32

4

Help

This section gives a number of suggestions allowing problems that may arise when using your printer to be pinpointed. If you do not manage to solve your

problem, this section also explains how to contact IDville technical support.

4-1 Warnings and Diagnosis

Although the ID Maker printer was designed to work independently, keeping user involvement to a minimum, it may nonetheless prove useful to gain some

familiarity with the main warnings.

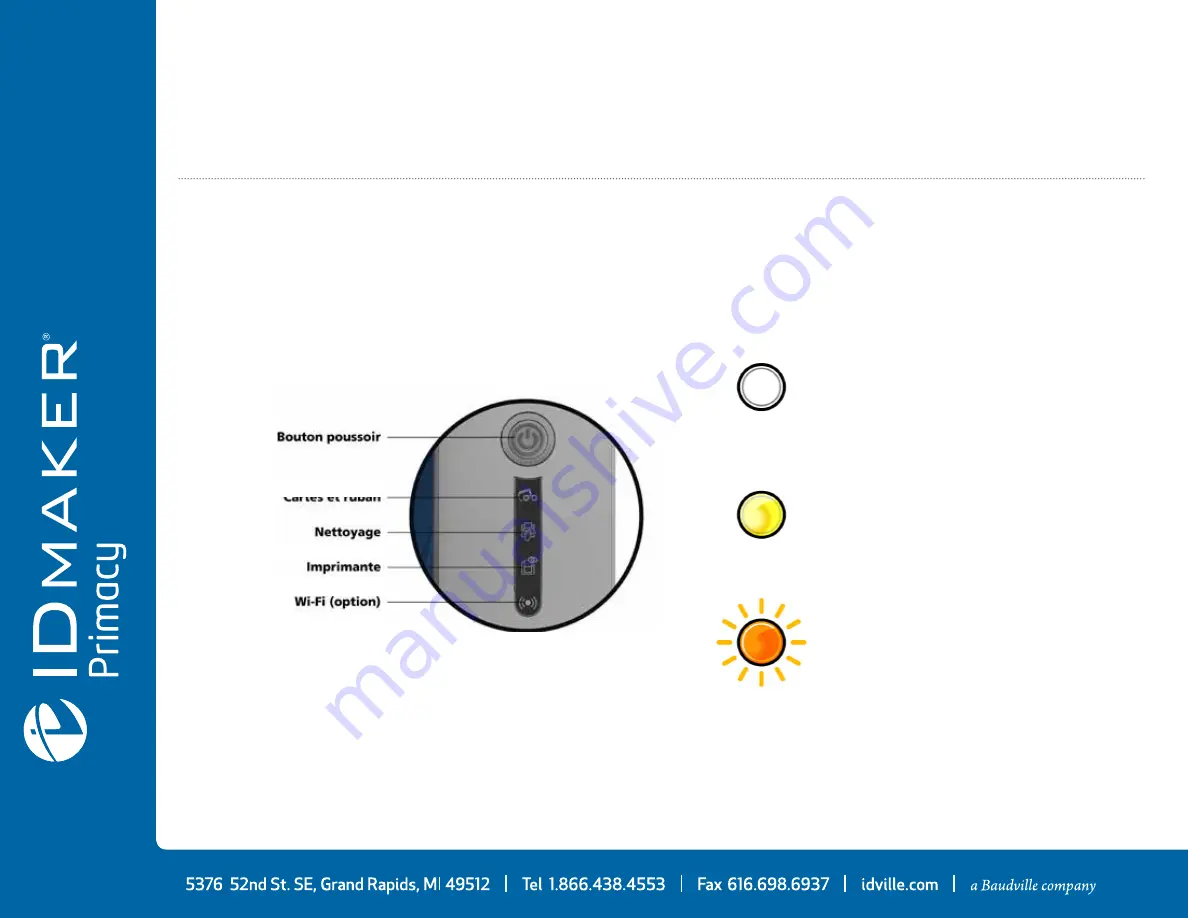

4-1a Control Panel Warnings

See

section 1 - Description of the printer and its functions

for further details about the control panel.

OFF

STEADY LIGHT

FLASHING

Pushbutton

Cards and ribbon

Cleaning

Printer