HyQuest Solutions Pty Ltd

WS200/WS300/WS500

Page

4 of 28

©

Copyright

OPERATION

The current meter can be fitted with a stabiliser tail fin which is attached to a hanger bar and

Colombus gauging weight in sizes of 7, 15, 23, 34, 45 and 68 Kg. This assembly is suspended from

the WS250/400/500 gauging winch with armoured signal cable.

HyQuest Solutions provides a range of counters to operate with the WS250/400/500 winch. The

models available are CMC20A, CMCsp, PVD100

, PVD200

and the Hydro

Tab/CMCbt android

device.

Initial

set

up:

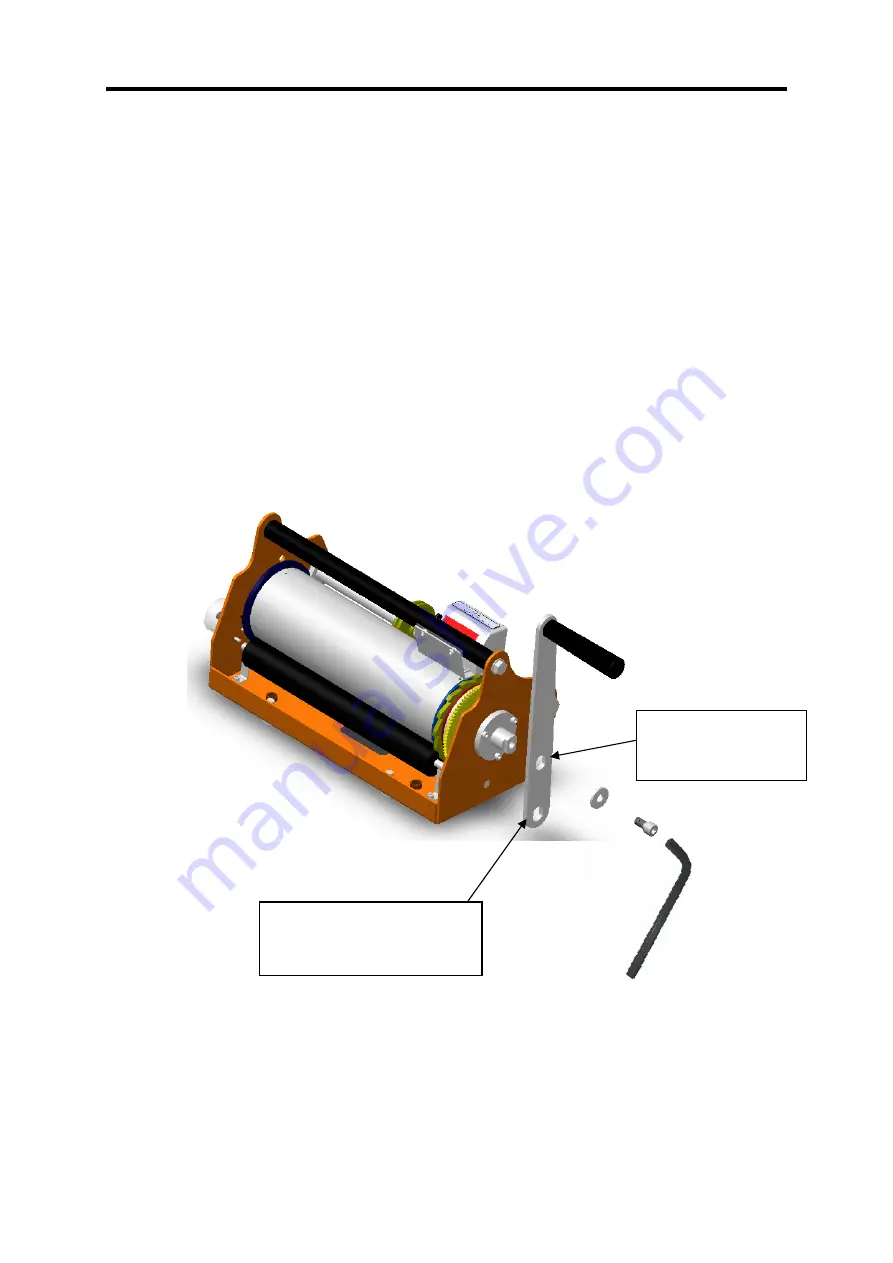

Remove the winch from the carry case.

Fit handle, washer and M10 retaining screw onto the shaft of the winch. Use the supplied

“

Allen Key”

to tightly lock the retaining screw.

For light gauging

weights use this

position on the handle

For heavy gauging weights,

use this position on the handle

to gain more torque

ISSUE 3:11/6/19