4

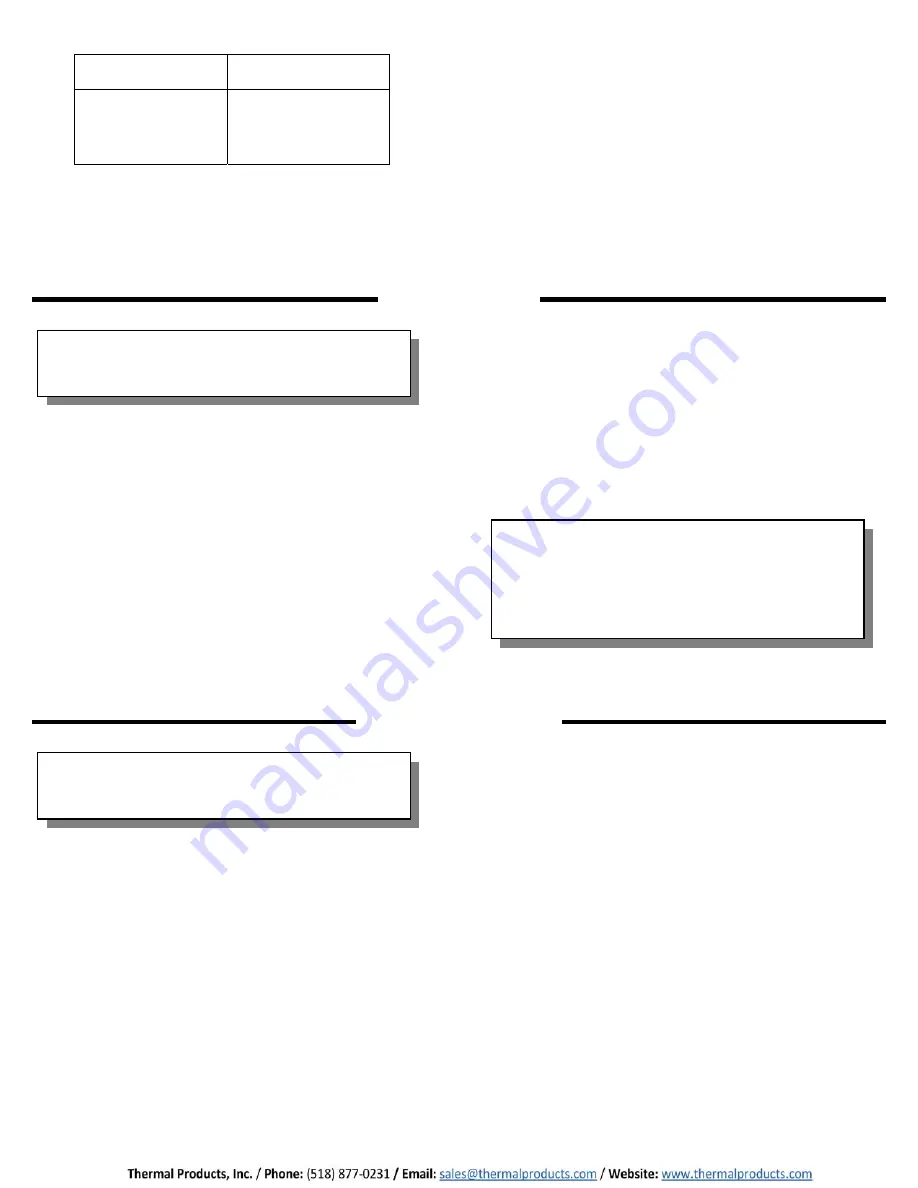

Sheath

Material

Maximum

Sheath Temperature

Copper

350

q

F

Steel

750

q

F

Stainless Steel 304

1400

q

F

Incoloy 800

1600

q

F

DO NOT

operate heaters at flow rates below the design

flow range. Reduced flow can shorten heater life, cause

nuisance tripping of thermal safeties, or potentially exceed

vessel shell design temperatures. Note that heaters with

SCR control can typically operate at reduced flows down to

1/10

th

of the design flow if the controller is properly tuned,

and over-temperature safety devices are set at an

appropriate point to protect the heater and fluid.

INDEECO recommends that all safety interlocks are tested

during initial startup to ensure they properly disable the

heater. After 10 days of operation, retighten all electrical

connections.

On Flanged Immersion heaters, re-tighten heater flange

bolts after the heater has completed one or two heating

cycles.

MAINTENANCE

Periodically check all electrical connections, including field

and factory-made connections for tightness, and all wiring

for deterioration at least once a year.

Periodically inspect for leakage and retighten Immersion

Heater flange bolts when required.

Inspect the terminal enclosure and conduit connections for

evidence of water leaks or moisture collection. Tighten

connections as required. Clean up any corrosion. Do not

continue using a heater with signs of damage.

Where the heater is installed in cold climates, consider

safety precautions to prevent damage due to freezing fluid

when the heater is not in service.

Where buildup of solids on the heating elements or

significant corrosion is expected, periodically remove the

Immersion Heater to inspect the vessel and heating

elements. Do not continue using a heater with signs of

damage. Before removing, note the orientation of the

flange or pipe plug relative to the vessel. Place a reference

mark on the vessel and Immersion Heater or use other

methods, such as drawing a sketch showing the conduit

hub orientation, to ensure proper orientation when re-

installing.

TROUBLESHOOTING

The nature of the magnesium oxide used to electrically

isolate the nickel chromium resistance wire in the heating

elements is such that over a long period of storage, they will

absorb considerable moisture from the atmosphere unless

hermetically sealed. It is recommended to perform an

insulation resistance test prior to energizing the equipment.

If the value is less than 1 Meg Ohm using a 500Vdc or

similar tester, care must be taken to dry out the heater to

prevent failure. It is recommended that the elements be

turned on at a reduced voltage at first to boil off the

moisture. Meg Ohm readings may drop initially after a few

minutes of operation, indicating moisture being forced out of

the elements. The terminal enclosure lid should be left

open during this period to allow the moisture to escape.

If the heater has a manual-reset high limit thermostat, be

sure that the reset button is pressed in.

The heating elements are not field-repairable. The only

recommended field repairs are to remove and replace the

faulty Immersion Heater, or to return the heater to the

factory for repair. Refer to instruction manual 72-2010-83 or

70-2010-83 for details on the Immersion Heater.

If reduced heat output is suspected, verify the condition of

the heating elements by using an ammeter to check the

current draw of each input line. All input lines should draw

approximately equal current, which should agree with

nameplate rating. If they do not, one or more of the heating

elements could be damaged.

CAUTION

Troubleshooting and repair should only be

attempted by qualified maintenance personnel.

CAUTION

Troubleshooting and repairs should only be

attempted by qualified maintenance personnel.

CAUTION

Immersion Heaters with cross-baffles or over-

temperature thermocouples are specifically oriented

to match the vessel. Do not rotate the Immersion

Heater without consulting with the factory.