Starting Procedures

When using this product for the first time, make sure to avoid mistakes and incorrect wiring by referring to

the procedure below. “PC” stated in this section means “PC software”.

●

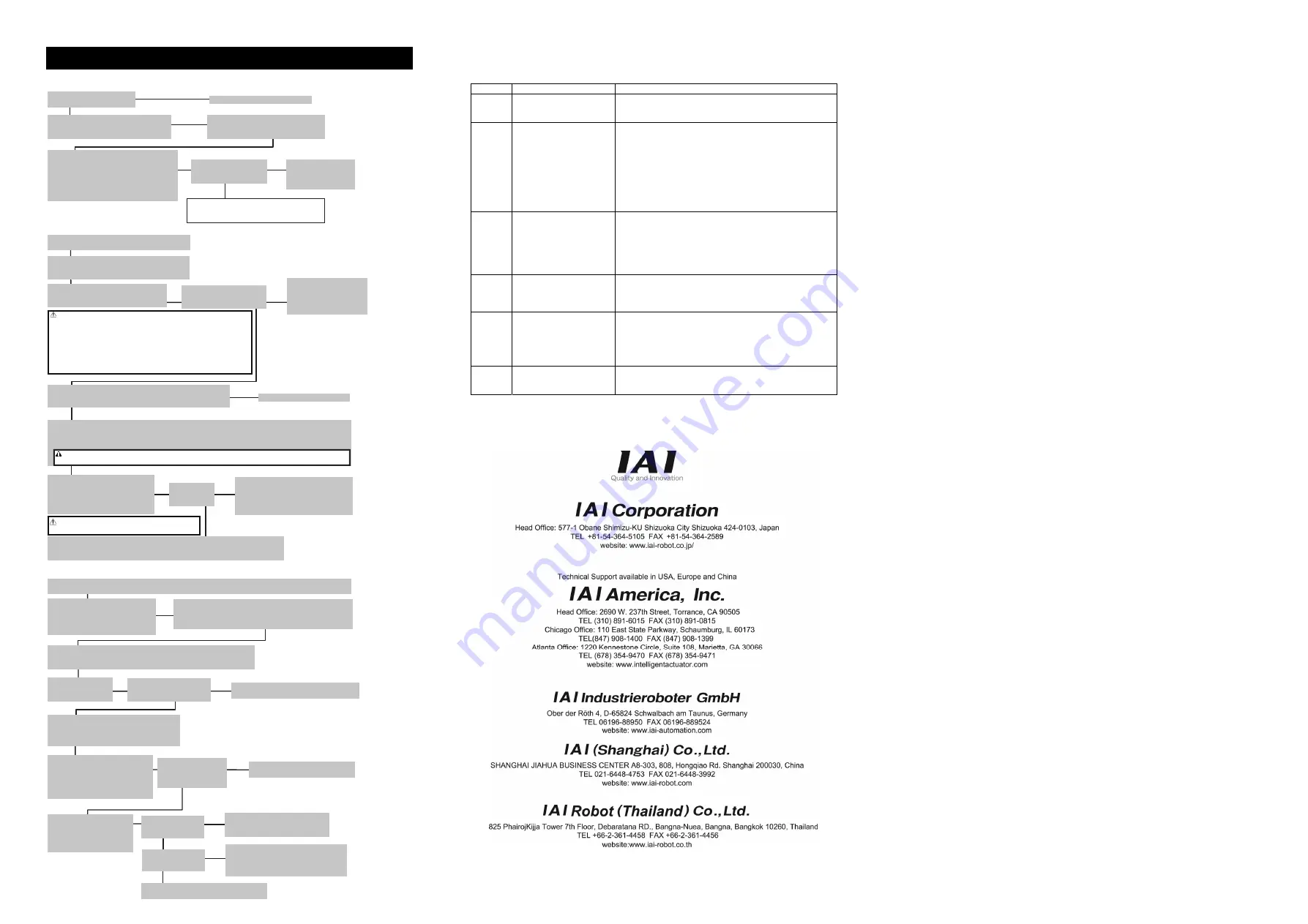

Action to Take When Error Occurred

Shown below are the alarms that you may often see after power up. Have an appropriate treatment following

the instructions below.

Please refer to the Instruction Manual for other alarms.

Error Code

Error Description

Cause and Treatment

069

Real Time Clock

Operation Stop Detection

It indicates the calendar function has stopped and the current

time data has lost.

Have the clock settings again from the teaching tool.

0B8

Excitement Detection Error

The detection of excitation is conducted when the servo is

turned ON for the first time after the power is supplied. The

status is that the detection did not complete even after a certain

time (set in Parameter No.29) was passed.

1) Connection error or wire breakage of motor/encoder cables

2) Brake is not released (when equipped with a brake).

3) Load to the motor is high due to external force.

4) Power was turned on while touching to the mechanical end.

5) The slide resistance of the actuator itself is large.

Those described above can be considered.

0E5 Encoder

Receive

Error

This error code appears when the right signal was not received

from the encoder side to the controller command. Check if any

wire breakage on a connector and the condition of wire

connections. If no error is generated under the condition that the

power to all the peripheral equipment is shut and operate only

this controller and the actuator, noise can be considered as the

cause of the problem.

0E8

A- and B-Phases

Breakage Error

It is the condition that the encoder signal is not properly

detected.

Check if any wire breakage on a connector and the condition of

wire connections.

0EE

Absolute Encoder Error

Detection 2

This error code appears when the absolute encoder PCB cannot

detect the position information properly. The voltage for the

absolute data battery is dropped. Check the battery alarm output

on PIO, and if it is off, replace the battery. Perform Absolute

Reset after the replacement.

Check the encoder cable connection.

20A

Servo OFF While in

Operation

It shows the operation command was generated in the condition

that the servo is OFF.

Resume the operation after turning the servo ON.

Manual No.: ME0288-11A

→

No →

Contact us or our distributor.

↓ Yes

No →

→

↓ Yes

← Yes

→

No →

Check Item

Is the Controller Status Display

LED turned ON in green [SV]?

Check the emergency stop circuit.

→

No →

↓ Yes

↓ Yes

↓

Check if there is any problem with the

installation of the actuator and the condition

of the actuator use exceeds the ranges of the

rated values.

Adjust the servo if necessary.

If an alarm is generated,

connect the PC or teaching

pendant and check the

content of the alarm to have

the right treatment.

Check Item

Any vibration or

abnormal noise?

No →

↓ Yes

Point Check Item

• Is frame ground (FG) connected?

• Has the noise countermeasure been taken?

Check Item

Is the Controller Status

Display LED turned OFF?

Connect the teaching tool

such as PC to confirm the

content of alarm and have

an appropriate treatment.

Have the settings and checks suitable for the used

mode selected from “Positioner Mode” and “Pulse

Train Control Mode” below.

[In the case of Positioner Mode]

Check of Packed Items

Are there all the delivered items?

Installation and Wiring

Perform the installation of and wiring for the

actuator and controller.

Power Supply and Alarm Check

Connect a teaching tool such as PC, turn the

operation mode setting switch to “MANU” side and

turn the power ON for unit.

Select [Teaching Mode 1 Safety Speed Activated /

PIO Operation Invalid] in the teaching tool such as

PC.

PIO Pattern Settings

Set the used PIO pattern to Parameter No.25.

Safety Speed Setting

Set the Parameter No.35 if necessary.

The safety speed is set to 100mm/s at the delivery.

Servo ON

Turn the servo ON with the operation on the

teaching tool such as PC.

Caution

Please perform this process with the actuator away from the mechanical end or

interfering subjects as much as possible.

Put the actuator away if it interferes with surroundings. It may generate an alarm

if the actuator hit the mechanical end or interfering subjects when the servo is

turned ON.

The slider may get slightly dropped by self-weight if servo ON and OFF is

repeatedly performed at the same position. Be careful not to pinch the hand or

damage the work.

Safety Circuit Check

Does the emergency stop circuit (drive cutoff circuit) work properly and

turn the servo OFF?

Target Position Setting

Set the target position in “Position” Box in each position table.

Perform a home-return operation first when Direct Teaching is to be performed. When moving the actuator manually, set

the Brake Release Switch to “BK RLS” side for the brake equipped type. Put the switch back after the setting is complete.

Test Run Adjustment 1

Check the operation without mounting a

work and set the safety speed invalid on

the teaching tool such as PC, and then

check the operation with a work mounted.

Caution To ensure safety, it is recommended that safety

speed be enabled during initial movements.

Test Run Adjustment 2

1) Set the operation mode setting switch to “AUTO”.

2) Output the operation command from PLC to the controller and check the system operation.

Warning Be careful not to pinch fingers or damage the work with the dropped actuator when releasing the brake

in vertical orientation.

→

Check Item

Is the minimum unit of operation set to the value bigger than the

minimum resolution of the encoder?

Is the fraction of the electronic gear ratio reduced to its lowest terms?

← Yes

→

Check Item

Is the Controller Status Display

LED turned ON in green [SV]?

No → Confirm the content of alarm on the teaching

tool such as PC to have an appropriate treatment.

← Yes

↓ Yes

→

No →

No → Check the electronic gear ratio setting.

Confirm the command pulse train input

mode setting.

Confirm that there is no problem in the

actuator installation, the actuator operation

condition demands a voltage more than rated

voltage, and appropriate pulse trains are input.

Check if there is any problem in the way

of actuator mount.

Check Item

Is there any risk of

interfering with peripheral

equipment?

No →

↓ Yes

Can the positioning

operation be performed

normally?

↓ Yes

↓ Yes

Is it in condition without

any vibration and

abnormal noise?

Test Run Adjustment 3

Check the system operation conducted by PLC.

PIO Pattern Settings

Set the used 6 “Pulse train control mode” or 7 “Pulse train control mode for Battery-less Absolute” to Parameter No.25.

Set the Electronic Gear

[Refer to Instruction Manual]

Set the electronic gear ratio based on the

amount of actuator operation per pulse in

Parameters No.65 and 66.

Pulse Train Input Output Mode Setting [Refer to Instruction Manual]

Set the command pulse train input status for the parameter No.63 and No.64.

Put Operation Mode Setting Switch to “AUTO” side when the setting is complete.

Servo ON

Input servo ON signal

from PLC.

Safety Circuit Check

Check that the emergency stop circuit (or motor

drive-power cutoff circuit) operates normally to turn

OFF the servo.

Test Run Adjustment 1

[Operation Mode MANU]

Check with a teaching tool such as the

PC software with no work being loaded,

and check the operation range with JOG

operation with the work being loaded.

Test Run Adjustment 2

[Operation Mode AUTO]

Output the pulse train from PLC

to the controller and check the

system operation.

[In the case of Pulse Train Control Mode (for PLN and PLP types only)]