-4-

www.igmtools.com

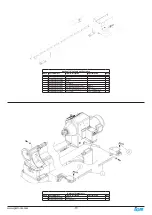

Tail stock viewed from the front

Pic. 7

Tool rest

The tool rest can be moved to any position on

the lathe bed and locked to suit the job at hand.

The tool rest has a tall profile to allow the bowl

turner to turn steep angles. The leading edge

is made from 6 mm hardened steel.

Tool rest assembled to the bed

Pic. 8

Tool rest

Pic. 9

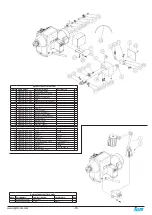

Electrical system

220V: The electrical control system (VFD) is

housed at the back of the head stock, The VFD

converts single phase 220v to three phase.

There is a speed readout at the front of the

lathe with controls to fine adjust the rpm of

the spindle. A power cord with 220V plug is

provided.

Tail stock travel

114 mm

Tail stock removal Self-ejecting

Tail stock taper

MT 2

Faceplate

76 mm

Bed material

Steel

Weight (net/ship)

242 kg / 255 kg

3.3 Noise emissions

Equivalent A-weighted Sound pressure level

according to EN ISO 3746: 75.66 dB(A).

Uncertainty, K in decibels: 4.0 dB (A) according

to EN ISO 4871 The figure quoted is emission

levels and are not necessarily safe working

levels. Whilst there is a correlation between the

emission and exposure levels, this cannot be

used reliably to determine whether or not further

precautions are required. Factors that influence

the actual level of exposure of the workforce

include characteristics of the work room, the

other sources of noise, etc. i.e. the number of

machines and other adjacent processes. Also

the permissible exposure level can vary from

country to country, This information, however,

will enable the user of the machine to make a

better evaluation of the hazard and risk.

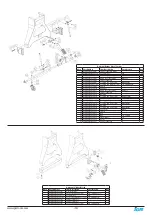

Pic. 13

4. General safety

“WARNING“: For Your Own Safety Read

Instruction Manual before Operating Lathe

4.1

Safety Rules

(a) Wear eye protection.

(b) Do not wear gloves, a necktie, or loose

clothing.

(c) Tighten all locks before operating.

(d) Rotate work piece by hand before applying

power.

(e) Rough out work piece before installing on

faceplate.

(f) Do not mount split work piece or one

containing a knot.

(g) Use lowest speed when starting new work

piece.

• Keep guards in place and in working order.

• Remove adjusting keys and wrenches. Form

habit of checking to see that keys and adjusting

wrenches are removed from tool before turning

it on.

• Keep work area clean. Cluttered areas and

benches invite accidents.

• Don‘t use in a dangerous environment. Don‘t

use power tools in damp or wet locations, or

expose them to rain. Keep work area well

lighted.

VFD with cover open

Pic. 10

Power cord

Pic. 11

Tool storage

A tool storage bracket which can be mounted

on either leg.

Tool storage bracket

Pic. 12

3.2 Technical data

Motor

Induction,1725RPM, 3 HP 220V

Voltage

220V, 60 Hz, 1 Ph.

3 phase output

Recommended breaker size

16 A, tripping

characteristic C (16/1/C).

Swing over bed

609 mm

Swing over banjo

501 mm

Outboard swing max.

965 mm

Distance between centres

914 mm

Floor to spindle centre

1130 mm

Floor to bed height

826 mm

Dim. W x D x H

1524 x 660 x 1327 mm

Tool rest

305 mm

Speed range high:

135 – 3500 rpm

Speed range low:

50 – 1300 rpm

VFD

DeltaS1 variable frequency drive

Spindle

1.25” x 8 tpi right hand thread

Spindle taper

MT 2

Spindle lock

Spring loaded

Spindle indexing

14 / 36 / 48 with lock

Head stock and tail stock bore 9,5 mm

Содержание LAGUNA 2436

Страница 2: ...2 www igmtools com...

Страница 12: ...12 www igmtools com Electrical drawing Wiring diagram for control panel on headstock...

Страница 13: ...13 www igmtools com Exploded view drawings and parts list Wiring diagram for remote control...

Страница 14: ...14 www igmtools com...

Страница 20: ...20 www igmtools com...

Страница 21: ...21 www igmtools com...