20

SETTINGS

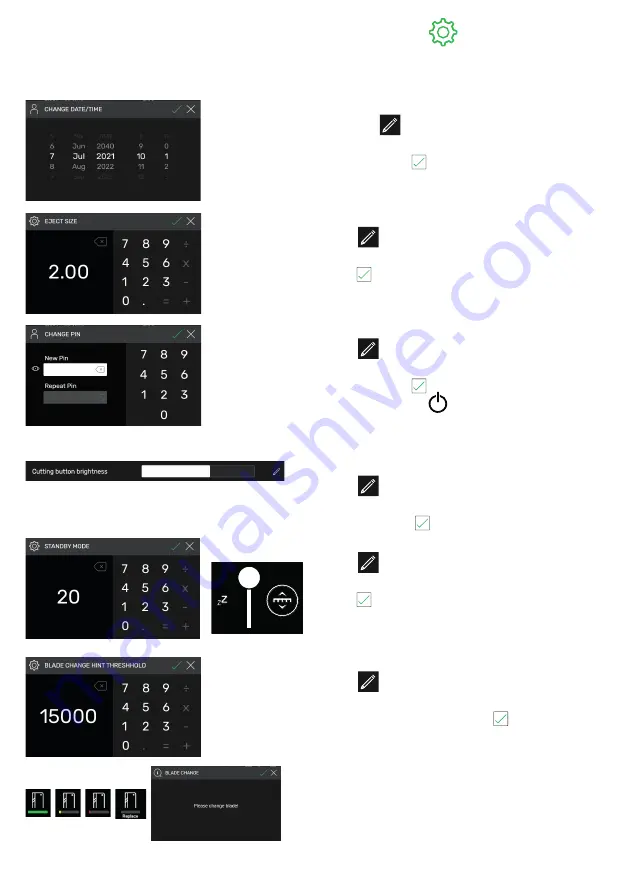

In general

Date / time

• With the

symbol open the appropriate

heading. Set by swiping upwards/ downwards

and save with .

Eject dimension (cm)

• With

open the appropriate column. Tap in

the eject dimension (max. 15.00 cm) and save

with .

Set / change user PIN

• With

open the appropriate column.

Tap in PIN (min. 4-digit / max.10-digit) twice

and save with . Unlocks the standby mode

and screen lock (

On / Off button). If no PIN

is set, then 1234 unlocks the PIN (as-delivered

state).

Cutting button brightness

• With

, activate appropriate column for

changing. Set by swiping to the left /right and

with save with .

Standby mode after (min.)

• With

open the appropriate column.

Tap in SLEEP TIMER (max. 120 min.) and save

with . Standby mode is displayed by a “zZ

Symbol” next to the operating control.

Unlock with the user PIN.

Blade change information

• With

open the appropriate column.

Tap in BLADE CHANGE WARNING LIMIT (max.

500,000 cuts) and save with .

• Under an activated application (>1), a

coloured bar indicates how many cuts could

still be carried out before replacing the blade

(an extra pointer pops up).

• Input value 0 deactivates this application.

Operating / Multi-Touch Display

Содержание THE 56

Страница 1: ...THE 56 EN Operating Instructions...