Fuel gas quality.

The appliance has been designed

to operate with gas free of impurities; otherwise it

is advisable to fit special filters upstream from the

appliance to restore the purity of the gas.

Storage tanks (in case of supply from LPG

depot).

- New LPG storage tanks may contain residual

inert gases (nitrogen) that degrade the mixture

delivered to the appliance casing functioning

anomalies.

- Due to the composition of the LPG mixture,

layering of the mixture components may occur

during the period of storage in the tanks. This

can cause a variation in the heating power of

the mixture delivered to the appliance, with

subsequent change in its performance.

Hydraulic connection.

Important:

In order not to void the warranty

before making the boiler connections, carefully

clean the heating system (pipes, radiators, etc.)

with special pickling or de-scaling products to

remove any deposits that could compromise

correct boiler operation.

It is recommended to prepare a filter in the

system to collect and separate any impurities

present in the system (slurry remover filter).

In order to avoid scaling in the central heating

system, the provisions given in the regulations on

water treatment in heating systems for civil use

must be respected. Water connections must be

made in a rational way using the couplings on the

boiler template. The discharge of the boiler safety

valve must be connected to a discharge funnel

that is present in the boiler but not installed

and then connected to a sewer. Otherwise, the

manufacturer declines any responsibility in case

of flooding if the drain valve cuts in.

Condensate drain.

To drain the condensate pro-

duced by the appliance, it is necessary to connect

to the drainage system by means of acid conden-

sate resistant pipes having an internal diameter

of at least 13 mm. The system connecting the

appliance to the drainage system must be carried

out in such a way as to prevent freezing of the

liquid contained in it. Before appliance start-

up, ensure that the condensate can be correctly

removed. Also, comply with national and local

regulations on discharging waste waters.

Electrical connection:

The electric plant must be

realised in compliance with the law. The “Victrix

115 1 I” boiler has an IPX5D protection rating for

the entire appliance. Electrical safety of the unit

is reached when it is correctly connected to an

efficient earthing system as specified by current

safety standards.

Important:

Immergas S.p.a. declines any respon-

sibility for damage or physical injury caused by

failure to connect the boiler to an efficient earth

system or failure to comply with the reference

standards.

Also ensure that the electrical installation cor-

responds to maximum absorbed power speci-

fications as shown on the boiler data-plate. The

boilers are supplied complete with an “X” type

power cable without plug. The power supply cable

must be connected to a 230V ±10% / 50Hz net-

work respecting the L-N polarity and the earth

connection

, An omnipolar disconnection

must be envisioned on this network with a class

III overvoltage category. The main switch must

be installed outside the rooms in a position that

is indicated and accessible. When replacing the

power supply cable, contact a qualified techni-

cian (e.g. the Immergas After-Sales Technical

Assistance Service). The power cable must be

laid as shown.

In the event of mains fuse replacement on the

connection terminal board, use a 2A quick-

blow fuse. For the main power supply to the

appliance, never use adapters, multiple sockets

or extension leads.

If during connection the L-N polarities are not

respected, the boiler does not detect flame pre-

sence and goes into ignition block.

Important:

also in the case in which the L-N

polarity is not respected, if there is temporary

residual voltage exceeding 30V on the neutral,

the boiler could function all the same (but only

temporarily). Measure the voltage using appro-

priate instruments, without trusting the voltage

tester screwdriver.

1.8 COMMANDS FOR HEAT

ADJUSTMENT (OPTIONAL).

The boiler is prepared for the application of a

cascade and zone regulator, zone manager and

external probe.

These components are available as separate kits

to the boiler and are supplied on request.

Carefully read the user and assembly instructions

contained in the accessory kit.

• The cascade and zone regulator (Fig. 1-6) is

connected to the boiler using only two wires,

powered at 230 V and allows to:

- manage a hydraulic circuit with 2 mixed

zones (mixing valve); 1 direct zone; 1 Storage

tank unit and relative pumps;

- self-diagnosis system to display any boiler

functioning anomalies;

- to set two room temperature values: one for

day (comfort temperature) and one for night

(lower temperature);

- to manage the temperature of the DHW (with

a storage tank unit);

- to manage the boiler flow temperature de-

pending on the external temperature;

- to select the desired operating mode from

the various possible alternatives for each

individual hydraulic circuit:

- permanent operation in comfort temp;

- permanent operation in lower temp;

- permanent operation in adjustable anti-freeze

temp.

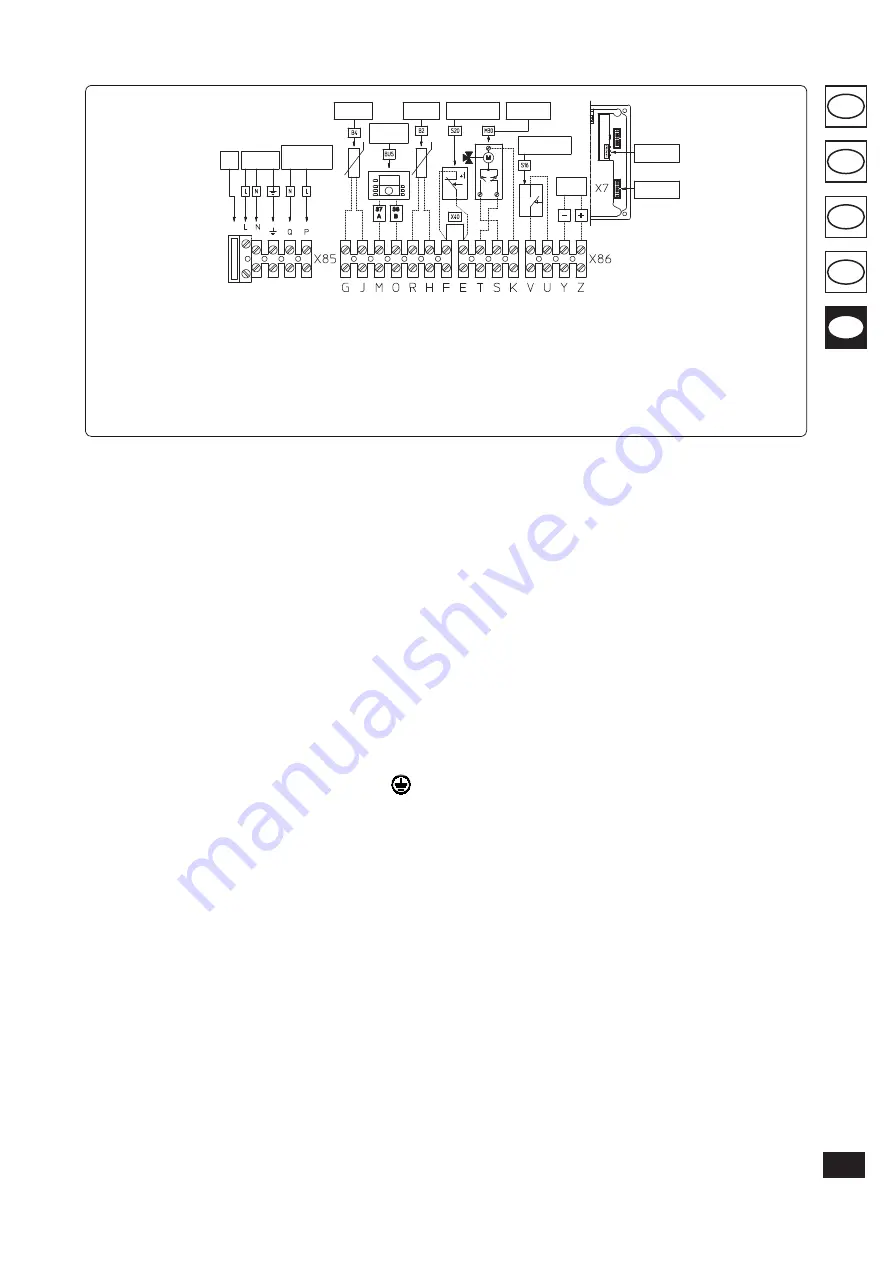

Fig. 1-4

Key:

1 - Fuse 2AF

2 - 230 Vac - 50 Hz

3 - External pump (optional) Max.

1A

4 - External probe (Optional)

5 - Heat adjuster (Optional)

6 - Boiler probe (Optional)

7 - Room Thermostat (Optional)

8 - 3-way valve (Optional)

9 - Summer Switch (Optional)

10 - Analogue input

11 - Clip in for cascade addresses

management

12 - Data download serial interface

117

TR

SI

RU

IE

CZ

Содержание VICTRIX 115 1 I

Страница 2: ......

Страница 145: ......

Страница 146: ...www immergas com This instruction booklet is made of ecological paper Cod 1 029592 Rev 15 031093 001 01 10 ...