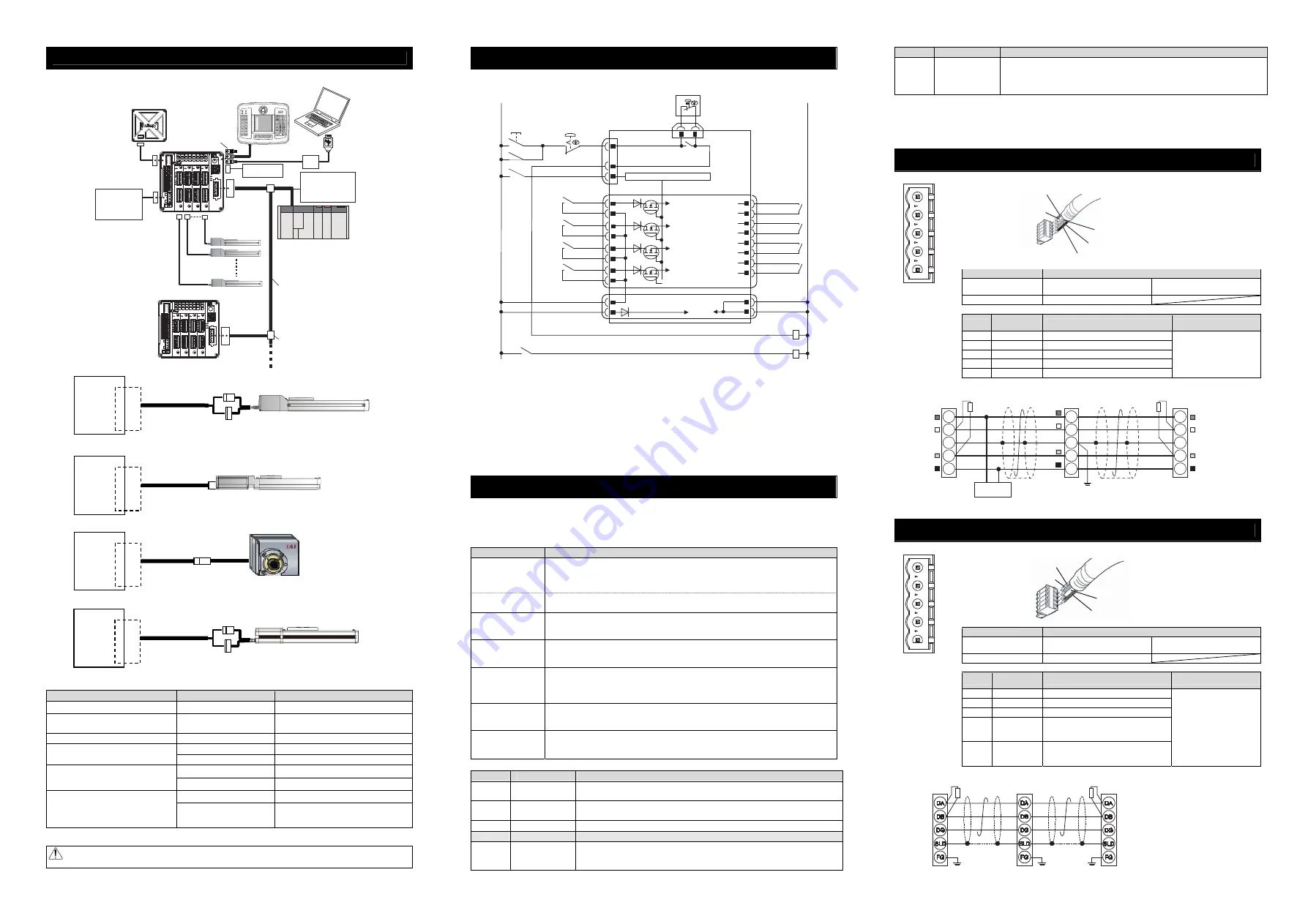

Wiring

1) Connection to RCP2 Series

2) Connection to RCP6, RCP5, RCP4, RCP3, RCA2 RCD and RCL Series

3) Connection to RCP2 Small Rotary Series

4) Connection to RCA Series

Note 1 Connection Cable Model Codes

□□□

: Cable length Example) 030 = 3m

Model

Cable Model

Remarks

RCP2 other than rotary small type

CB-PSEP-MPA□□□

Robot cable from 0.5 to 20m

RCP2 rotary small type

(RTBS/RTCS/RTBSL/RTCSL)

CB-RPSEP-MPA□□□

Robot cable from 0.5 to 20m

RCA

CB-ASEP2-MPA□□□

Robot cable from 0.5 to 20m

CB-APSEP-MPA□□□

Robot cable from 0.5 to 20m

RCP3, RCA2, RCL

CB-APSEP-MPA□□□-LC

Standard cable from 0.5 to 20m

CB-CA-MPA□□□-RB

Robot cable from 0.5 to 20m

(Note 3)

RCP4 (Other than SA3/RA3),

RCD-RA1DA(-D3)

(Note 2)

CB-CA-MPA□□□

Standard cable from 0.5 to 20m

(Note 3)

CB-CAN-MPA□□□-RB

Robot cable from 0.5 to 20m

(Note 3)

RCP6, RCP5, RCP4(SA3/RA3),

RCD-RA1DA(-D5)

(Note 2)

/ GRSNA

Gripper/Rotary of RCP2CR,

RCP2W

CB-CAN-MPA□□□

Standard cable from 0.5 to 20m

(Note 3)

Note 2

-D3/-D5 in brackets ( ) for RCD show the symbols for the applicable controllers.

Note 3 The maximum cable length for RCD is 10m for both the standard cable and robot cable.

Caution: Follow the content described in the model code record card inserted to the controller when connecting.

Wrong connection will issue an error such as the encoder wire breakage.

Power Supply and Emergency Stop Circuit

The following diagram shows an example of how the emergency stop switch for the teaching pendant may

be included in the emergency stop circuit you may construct.

EMGINSLOT0

EMGINSLOT1

EMGINSLOT2

EMGINSLOT3

Emergency Stop

Reset Switch

Emergency Stop

Switch

CR1

SIO Connector

CR1

24V

0V

Emergency Stop Control Circuit

Motor Power Supply (Slot 3)

(Axis No.6 and 7)

MPISLOT3

MPOSLOT3

CR2

(Note 2)

MPISLOT2

MPOSLOT2

CR2

(Note 2)

MPOSLOT1

MPISLOT1

CR2

(Note 2)

MPISLOT0

MPOSLOT0

CR2

(Note 2)

Motor Power Supply (Slot 2)

(Axis No.4 and 5)

Motor Power Supply (Slot 1)

(Axis No.2 and 3)

Motor Power Supply (Slot 0)

(Axis No.0 and 1)

MP+24V

0V

V

0

V

4

2

+

P

C

Control

Power

External Drive Cutoff •

Emergency Stop Input Connector

Power Line Input Connector

EMG+SLOT0

(Note 5)

S1

4

3

2

1

12

11

10

9

7

8

5

6

15

16

13

14

1

3

4

2

Emergency Stop Switch on

Teaching Pendant

S2

(Note1)

EMG A

EMG B

MCON

8

5

EMG-

EMG+SLOT1

(Note 5)

EMG+SLOT2

(Note 5)

EMG+SLOT3

(Note 5)

3

2

4

CR1

(Note 4)

CR2

(Note 2)

CR1

System I/O Connector

Operation Mode Selected (Other than Motion Network)

(Note) SSCNET

Ⅲ

/H type, MECHATROLINK-III type and EtherCAT Motion type of Motion Network is not

applicable for the operation modes listed below.

This controller possesses 7 types of operation mode to select from as the fieldbus specification.

The settings are to be established with Gateway Parameter Setting Tool.

● Operation Patterns of Fieldbus Specification

Operation Mode

Contents

Simple Direct Mode

The target position can be indicated directly by inputting a value. Also, monitoring of the

current position is available in 0.01mm unit.

Those other than the target position are to be indicated in the position table, and the setting

can be done for 256 points at maximum.

Positioner 1 Mode

The 256 points of position data can be registered at the maximum and is able to stop at the

registered positions. Also, monitoring of the current position is available in 0.01mm unit.

Direct Indication Mode

The target position, speed acceleration/deceleration and pressing current limit can be

indicated with inputting a number. Monitoring of not only the current position, but also the

current speed and indicated current are available.

Positioner 2 Mode

This is the operation mode of the position data of 256 points at maximum set in the position

table. The monitoring of the current position is not available.

This mode is that the transferred data is reduced from Positioner 1 Mode.

Positioner 3 Mode

This is the operation mode of the position data of 256 points at maximum set in the position

table. The monitoring of the current position is not available

This is the mode to control with the minimized number of signals to perform the positioning

operation by reducing the amount of sent and received data from Positioner 2 Mode.

Positioner 5 Mode

This is the operation mode of the position data of 16 points at maximum set in the position table.

It is a mode that enabled to monitor the current position in 0.1mm unit by reducing the

number of position table from Positioner 2 Mode.

Remote I/O Mode

It is the operation mode to control with ON/OFF of bits like PIO (24V input and output).

Control with five patterns, PIO Pattern 0, 1, 2, 4 and 5, is available. (Refer to Remote I/O

Operation Patterns below.)

● Remote I/O Operation Patterns (PIO patterns are to be switched over in driver board parameter No.25.)

PIO Pattern Operation Mode

I/O Type

0

Positioning

Mode

Number of positions 64 points

Zone signal output 1 point

(Note 1)

Position zone signal output

(Note 2)

1 point

1

Teaching Mode Number of positions 64 points

Position

zone signal output

(Note 2)

1 point

JOG operation available

Writing of current position to indicated position available

2

256points Mode Number of positions 256 points

Position

zone signal output

(Note 2)

1 point

3

-

Cannot be used. Make any setting will cause parameter error.

4

Electromagnetic

Mode 1

Number of positions 7 points

Zone signal output 1 point

(Note 1)

Position

zone signal output

(Note 2)

1 point

Operation indication available only by indicating position number

PIO Pattern Operation Mode

I/O Type

5

Electromagneti

c Mode 2

Number of positions 64 points

Zone signal output 1 point

(Note 1)

Position

zone signal output

(Note 2)

1 point

Operation with moving forward / moving backward / intermediate position indications

Signal output equivalent to limit switch available for complete signal

Note 1: Set the range of the zone in parameter. It becomes constantly valid once the home-return operation

is complete.

Note 2: The range of the zone is to be set in the position table, and is activated only when that position

number is indicated. It is invalid in other position number commands. The position zone signal can

be switched over to the zone signal with the setting of Parameter No.149.

DeviceNet

Type

Refer to the instruction manuals for each fieldbus master unit and mounted PLC for the details.

Connector Name

DeviceNet Connector

Cable Side

MSTB2.5/5-STF-5.08 AU M

Enclosed in standard package

Manufactured by PHOENIX CONTACT

Controller Side

MSTB2.5/5-GF-5.08 AU

Pin No.

Signal Name

(Color)

Description

Applicable cable diameter

1

V- (BK)

Power Supply Cable Negative Side

2

CAN L (BL)

Communication Data Low Side

3

Shield (None)

Shield

4

CAN H (WT)

Communication Data High Side

5

V+ (RD)

Power Supply Cable Positive Side

Dedicated cable for

DeviceNet

Slave Devices

MCON-DeviceNet Type

V+

Drain

(Shield)

CAN_H

CAN_L

V-

RD

WT

BL

BK

RD

WT

BL

BK

V+

Drain

(Shield)

CAN_H

CAN_L

Grounding resistance at 100

Ω

or less

(Class D grounding)

V+

Drain

(Shield)

CAN_H

CAN_L

V-

RD

WT

BL

BK

Communication power needs to be

supplied by an external device.

Terminal Resistance is required

to be mounted on the terminal.

V-

Terminal Resistance

121

Ω

Master Unit

Terminal Resistance

121

Ω

24V

Power Supply

CC-Link Type

Refer to the instruction manuals for each fieldbus master unit and mounted PLC for the details.

Connector Name

CC-Link Connector

Cable Side

MSTB2.5/5-STF-5.08 AU

Enclosed in standard package

Manufactured by PHOENIX CONTACT

Controller Side

MSTB2.5/5-GF-5.08 AU

Pin No.

Signal Name

(Color)

Description

Applicable cable diameter

1

DA (BL)

Communication Line A

2

DB (WT)

Communication Line B

3

DG (YW)

Digital GND

4

SLD

Connect the shield of the shielded cable

(Connect the FG of the 5 pins and

controller FG internally)

5

FG

Frame Ground

(Connect the SLD of the 4 pins and

controller FG internally)

Dedicated cable for CC-Link

MCON

AX0 to 7

Actuator

Connector

MCON

AX0 to 7

Actuator

Connector

MCON

AX0 to 7

Actuator

Connector

MCON

AX0 to 7

Actuator

Connector

Connection Cable

(Note 1)

Connection Cable

(Note 1)

Connection Cable

(Note 1)

Connection Cable

(Note 1)

1

2

3

4

5

Front View of

Connector on

Controller side

Shield

BL (CAN L)

RD (V+)

WT (CAN H)

BK (V-)

1

2

3

4

5

Front View of

Connector on

Controller side

WT (DB)

BL (DA)

Shield (SLD)

YW (DG)

Note 1 MCON-C: When there is nothing plugged in the SIO connector, S1 and S2 are short-circuited inside

the controller.

MCON-CG: When there is nothing plugged in the SIO connector, S1 and S2 are not short-circuited

inside the controller.

When the short-circuited, the enclosed dummy plug DP-5 plugged in the SIO connector.

Note 2 When the motor driving source is cut off externally for a compliance with the safety category, relay a

contact such as a contactor to the wires between MPISLOT

and MPOSLOT

.

Note 3 The rating for the emergency stop signal (EMG-) to turn ON/OFF at contact CR1 is 24V DC and 10mA.

Note 4 For CR1, select the one with coil current 0.1A or less.

Note 5 By cutting out the connection between EMG+SLOT

and EMGINSLOT

, only the disconnected slot

number can be made in the condition of an emergency stop. (

: Slot Number)

(Note) If supplying power with using a 24V DC, having it turned ON/OFF, keep the 0V connected and have the

+24V supplied/cut (cut one side only).

Slave Devices

MCON-

CC-Link

Type

SLD and FG are internally connected.

Terminal Resistance is required

to be mounted on the terminal.

The terminal resistor differs depending on the type

of the dedicated cable for CC-Link.

• Cable FANC-SBH···130

Ω

1/2W

(High Performance Cable

dedicated for CC-Link)

• Cable FANC-SB······110

Ω

1/2W

(CC-Link Dedicated Cable)

Master Unit

Terminal

Resistance

Terminal

Resistance

Grounding resistance at 100

Ω

or less

(Class D grounding)

Teaching Pendant

Touch Panel Teaching

(to be purchased separately)

Host System (Master Unit)

(PLC, etc.…Please prepare separately)

Communication power

supply (if necessary)

(24V DC

…Please prepare

separately)

Actuator

Emergency Stop

Circuit

Control/Drive Power

Supply

(24V DC

…Please prepare

separately)

PC software

(to be purchased separately)

Absolute Battery Box

Each Fieldbus

communication cable

Follow the specifications of

each Fieldbus for how to

lay out wiring.

For MCON-CG,

in case a teaching

tool is not connected

to SIO connector,

have the enclosed

dummy plug (DP-5)

plugged in the connector.