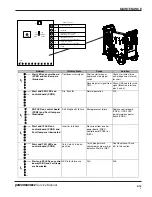

This May Mean

Cause

Solution

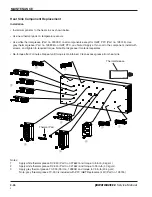

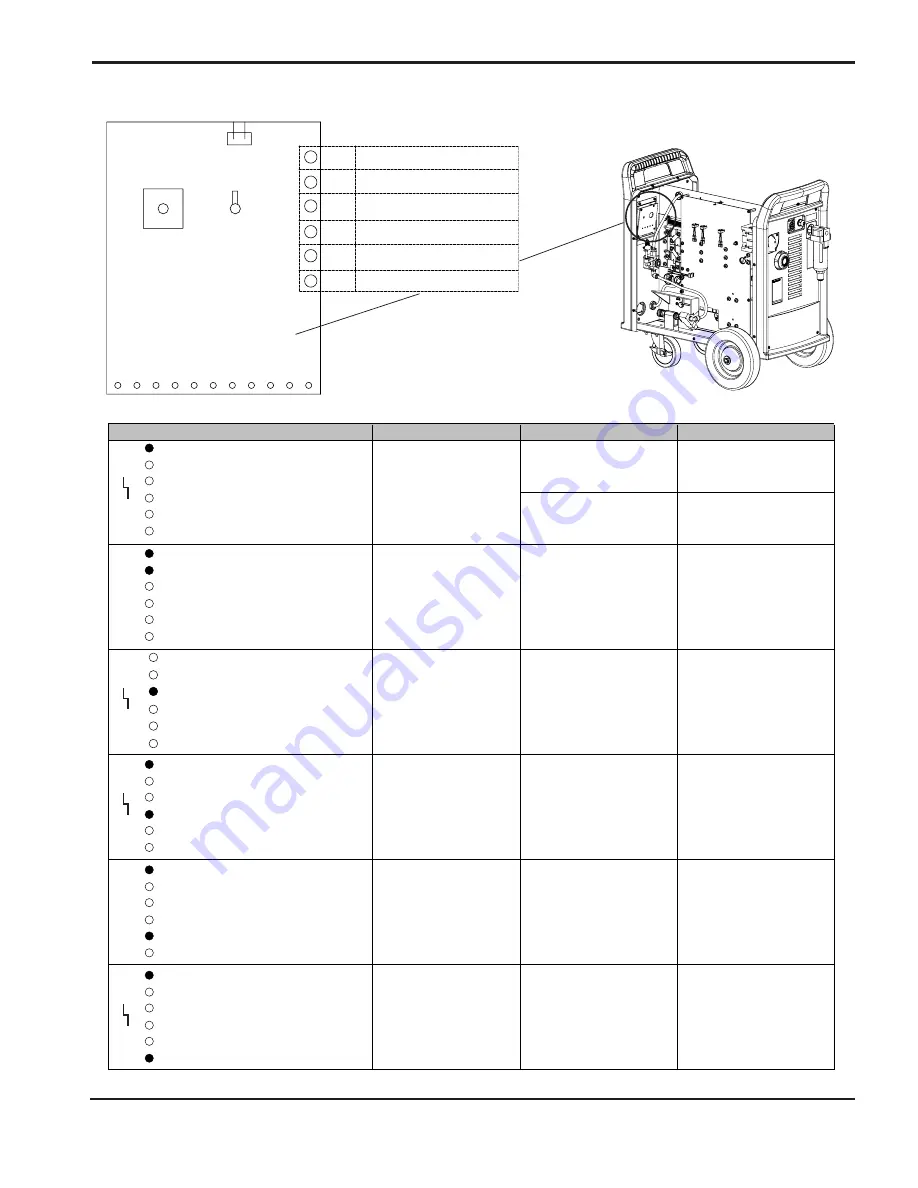

Start LED on control board

(PCB3) and Fault lamp are

illuminated

Continuous start signal

Shorted start wires or

depressed start trigger

switch

Check start wires (blue

and orange wires in torch)

for short.

Receiving start signal from

CNC

Check CNC cable for start

signal (Machine interface

pins 3 and 4).

Start and XFR LEDs on

control board (PCB3)

Arc transfer

Normal operation

N/A

SDF LED on control board

(PCB3) and Fault lamp are

illuminated

Self diagnostic failure

Microprocessor failure

Replace control board

(PCB3). If SDF LED

persists replace power

board (PCB2).

Start and IF LEDs on

control board (PCB3) and

Fault lamp are illuminated

Invertor interlock

No current from invertor,

power board (PCB2),

control board (PCB3), or

IGBTs

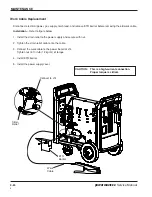

Start and TSO LEDs on

control board (PCB3)

Torch stuck in open

position

Torch plunger stuck,

consumables are worn, or

defective Pilot Arc IGBT

See Resistance Check

#3, in this section.

Start and SP LEDs on control

board (PCB3) and Fault lamp

are illuminated

LED is for future use

N/A

N/A

Problem

MAINTENANCE

powermax1650

Service Manual

3-13

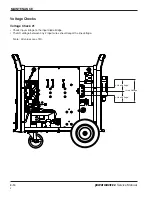

0

(VISIBLE FOR 10 SEC. AFTER EVENT)

TORCH STUCK OPEN

(VISIBLE FOR 10 SEC. AFTER EVENT)

70

50

STATUS

GAS

45

60

55

65

75

80

85

TSO

SP

SPARE

DIAGNOSTIC LED'S

START SIGNAL VALID

INVERTER INTERLOCK

(BLINKING @ 1 SEC. RATE)

SELF DIAGNOSTICS FAILURE

CPA

NORMAL

GOUGE

CURRENT

DOWN

MID

UP

P1

XFR

SDF

IF

TRANSFER

START

START

XFR

START

SDF

IF

START

TSO

START

SP

START

Содержание Powermax 1650

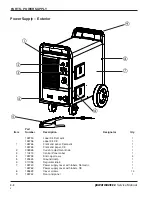

Страница 27: ...2 8 powermax1650 Service Manual SPECIFICATIONS 0 ...

Страница 61: ...PARTS POWER SUPPLY 4 8 powermax1650 Service Manual 0 ...

Страница 64: ...PARTS TORCH AND CONSUMABLES powermax1650 Service Manual 5 3 0 ...

Страница 66: ...PARTS TORCH AND CONSUMABLES powermax1650 Service Manual 5 5 0 ...