Operation and Maintenance

(Operation and Maintenance Continued)

Always flush pump with water or neutralizing agent

before servicing.

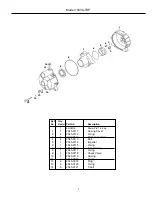

Pump Housing Disassembly

For this pump model, seal replacement requires that the

pump be fully removed from the engine. Observe carefully

the disassembly process, (orientation and order of part

assembly) to ensure an easy assembly process.

1.

Pull spark plug wire off spark plug for safety

considerations.

Remove the four bolts holding the

casing to the casing cover and frame using a 14mm

socket wrench. Tap pump casing on the discharge port

with a rubber hammer, if necessary, to break it loose

from the casing cover. Check inside pump casing. If

badly eroded or damaged, pump casing should be

replaced. Remove O-rings from casing cover and volute.

2. Remove volute and inspect for wear. Replace if eroded.

3. Remove impeller by turning it counterclockwise using a

socket and impact wrench. If an impact wrench is not

available, it may be necessary to hold the crankshaft

from turning. To keep the crankshaft from turning during

disassembly, remove the three bolts holding the recoil

starter using a 10mm socket wrench. Then, using a

pipe wrench or another tool, hold the starter hub and

spin the impeller off. Look for shims that may be

present between the impeller and shaft. This shim is for

obtaining the proper clearance between the impeller

and volute. Be careful not to damage the starter hub

while gripping it with the wrench.

4. Between the impeller and casing cover is the

mechanical seal. On the backside of the impeller is the

seal’s ceramic seat. If either part of the seal is

damaged, with cracked or scuffed surfaces, the seal

will fail to perform satisfactory and will leak. To remove

the seal seat from the impeller, use a small blade

screwdriver and wedge the seal seat out and discard.

To remove the mechanical seal, it is necessary to first

remove the casing cover by removing the four bolts

holding it to the engine, using 13mm socket wrench.

Stopping the Pump

1. Stop pump for a short time:

Run engine throttled all the way down (fully to the right).

Turn engine switch to OFF position.

2. Stopping pump for storage:

Turn fuel cock to OFF position instead of turning the

engine switch off.

Let the engine idle for 2 to 3 minutes until fuel in

carburetor is depleted and engine stops. If a valve is

installed on the discharge hose, you may run pump

with valve closed during this procedure.

Note: Pump must not be run dry. Make sure there is

water in the priming chamber.

Storage

1. Drain pump. Flush Pump after Use.

One of the most common causes for faulty pump

performance is gumming or corrosion inside the pump.

Flush the pump and entire system with a solution that

will chemically neutralize the liquid pumped. Mix

according to the manufacturer’s directions. This will

dissolve most residues remaining in the pump, leaving

the inside of the pump clean and ready for use.

To Prevent Corrosion:

After cleaning the pump as directed above, flush it with

permanent-type automotive antifreeze (Prestone,

Zerex, etc.) containing a rust inhibitor. Use a 50%

solution; half antifreeze and half water, or fill the pump

with FLUID FILM and drain it. A protective coating of

FLUID FILM will remain on the inner pump surfaces.

Save the excess FLUID FILM for the next application.

Plug ports to keep out air during storage. For short

periods of idleness, noncorrosive liquids may be left in

the pump, BUT AIR MUST BE KEPT OUT. Plug the

ports or seal port connections.

2. Drain all the fuel from the fuel tank, fuel lines, and filter.

3. Store pump in a clean, dry environment.

3

Repair Instructions