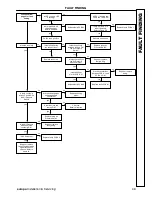

FAULT FINDING

44

europa

--- Installation & Servicing

67 FAULT FINDING

WARNING

Care must be taken when conducting fault finding tests to

guard against the risk of electric shock.

230 Vac is the nominal UK supply voltage. This may vary

between 253 Vac and 196 Vac.

When checking continuity ensure power is off to the

appliance.

With a fast pulse showing on LED 1 the boiler will continue to

operate with a reduced performance in some fault conditions.

Before commencing fault finding please check the following:

Are all wiring connections OK ?

Are the function selector settings correct

(Refer to frame 26, 27 and 30)

Are the p.c.b. jumpers correctly placed (Refer to frame 53)

yes

no

Continued on page

46 of fault finding.

Adjust the burner

pressure. refer to frame

26. Can 11.7 mbar be

achieved?

(10.5 mbar for

europa

232

)

Continued from

page 48.

Remove the motor

assembly, with 230V at

the connections is the

spindle visible? Refer

to frame 66.

Dismantle the DHW

detector valve. Refer to

frame 58 and clean.

When re---assembled

with DHW taps closed,

does the heating flow

pipe become warm?

Continued on page

45 of fault finding.

no

no

no

no

no

no

no

no

no

no

no

no

no

no

no

no

no

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

no

yes

START

Ensure the room thermostat (if fitted) and programmer are calling for heat

Also that all services are on and the selector switch is set to heating*

Is the green LED on

front facia flashing?

(1 Second on, 1

Second off)

Is the green LED on

front facia flashing4

times per second?

Is there 230V between

Live and Earth at the

mains connection in

the control box?

Rectify external

wiring fault

Is there continuity

across the fuse on the

PCB # 1?

Replace faulty

external fuse and

check for wiring

fault

With the boiler in

heating mode, is the

maximum burner

pressure 11.7 mbar

(10.5 for

europa

232

) with boiler and

system cool)

Is the gas inlet

pressure > 17 mbar?

Rectify gas supply fault

Is there 230V at the

Live connection to PCB

#1 pin 4?

Repair or replace

wiring fault

Is there 16V dc at Grey

and Black connections

on modulator coil?

Replace faulty PCB #1

Is modulator harness

continuity O.K?

Repair or replace

faulty wiring

Replace faulty PCB

#1

Adjust max ’stop’ on Gas

Valve to achieve 11.7 mbar

(10.5 mbar for

europa 232

)

Does the heating

flow pipe become

warm quickly?

Is it a

system

boiler?

Is there a

DHW tap

open?

Disconnect DHW

flow sensor wiring.

Does the heating

flow pipe now

become warm?

Is there 230V

between Blue

and Brown at

the 3---way

valve

connection?

Close

DHW

tap

Is the continuity

of the 3---way

valve harness

O.K?

Repair or

replace

faulty

wiring

Replace faulty

PCB #1

Replace faulty

motor assembly

Replace faulty valve

body assembly

Replace the DHW flow

detector sensor body.

Does the heating flow

become warm?

Faulty sensor now

replaced

Replace the faulty

DHW detector

valve

FA

U

LT

F

IN

D

IN

G