Repair Instructions

4

Note that these bolts have seal washers on them and

must not be damaged. From the backside of the casing

cover, press the mechanical seal out and discard it.

Clean-up of Pump Housing

If necessary, clean the pump casing, volute, and casing cover

using a solvent to remove debris and corrosion particles. Use

a wire brush to further remove buildup of debris if it doesn’t

soak loose.

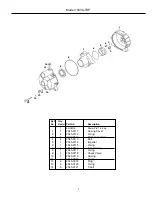

Seal Replacement and

Pump Housing Assembly

1. Apply a light bead of RTV sealant to the top edge of the

seal cavity on the casing cover.

2. Insert the stationary portion of the new mechanical seal

by carefully pushing only on the outer metal ring as you

press it into the casing cover. Use a tool with 1 1/2" ID,

such as a 1 1/2" PVC pipe, 4" long, that fits over the

carbon face of the seal, but pushes only on the metal ring

to insert the seal. Be careful to avoid scratching the seal’s

carbon surface.

3. Bolt casing cover on engine. Note the arrow and word UP

to indicate orientation of the casing cover. Use bolts with

washers on them. Install o-ring on casing cover; replace

with a new o-ring if necessary.

4. Lubricate the seal cavity of the impeller with WD-40,

LPS, or equivalent, and carefully press the seal’s

mating ceramic ring in place, seating it squarely on the

bottom of the cavity.

IMPORTANT: MAKE SURE

BOTH OF THE SEAL’S SURFACES ARE CLEAN

AND LUBRICATED. NEVER RUN THE SEAL

SURFACES DRY.

5. Place the impeller on the shaft and spin it clockwise to

tighten it on the shaft. Secure the impeller using a

socket and wrench (see step 3 in Disassembly

Instructions for socket size).

6. It is now necessary to check the clearance between the

impeller and volute. As shown in the sketch below,

measure the inside depth of the volute case (distance A).

Then measure the distance from the casing cover to the

front edge of the impeller (distance B). The difference

between the two measurements should be between 0.024

and 0.036" or about 1/32" clearance. If the value is out

of range, remove the impeller and adjust by adding or

removing brass shims to achieve the correct amount of

clearance.

7. Place a new o-ring in the groove of the volute’s inlet if

necessary. Place the volute in place with the notch pointing

up so that it mates with the casing cover at the inlet port. It

may be necessary to tip the engine on its side for this

assembly.

8. Carefully set casing over volute and bolt casing onto casing

cover and frame. It may be necessary to tip the engine on

its side for this assembly.

9. Once assembly is complete, pull on engine recoil starter

with engine switch in OFF position to verify that the impeller

rotates smoothly without catching. Connect spark plug

wire. Assembly and inspection is now complete.

(Repair Instructions Continued)

A

B

Casing

Cover

Impeller

Volute

(A) – (B) = within 0.024 - 0.036 inches.