ES

CZ

HU

SL

HR

102

IE

PL

IE

ES

103

CZ

HU

SL

HR

PL

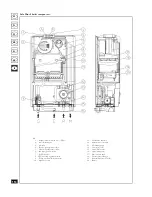

Gas connection (Appliance category II

2H3+

).

Our boilers are built to operate on methane gas (G20) and

LPG. Feed piping must be the same as or larg er than the

3/4"G boiler fi tting. Before making the gas connection,

carefully clean inside all the fuel feed system piping in order

to remove any residuals that could impair good boiler ope-

ration. Also make sure the gas corresponds to boiler speci-

fi cations (see boiler dataplate). If diff erent, the boiler must

be con vert ed for operation with the other type of gas (see

unit conversion in case of gas change). It is also im por tant to

check the dynamic pressure of the gas supply (natural gas or

LPG) to be used for feeding the boiler which must conform,

as insuffi cient pressures can reduce generator power, causing

the user in con ven ienc es.

Ensure that the gas cock connection is carried out correctly,

following the assembly sequence shown in the fi gure. e

gas supply pipe must be suitably dimensioned according to

current standards in order to guarantee correct gas delivery to

the boiler even in conditions of maximum gen er a tor output

and to guarantee the unit’s performance (technical data). e

coupling system must conform to standards.

Gas quality.

e unit is designed to operate with fuel gas free

of impurities; otherwise, suitable fi lters should be installed

ahead of the unit in order to re store fuel purity.

Storage tanks (in case of feed from LPG tank).

- New LPG storage tanks can contain residuals of inert gases

(nitrogen) which weaken the mixture delivered to the unit,

causing anomalous op er a tion.

- Due to the composition of the LPG mixture, lay er ing of

the mixture’s components can occur during the period of

storage in the tanks. is can cause a change in the heating

power of the mixture de liv ered to the unit, with subsequent

variation in its performance.

Water connection.

Before making the connections, all sy-

stem piping must be carefully cleaned to re move any residuals

that could impair boiler effi cien cy. In order to prevent scaling

in the heating system, the provisions contained in standard,

con cern ing the treatment of water in heating systems for

civil use, must be complied with. Water connections must be

made in a rational way, using the connections on the boiler

template. e boiler safety valve outlet must be connected to

a discharge funnel. Otherwise, the manufacturer declines any

responsibility in case of fl ooding if the drain valve cuts in.

Electrical Connection

. e Eolo Mini S boiler is de signed

with IPX4D protection rating. Electrical safe ty of the unit is

guaranteed when correctly connected to an effi cient earthing

system as specifi ed by cur rent safety standards.

Caution

: Immergas S.p.A. declines all liability for damage

or physical injury caused by failure to con nect the boiler to

an effi cient earthing system or fail ure to observe reference

standards.

Also ensure that the electrical installation cor re sponds to

maximum absorbed power specifi cations as shown on the

boiler dataplate.

Boilers are supplied complete with an “X” type pow er ca-

ble without plug. e power plug must be con nect ed to a

230V-50Hz mains with the correct pole sequence L-N and

the earth connection; the mains must also be equipped with

a multi-pole cir cuit break er with a contact opening gap of

at least 3 mm.

In the event of power cable replacement, contact for example

an Authorised Immergas Service Centre for as sist ance.

e power cable must be laid.

In the event of mains fuse replacement on the con trol card,

use a 2A quick blow fuse. For the main pow er supply to the

appliance, never use adapters, multiple sockets or extension

leads.

N.W.

: when connecting the appliance, if the correct L-N

polarity is not observed the boiler does not de tect the fl ame

and inhibits start-up. Also in the same case, if the neutral

is powered with residual voltage over 30V, the boiler will

probably operate, but only temporarily. Measure the voltage

readings with suit a ble tools; avoid the use of mains tester

screw driv er. If the power supply is phase-phase type at 230V,

to guarantee safe con di tions equivalent to existing con di tions

when the boil er is powered with a Phase-Neu tral mains, an

adaptor kit must be fi tted on the boiler for Phase-Phase

mains, available on request. Con tact an Authorised Immergas

Service Centre for in stal la tion of the kit.

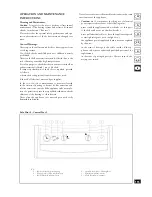

Room thermostat electrical connection On/Off .

Eolo

Mini S boilers are designed for use with an room thermo-

stat or chronothermostat On/Off . and clock programmer.

If you have only one of these devices, connect to ter mi nals

6 and 9 and remove jumper P1. Whereas if you have both,

connect (TA) on terminals 8 and 9, and (CP) on terminals

6 and 7, after removing P1.

Caution:

Boiler pipelines must never be used to earth the

electrical or telephone lines. Ensure elimination of this risk

before making the boiler electrical con nec tions.

Installing air intake and fl ue exhaust ter mi nals.

Immergas supplies various solutions separately from the

boiler for the installation of air intake and fl ue extraction,

fundamental for boiler operation.

N.W.: e boiler must be installed exclusively with an

original Immergas air intake and fl ue ex trac tion system

as specifi ed by standards. is system is identifi able by

a special iden ti fi ca tion mark bearing the note: “not for

con dens ing boilers”.

e fl ue ducts have not to be near or in contact with infl am-

mable materials, and they have not to pass through buildings

and walls made of infl ammable materials.

Key:

1 - Gas valve

2 - Flat seal

3 - Gas cock

4 - Gas pipe