13

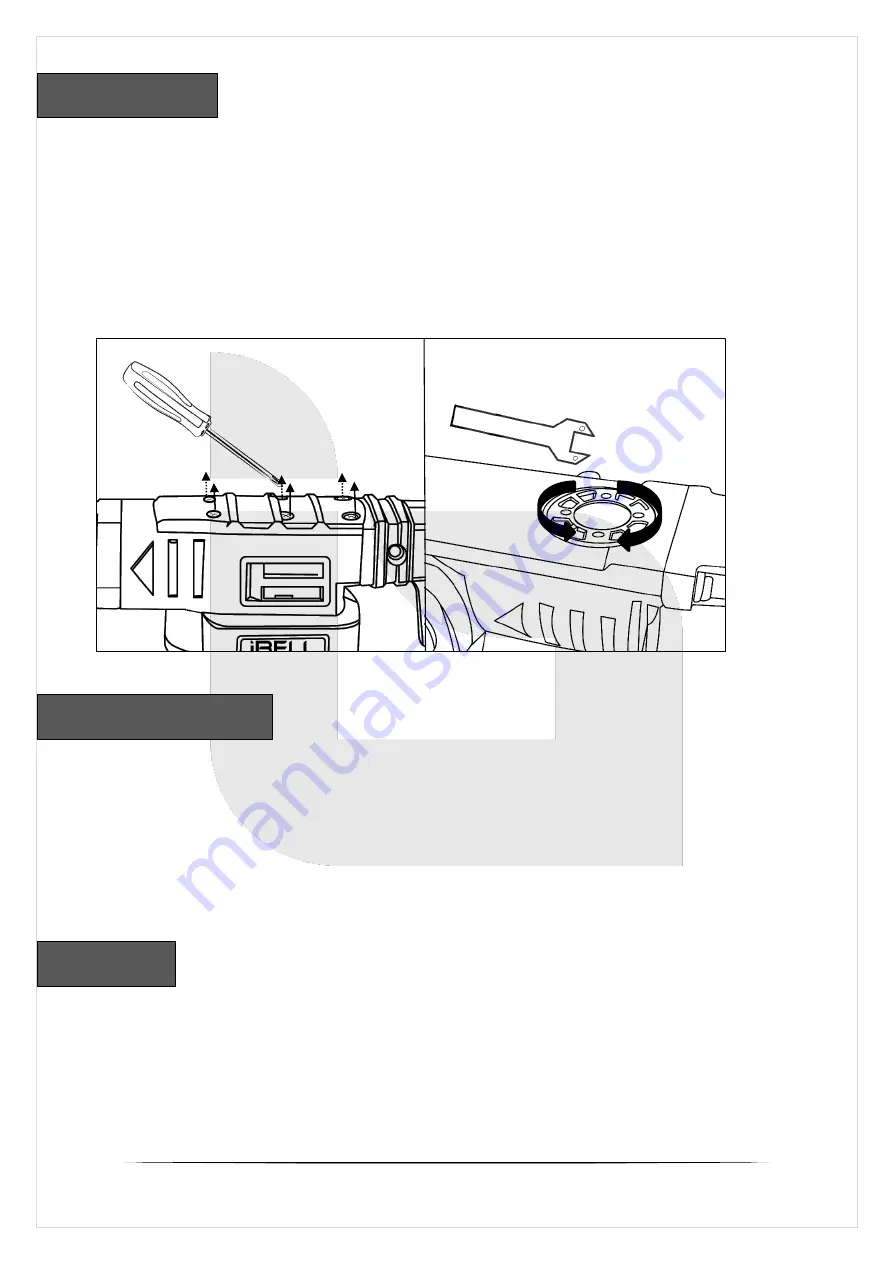

This power-tool is grease-lubricated.

Always check there is

sufficient grease in the grease box before usage.

A grease refill is only required during hammer work efficiency is

low. Open the grease box cover (5) at the top of the hammer using a

screwdriver and then a pin spanner wrench provided. Then refill the

grease provided with your tool.

The brushes and commutator in your tool have been engineered for

many hours of service. To maintain peak efficiency of the motor, we

recommend every three to six months the brushes be examined.

Only a qualified technician should conduct the replacement

. The

tool is designed to provide a qualified service technician optimal

access to replace the carbon brushes.

Every brush change, the bearings should be replaced. Bearings

which become noisy (due to heavy load) should be replaced at once

to avoid overheating or motor failure.

LUBRICATION

CARBON BRUSHES

BEARINGS

IBL DH10-78

I II