OPERATING PROCEDURES

43

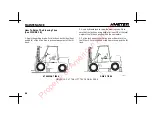

If the weight of the load is not centered between the forks,

the load can fall from the forks when you turn a corner or

hit a bump. An off--center load will increase the possibility

of the truck tipping over to the side.

Make sure the pins that keep the forks in position are en-

gaged so that the forks cannot move.

4. For carriages or attachments that can be sideshifted,

the load should be centered on the centerline of the lift

truck before the load is transported. Capacities listed un-

der “Centered” on the Nameplate apply when transporting

loads that are centered on the centerline of the lift truck.

Capacities listed under “Sideshifted” on the Nameplate

apply if loads are transported that are not centered on the

centerline of the lift truck.

5. Check the condition of the driving surface. Make sure

the floor will support the weight of the lift truck and the

load.

Load Handling, Lifting, Lowering, And Tilting

The

LIFT

and

TILT

functions are con-

trolled by separate levers. See the

In-

struments and Controls

section for

the correct operation.

The speed of the hydraulic functions is con-

trolled by the position of the control levers and

the speed of the engine. The farther the hand

lever is moved from the

NEUTRAL

position, the

faster the speed of the hydraulic function.

Do not lift or hit anything that can fall on the operator or a

bystander. Remember, a lift truck equipped with a HYS-

TER overhead guard and load backrest extension pro-

vides reasonable protection to the operator from falling

objects, but can not protect against every possible impact.

Property of American Airlines