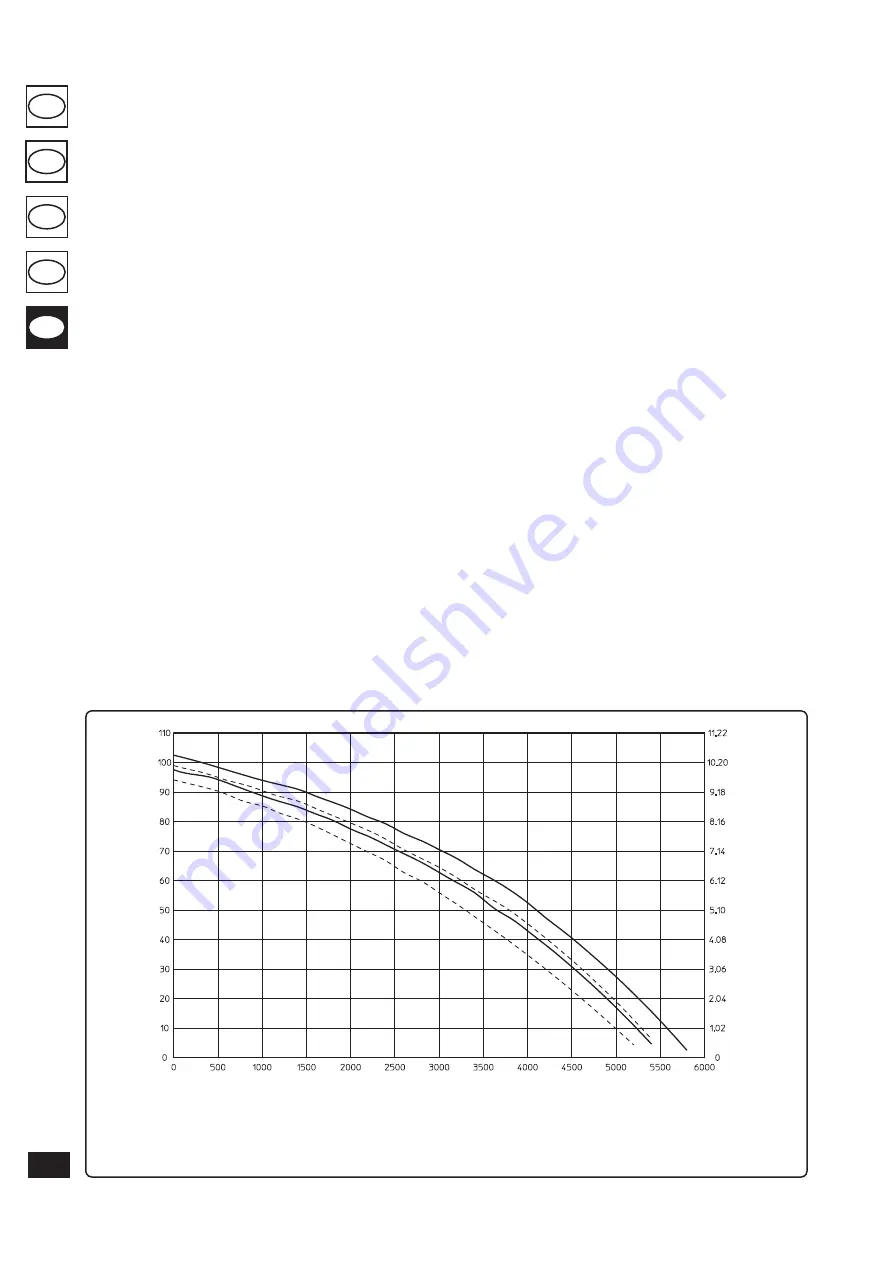

Total head available to the system.

Fig. 1-24

1.16 GAS SYSTEM START-UP.

To start up the system proceed as follows:

- open windows and doors;

- avoid presence of sparks or naked flames;

- bleed all air from pipelines;

- check that the internal system is properly sealed

according to specifications.

1.17 BOILER START-UP (IGNITION).

For issue of the Declaration of Conformity pro-

vided for by Italian Law, the following must be

performed for boiler start-up:

- check that the internal system is properly sealed

according to specifications;

- make sure that the type of gas used corresponds

to boiler settings;

- switch the boiler on and check correct igni-

tion;

- check that the n° of fans revs is that indicated

in the book (Par. 3-21);

- ensure that the safety device is engaged in the

event of gas supply failure and check activation

time;

- check activation of the main switch located

upstream from the boiler and in the boiler;

- check that the intake/exhaust concentric ter-

minal (if fitted) is not blocked.

The boiler must not be started up even if only

one of the checks should be negative.

N.B.:

the boiler preliminary check must be carried

out by a qualified technician. The boiler warranty

is valid as of the date of testing.

The test certificate and warranty is issued to the

user.

1.18 CIRCULATION PUMP.

The “Victrix 115 1 I” series boilers are supplied

with a built-in circulation pump with 3-posi-

tion electric speed control. The boiler does not

operate correctly with the circulation pump on

first speed. To ensure optimal boiler operation,

in the case of new systems (single pipe and

module) it is recommended to use the pump

at maximum speed. The pump is already fitted

with a condenser.

Pump release.

If, after a prolonged period of

inactivity, the circulation pump is blocked,

unscrew the front cap and turn the motor shaft

using a screwdriver. Take great care during this

operation to avoid damage to the motor.

1.19 KITS AVAILABLE ON REQUEST.

• Cascade and zones heat adjuster kit.

• Support kit for fixing the heat adjuster to the

wall.

• Zone manager kit.

• Modulating room thermostat kit.

• External probe kit.

• System flow probe kit.

• DHW probe kit for external storage tank.

• Anti-freeze with -15 °C resistance kit.

• Individual boiler safety devices stub pipes kit.

• Boilers in cascade safety devices stub pipes

kit.

• Three-way valve kit for coupling external sto-

rage tank unit.

• Individual boiler hydraulic manifold kit.

• Hydraulic connection manifolds kit with two

boilers in cascade.

• Additional boiler in cascade hydraulic manifold

kit.

• Flue exhaust manifold kit with flue adjusting

devices with two boilers in cascade.

• Flue exhaust manifold kit with flue adjusting

device with additional boiler in cascade.

• Ø80/125 horizontal concentric kit.

• Ø80/125 vertical concentric kit.

• Ø 80 horizontal kit with flue exhaust.

• Ø 80 horizontal terminal kit with wall flue

exhaust.

• Ø80 vertical terminal kit.

The above-mentioned kits are supplied complete

with instructions for assembly and use.

A = Head available to the system on the individual boiler maximum speed.

B = Head available to the system on the individual boiler second speed.

C = Head available to the system on maximum speed with the non-return valve for boilers in cascade (battery)

D = Head available to the system on second speed with the non-return valve for boilers in cascade (battery)

H

ea

d (m H

2

O)

Flow rate (l/h)

H

ea

d (kP

a)

A

B

C

D

124

TR

SI

RU

IE

CZ

Содержание VICTRIX 115 1 I

Страница 2: ......

Страница 145: ......

Страница 146: ...www immergas com This instruction booklet is made of ecological paper Cod 1 029592 Rev 15 031093 001 01 10 ...