

. Check clearance between racks;

D

. Use the rack guide for correct

track positioning.

Rack segments should be installed on the outside edge of the lower flange of the

trolley beam. Allow 1/4 inch (6.5 mm) clearance between the edge of the lower flange

and rack segment for fillet weld. The rack segments should be clamped tight against

the lower flange so that there is no sagging. Sagging of the rack could cause the drive

pinion to bind as it traverses along the runway beam.

Racks are provided in segments. These segments should be tack welded (refer to

Dwg. MHP3016 on page 10) in place and the trolley traversed the entire length.

During this movement observe for any high or low spots and correct. Also check each

segment connection for drive tooth contact and correct as necessary. When all

clearances are achieved, weld both sides of the rack to the beam flange to prevent

corrosion between the rack segment and beam.

OPERATION

It is recommended that the user and owner check all appropriate and applicable

regulations before placing this product into use. Refer to Product Safety Information

Manual.

The product operator must be carefully instructed in his or her duties and must

understand the operation of the product, including a study of the manufacturer’s

literature. The operator must thoroughly understand proper methods of hitching loads

and should have a good attitude regarding safety. It is the operator’s responsibility

to refuse to operate the product under unsafe conditions.

WARNING

• The product is not designed or suitable for lifting, lowering or moving people.

• Never lift loads over people.

• The hook latch is intended to retain loose slings or devices under slack

conditions. Use caution to prevent the latch from supporting any of the load.

• Refer to Product Safety Information Manual before operating any product.

n

Hydraulic System

Efficient operation of the product requires attention to hydraulic oil system. The most

important elements to ensure proper operation of the hydraulic system are:

Form MHD56465 Edition 3

5

Содержание Liftchain LC2H060S

Страница 11: ...SERVICE NOTES Form MHD56465 Edition 3 11...

Страница 12: ...www ingersollrandproducts com...