FD151 Gas Compressor 19

Figure 5.3A

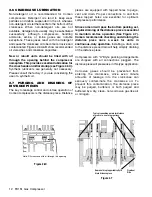

The metal valve gasket should always be replaced

when the valve is reinstalled. Make sure suction and

discharge valves are in the right slots, as shown in

the illustrations. Reinstall cages, spacers or unloader

parts and then tighten the valve hold down screw to

40 ft./lb. to ensure the valve gasket is properly

seated. Replace O-rings sealing the valve cover and

valve cap if they show any signs of wear or damage.

Reinstall valve caps sealed by flat metal gaskets with

new gaskets. Refer to Appendix C for torque values.

5.2 CYLINDERS AND HEAD

Cylinders and heads very seldom require

replacement if the compressor is properly

maintained. The primary causes of damage to

cylinders and heads are corrosion and the entry of

solid debris or liquid into the compression chamber.

Improper storage can also result in corrosion

damage to the head and cylinder (for proper storage

instructions see Section 5.8).

If the cylinder does become damaged or corroded, use

a hone to smooth the cylinder bore, and then polish it to

the value shown in Appendix D. If more than .005” must

be removed to smooth the bore, replace the cylinder.

Cylinder liners and oversized rings are not available.

Overboring the cylinder will result in greatly reduced ring

life. Note: Honing of the cylinder is not normally

recommended unless it becomes heavily scored.

Many compressor repair operations require removal

of the head and cylinder. While the compressor is

disassembled, take special care to avoid damage or

corrosion to the head and cylinder. If the compressor

will be left open for more than a few hours, coat bare

metal surfaces with rust preventative.

When reassembling the compressor, make sure the

bolts are retightened as shown in Appendix C.

5.3 PISTON RINGS AND PISTON RING

EXPANDERS

Piston ring life will vary considerably from application

to application. Ring life will improve dramatically at

lower speeds and temperatures.

Do not hone your cylinder bores unless they become

badly scratched. The piston rings will produce a

mirror-like surface which will enhance piston ring life.

To replace the piston rings: Depressurize the

compressor and purge if necessary. Remove the head

to gain access to the compressor cylinder. Loosen the

piston head bolts. Remove the piston as shown in

Figure 5.3A, by pinching two loose bolts together.

Piston rings and expanders may then be easily

removed and replaced. Corken recommends

replacing expanders whenever rings are replaced.

To determine if rings should be replaced, measure

the radial thickness and compare it to the chart in

Appendix D. Rings should be replaced if they are

near the minimum listed.

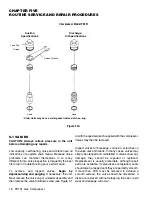

5.4 PISTONS

To replace the pistons:

Depressurize the compressor

and purge if necessary.

Remove the compressor

cylinder and head (see Section 5.2). Remove the piston

head by loosening and removing the socket head bolts

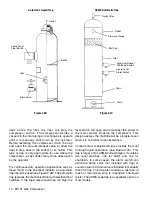

holding the piston head to the piston platform (see Figure

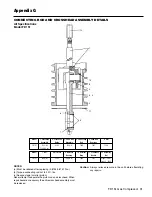

Figure 5.4A

Piston Cross-Section

sizes FD151 (First Stage Only)

Model FD151 - First Stage Only

“X”

Piston Clearnce

Roll

Pin

Piston

Bolt

Castellated

Piston Nut

Piston Ring

Expander

Piston

Ring

Cylinder

Piston

Platform

Piston Rod

Thrust

Washer

Shims

Piston Head